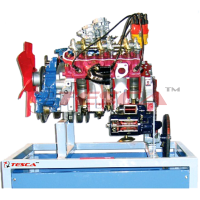

Whole Vehicle Electric Training Platform.

Order Code: AET16

Category: Automobile Engineering Lab

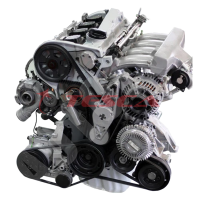

Product Introduction The whole vehicle electrical training platform is based on the vehicle electrical object, fully, display the automobile engine anti-theft system, instrument system, lighting system, wiper system, horn system, ignition...

SPECIFICATION

Product Introduction

The whole vehicle electrical training platform is based on the vehicle electrical object, fully, display the automobile engine anti-theft system, instrument system, lighting system, wiper system, horn system, ignition system, electric window system, electric door lock, sound system, starting system, and charging system and other automotive electrical systems of the composition of the structure and working process.

Technical Specification

- Power supply: three-phase four-wire (or three-phase five-wire) 380V +10% 50Hz

- Operating voltage: DC 12V , Operating temperature: 40°C ~ +50°C

- Three phase synchronous motor voltage : AC 220V /380V

- Power 2.2KW, Rotational Speed : 1420r/min

- Steel pipe :40*40*3mm

- Cabinet : 1.5mm cold plats is pressed and formed, and a maintenance door is set on the back

- Moving casters : 100*60mm

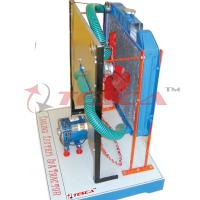

Features

- The Equipment panel is made of advance aluminum-plastic plate which is resistence to impact, pollution, fire and moisture, and the surface is treated by special process spraying primer: Panel printed with color circuit diagrams that never fade; Students can directly compare the circuit diagram and the object, understand and analyze the working principle of the electrical system of the vehicle.

- The panel part of the equipment adopts 1.5mm cold plate stamping structure beautiful appearance.

- Detection terminals are installed on the panel of the teaching board, which can directly detect the electrical signals of the circuit components of the electrical system of the vehicle such as resistence, voltage current frequency signals, etc.

- The bottom frame is welded with steel structure, and the surface is sprayed with self-locking caster device.

- A diagnostic seat is installed on the device panel which can be connected to special or general vehicle decoder, and carry out ECU coding query fault code reading fault code clearing data stream reading component testing, parameter setting waveform analysis key matching and other self-diagnostic function for engine control unit combined instrument and comfort system unit.

91-9829132777

91-9829132777