Universal Testing Equipment

Order Code: 2223822.9

Category: General Lab Equipment I

Maximum capacity : 1000kN Measuring range : 0-1000kN Load resolution (20000 counts full scale) : 50N Load range with accuracy of meas +/- 1% : 20 to 1000kN Resolution of piston movement (displacement) : 0.1mm ...

SPECIFICATION

-

Maximum capacity : 1000kN

-

Measuring range : 0-1000kN

-

Load resolution (20000 counts full scale) : 50N

-

Load range with accuracy of meas +/- 1% : 20 to 1000kN

-

Resolution of piston movement (displacement) : 0.1mm

-

Clearance for tensile test (at fully descended working piston) : 50-850mm

-

Clearance for compression test (at fully descended working piston) : 0-850mm

-

Clearance between columns : 750mm

-

Ram stroke : 250mm

-

Straining/ piston speed (at no load) : 0-80mm/min

Connected Load :

-

Power : 3.5hp

-

V : 400-440V

-

Φ : 3

Features :

-

Loading accuracy as high as + 1%

-

Straining at variable speeds to suit a wide range of materials.

-

Printer & pc graphs enables to study the behavior of the material.

-

Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen.

-

Simplicity in reading because of digital readouts.

-

Wide range of standard and special accessories, including load stabilizer

-

Easy change from plain to threaded and screwed specimens.

-

Large effective clearance between columns enables testing of standards specimens as well as structures.

-

Simple controls for ease of operation.

-

Robust straining frame of an extremely rigid construction.

-

Safe operation ensured by means of safety devices.

-

Fully enclosed and protected pressure transducer.

-

RS 232 serial port to transfer data to computer for analysis/storage evaluation etc.

Application :

-

Electronic universal testing machine is designed for testing ferrous & non-ferrous materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also conducted.

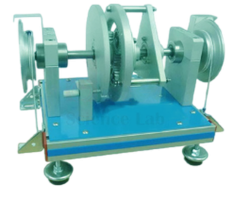

Straining Unit :

-

This consists of a cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic cylinder, mounted on to a robust base.

-

The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is rigidly fixed to the table by two strengthened columns.

-

The lower cross-head is connected to two screwed columns which are driven by a motor. Axial loading of the ram is ensured by relieving the cylinder and ram of any possible side loading by the provision of ball seating.

-

A rotary encoder of minimum resolution 0.1mm is provided to measure the deformation of the specimen. Tension test is conducted by gripping the test specimen between the upper and lower cross-heads.

-

Compression, transverse, bending, shear and hardness tests are conducted between the lower cross-head and the table.

-

The lower cross-head can be raised or lowered rapidly by operating the screwed columns, thus facilitating ease of fixing of the test specimen.

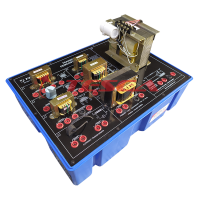

Control Panel :

-

The control panel consists of a power pack complete with drive motor and an oil tank, control valves and electronic display unit.

Power Pack :

-

The power pack generates the maximum pressure of 200 kgf/cm2. The hydraulic pump provides continuously non-pulsating oil flow. Hence the load application is very smooth.

Hydraulic Controls :

-

Hand operated wheels are used to control the flow to and from the hydraulic cylinder.

-

The regulation of the oil flow is infinitely variable. Incorporated in the hydraulic system is a regulating valve, which maintains a practically constant rate of piston movement. Control by this valve allows extensometer reading to be taken.

91-9829132777

91-9829132777