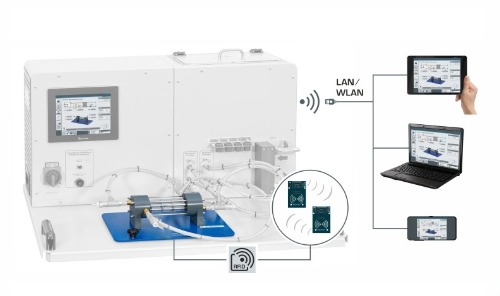

Tubular Heat Exchanger (To be used with: Power Supply For Heat Exchangers) TUBULAR HEAT EXCHANGER (To be used with: POWER SUPPLY FOR HEAT EXCHANGERS). Features- visible flow channel due to transparent outer tube,- intuitive experiment execution via touch screen ,- integrated router for operation and control via an end device and for screen mirroring on up to 10 end devices: PC, tablet, smartphone,- automatic identification of accessories via RFID technology. Learning objectives/ experiments- i

Order Code: 24258098.51

Category: General Lab Equipment V

TUBULAR HEAT EXCHANGER (To be used with: POWER SUPPLY FOR HEAT EXCHANGERS). Features visible flow channel due to transparent outer tube,- intuitive experiment execution via touch screen ,- integrated router for operation and control via a...

SPECIFICATION

TUBULAR HEAT EXCHANGER (To be used with: POWER SUPPLY FOR HEAT EXCHANGERS).

Features

-

visible flow channel due to transparent outer tube,- intuitive experiment execution via touch screen ,- integrated router for operation and control via an end device and for screen mirroring on up to 10 end devices: PC, tablet, smartphone,- automatic identification of accessories via RFID technology.

-

Learning objectives/ experiments- in conjunction with supply unit,--function and behaviour during operation of a tubular heat exchanger,-- plotting temperature curves: in parallel flow operation,in counterflow operation,-- calculation of mean heat transfer coefficient,-- comparison with other heat exchanger types, - PLC software specifically adapted to the accessories used, -- learning module with theoretical fundamentals,--device description,-- guided experiment preparation,--execution of the experiment,-- graphical representation of the experimental section with measured values for temperature,--data transfer via WLAN/LAN for versatile external use of measured values and screenshots e.g. evaluation in Excel.

Specification

-

tubular heat exchanger for connection to base unit

-

parallel flow and counterflow operation possible

-

recording of temperature using base unit and two additional temperature sensors for measuring the central temperature

-

automatic identification of accessories via RFID technology and use of the corresponding PLC software

-

experiment execution and display of the measured values via touch screen (HMI)

-

screen-mirroring: access to ongoing experiments and their results from up to 10 end devices simultaneously via the local network

-

hot and cold water supply from base unit. Technical data: Heat transfer surfaces,- mean transfer surface: 250cm2. Inner tube, stainless steel,- Ø outer: 12mm,- wall thickness: 1mm. Outer tube, transparent (PMMA),- Ø outer: 20mm,- wall thickness: 2mm . Measuring ranges,- temperature: 2x 0...100°C

91-9829132777

91-9829132777