Thermal Expansion Training Unit

Order Code: 32388

Category: Thermodynamics Lab

Most solid materials expand upon heating and contract when cooled. Materials generally change their size when subjected to a temperature change while the pressure is constant. In the case of solid materials, the pressure does not appreciably affect t...

SPECIFICATION

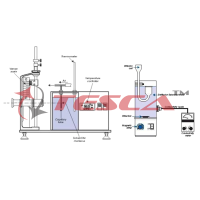

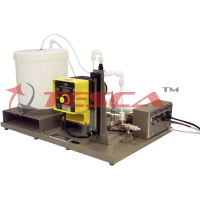

Most solid materials expand upon heating and contract when cooled. Materials generally change their size when subjected to a temperature change while the pressure is constant. In the case of solid materials, the pressure does not appreciably affect the size of a solid. Thermal expansion is a material property that indicative the tendency of the material to change in volume in response to a change in temperature. Different materials expand by different amounts Thermal Expansion Training Unit 32388 allows to study the thermal expansion of different pipe sections and the thermal expansion force. It comprises original components as used in heating and sanitation systems. This unit provides measurements for the determination of the thermal expansion of several pipe sections. The unit includes six pipe sections and one of these sections is fitted with an expansion compensator to compensate thermal stress in the pipe.

These sections are made of different materials and diameters. Several dial gauges situated on the pipe sections inlet measure the elongation of the pipes and a force measuring device allows to determine the thermal expansion force. The pipe sections can be individually selected using the ball valves situated at the pipe section outlet. The cold and hot water connections made using quick-release couplings. The water inlet temperature can be adjusted by these connections and a mixing faucet. The inlet and outlet lines include two temperature sensors to measure the change of temperature.

Specifications

Anodized aluminum frame and panels made of painted steel. The unit includes wheels to facilitate its mobility. Main metallic elements made of stainless steel.

Diagram in the front panel with distribution of the elements similar to the real one.

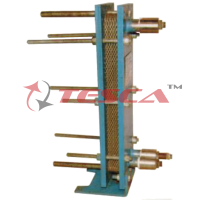

Six pipe sections: Length: 1000 mm, each one.

Stainless steel pipe section with an external diameter of 1/2”. Copper pipe section with an external diameter of 10 mm.

Copper pipe section with an external diameter of 18 mm.

PVC pipe section with an external diameter of 20 mm.

PVC pipe section with an external diameter of 15 mm with an expansion compensator to compensate thermal stress in this section.

PE pipe section with an external diameter of 20 mm.

Six ball valves: Five ball valves to select the pipe sections. A ball valve situated in the water inlet line.

A thermostatic mixing faucet to adjust the water inlet temperature.

Five dial gauges to measure the elongation of the pipe sections.

A force measuring device to determine the thermal expansion force.

Two “J” type temperature sensors situated in the water inlet and outlet lines.

Water connections made using quick-release couplings.

Electronic console: Metallic box.

Temperature sensors connections.

Selector for temperature sensors.

Digital display for temperature sensors.

ON/OFF main switch.

Cables and Accessories, for normal operation.

Manuals: This unit is supplied with the following manuals: Required services, Assembly and Installation, Starting-up, Security, Maintenance and Practices manual.

Experiments

Measurement of the pipe sections elongation.

Determination of the thermal expansion of different materials such as stainless steel, copper, PVC and PE.

Study of the effect of varying pipe diameter in the thermal expansion.

Determination of the thermal expansion coefficients.

Determination of the thermal expansion force.

Study of the expansion compensator.

Required Services

Electrical supply: single-phase, 220 V/50 Hz.

Water supply and drain.

91-9829132777

91-9829132777