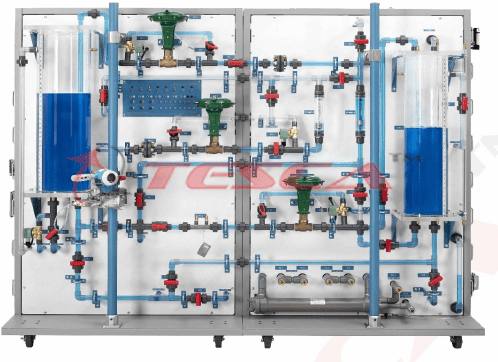

Teaching station of continuous processes: temperature, level, flow, pressure.

Order Code: 24257986.5

Category: General Lab Equipment V

Purpose: The training set is designed for the practical education of students in the field of automation and process control. It enables the control of continuous processes using PLCs and includes stations for temperature, level, flow, and pressure ...

SPECIFICATION

Purpose:

The training set is designed for the practical education of students in the field of automation and process control. It enables the control of continuous processes using PLCs and includes stations for temperature, level, flow, and pressure control.

General Requirements:

-

Compatibility of the offered equipment must be confirmed at the bidding stage.

-

The set must consist of 4 independently operable stations:

-

Temperature Control via PLC – 1 unit

-

Liquid Level Control via PLC – 1 unit

-

Flow Control via PLC – 1 unit

-

Pressure Control via PLC – 1 unit

-

-

Each station must be:

-

Fully assembled, commissioned, and operational

-

Available in regular production

-

Compatible with standard industrial 24 V DC PLCs

-

Supplied with all components for installation, operation, and instruction

-

Delivered with EC Declaration of Conformity

-

1. Temperature Control Station (Quantity: 1)

Function:

To measure and control temperature using a heater. Disturbances are introduced via a controllable fan. Temperature is measured by a Pt100 sensor with a transmitter.

Minimum Specifications:

-

Aluminum profile stand in “L” shape

-

Horizontal section for process model, vertical for PLC

-

Handle included for mounting table placement

-

Dimensions: 600–700 mm × 300–400 mm × 400–500 mm

-

-

24 V DC power supply

-

B10 A/30 mA residual current circuit breaker

-

Main power switch

-

Industrial PLC with:

-

≥14 digital inputs, ≥10 digital transistor outputs

-

≥2 analog 0–10 V inputs, ≥2 analog 4–20 mA outputs

-

Ethernet programming interface, PID functionality

-

Support for stepper motors, high-speed counters & outputs (≥2 × 100 kHz)

-

Expandability: ≥3 communication modules, 1 signal board, 8 I/O modules

-

-

Ethernet cable (min. 1.5 m)

-

PLC software:

-

Educational license (single user)

-

Built-in simulator

-

Programming languages: LD, FBD, SCL

-

-

HMI panel: Touchscreen ≥4", TH-35 rail mount

-

Heater Module (resistance type)

-

Pt100 sensor with analog transmitter

-

Dial thermometer

-

24 V DC fan module

-

Test object model: Aluminum block with aluminum casing

-

Control lights & buttons: Mounted on TH-35 rail

-

Start/Stop button (illuminated)

-

Yellow indicator button (illuminated)

-

Emergency stop (mushroom type)

-

≥3 bistable control buttons

-

-

All connecting/construction elements

-

Teaching materials (Polish):

-

User manual

-

Set of practical exercises

-

-

Demonstration software with editable source code

-

PLC source code included with documentation

-

In-software job instructions

-

-

Power Supply: 230 V AC

-

EC Declaration of Conformity

2. Liquid Level Control Station (Quantity: 1)

Function:

To monitor and control the liquid level in a tank using a DC pump. Interferences can be introduced via a disruption drain valve.

Minimum Specifications:

Same structure and components as Temperature Station with the following specifics:

-

24 V DC water pump

-

Transparent tanks:

-

Measuring tank (cylindrical, min. 0.3 L)

-

Supply tank (min. 2 L, max. 3 L)

-

-

Industrial level sensor with analog output

-

Plastic piping system with elbows

-

Disruption drain valve

-

Control panel & safety equipment as previously described

-

All connecting/construction elements

-

Teaching materials (Polish):

-

User manual

-

Practical exercises

-

-

Teaching software with editable PLC code

-

Includes job instructions

-

-

Power Supply: 230 V AC

-

EC Declaration of Conformity

3. Liquid Flow Control Station (Quantity: 1)

Function:

To measure and control fluid flow using a DC pump and a vortex flowmeter. Disturbance is applied via a throttling valve.

Minimum Specifications:

Same general design as previous stations with:

-

24 V DC pump

-

Pump capacity controller

-

Throttling valve

-

Vortex flowmeter (analog output)

-

Rotameter

-

Transparent reservoir (2–3 L)

-

Pipeline model (plastic pipes and elbows)

-

Disruption valve

-

Control and indicator elements (buttons, lights)

-

Complete connection and assembly kit

-

Teaching materials (Polish):

-

User manual

-

Exercise set

-

-

Teaching software:

-

Editable PLC code

-

Documented source and job instructions

-

-

Power Supply: 230 V AC

-

EC Declaration of Conformity

4. Pressure Control Station (Quantity: 1)

Function:

To regulate air pressure in a tank using a proportional solenoid valve. Disturbance is introduced via a drain valve.

Minimum Specifications: Same general layout as above stations with:

-

Industrial pressure transmitter:

-

Electronic display, analog output (0–10 V or 4–20 mA)

-

-

Proportional solenoid valve with electronic controller

-

Pressure vessel:

-

Capacity: min. 1 L

-

Operating range: 0–11 bar

-

-

Drain valve (for introducing disturbance)

-

Control lights and switches as above

-

Complete set of construction and wiring accessories

-

Teaching materials (Polish):

-

User guide

-

Practical exercise set

-

-

Educational demonstration software:

-

Editable and documented PLC code

-

Instruction integrated in software

-

-

Power Supply: 230 V AC

-

EC Declaration of Conformity

91-9829132777

91-9829132777