Study of Thermoluminescence of F-centres in Alkali Halide Crystals

Order Code: 55536

Category: Physics Trainers

Pure alkali halide crystals are transparent throughout the visible region of the spectrum. The crystals may be colored in a number of ways by the introduction of chemical impurities by introducing an excess of the metal ion by X-ray, g-ray,...

SPECIFICATION

Pure alkali halide crystals are transparent throughout the visible region of the spectrum. The crystals may be colored in a number of ways

- by the introduction of chemical impurities

- by introducing an excess of the metal ion

- by X-ray, g-ray, neutron and electron bombardment

- by electrolysis

A colour centre is a lattice defect that absorbs visible light. The simplest colour center is an F-centre. The name comes from the German word for colour, Forbs. We usually produce F-centres by heating the crystal in excess alkali vapours or by irradiation. The new crystals show an absorption band in the visible or ultraviolet, whereas the original crystals are transparent in that region. This absorption band is called F-band.

An F-centre can be regarded as a negative ion vacancy and an electron which is equally shared by the positive ions, surrounding the vacant lattice site. Conversely a hole may be trapped at a ve ion vacancy or at a -ve ion, giving rise to V- and H-centres respectively.

Colour centres produced by irradiation with X-rays

When a X-ray quantum passes through an ionic crystal, it will usually give rise to a fast photo-electron with an energy of the same order as that of the incident quantum. Such electrons, because of their small mass, do not have sufficient momentum to displace ions and therefore loose their energy in producing free electrons, holes, excitons and phonons. Evidently these while moving near the vacancies form trapped electrons as well as trapped holes.

The trapped-electron or trapped-hole centres so formed can be destroyed (bleached) by illuminating the crystal with light of the appropriate wavelength or warming it.

Thermoluminescence

Important information about the colour centres can be obtained by measuring the changes that occur when a coloured crystal is gradually heated. As the temperature is raised electrons and holes escape from their traps at an increasing rate. The freed charges can recombine with each other or with other defects and give out luminescence by recombination. The resulting thermoluminescence or ‘glow’ reaches maximum and then decreases to zero as the supply of trapped electrons or holes becomes exhausted. The plot of luminescence intensity verses temperature, taken at a constant heating rate, is called the ‘glow curve’. It may contain one or many glow peaks, depending upon whether there are one or several different kinds of traps.

From the glow curve one determine the trap depth; the deeper the trap, the higher the temperature of the glow peak. A correlation between the temperature at which thermoluminesce nce occurs and the temperature at which particular band bleach can give valuable information about specific centres.

Typical results obtained from this set-up for KCl crystal are shown in figure.

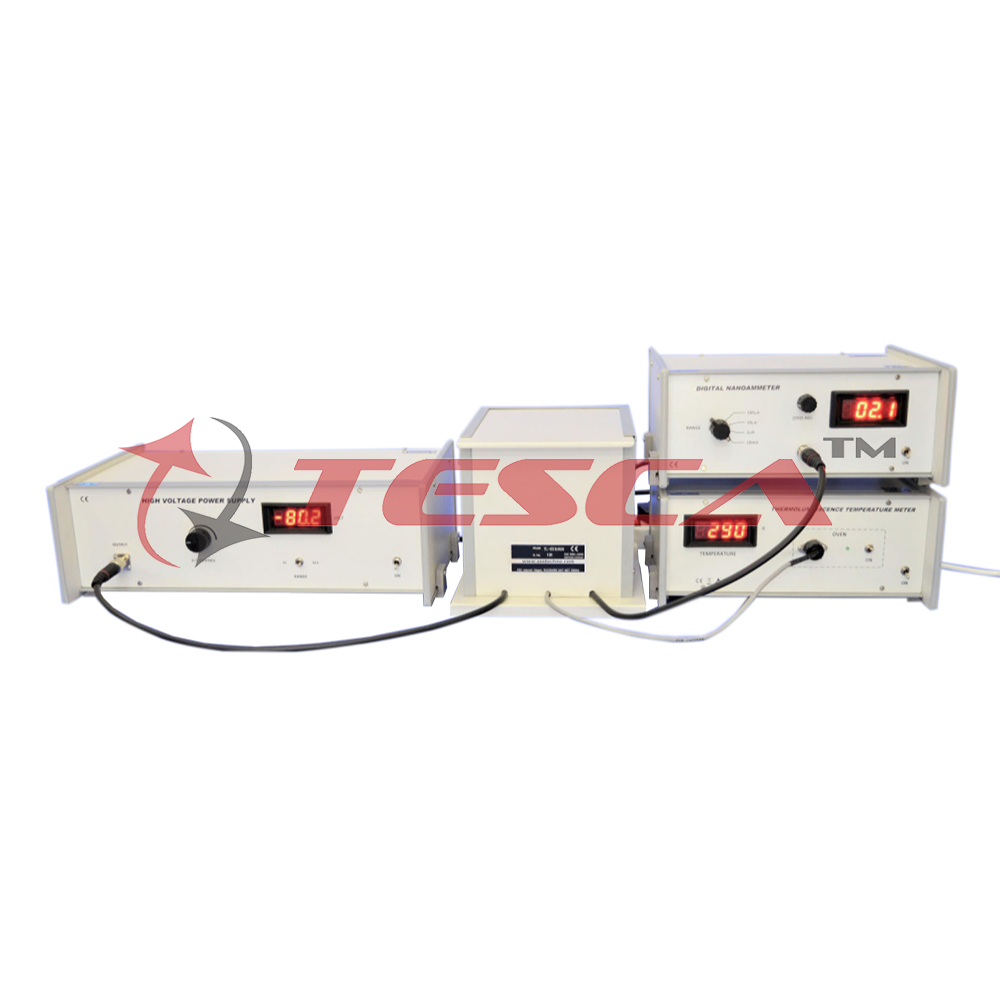

The experiment consists of the following

Experimental set-up for creating thermoluminescence

- Sample: KBr or KCl single crystal

- Thermolumniscence Temperature Meter

- Digital Thermometer

- Oven Power Supply

- Sample Holder

- Thermoluniscence Oven (0-423K)

- Black Box

For measurement of luminescence intensity

- Photomultiplier tube: R11558

- PMT Housing with biasing circuit and coaxial cables etc.

- High Voltage Power Supply, Model: EHT-11

- Output : 0-1500V variable (1mA max.)

- Regulation : 0.05%

- Display : 3½ digit 7-segment LED

- Nanoammeter, Model DNM-121

- Range : 100nA to 100mA full scale in 4 ranges

- Accuracy : 0.2%.

- Display : 3½ digit 7-segment LED

Photomultiplier Tube

Specifications of Photomultiplier tube

- Spectral Response

- Range : 300 to 650(nm)

- Peak wave length : 400nm

- Photo Cathode Material : Bialkali

- Dynode Structure/No. of Stages : CC/9

- Maximum Cathode Voltage : 1250Vdc

- Maximum Average Anode Current : 0.1mA

- Cathode Sensitivity

- Minimum : 40µA/lm

- Typical : 60µA/lm

- Anode Sensitivity

- Minimum : 200A/lm

- Typical : 600A/lm

- Anode to Cathode

- Supply Voltage : 1000Vdc

- Current Amplification : 1.0x107

- Anode Dark Current (after 30min)

- Typical : 1nA

- Maximum : 10nA

PMT Housing

The housing is designed to provide a shielding from stray light and magnetic field. The slit arrangement at the window is provide to adjust the size of the window according to the incident beam and for the safety of photomultiplier tube when not in use. For E.H.T. input and current output, amphenol connectors are provided. A general purpose biasing circuit, using low noise, metal film resistors, is mounted on the base. The housing can be mounted in any position.

The biasing circuit can be changed to customer’s specification. Minor modification in design of PMT Housing is also possible.

Thermolumniscence Irradiation unit 55537 can also be used for this purpose.

complete in all respect, only X-ray facilities required to create F-centers in the crystal.

91-9829132777

91-9829132777