|

Technical Specification and Standards

|

|

The system should contain the following training program:

|

- DC permanent magnets motor: general notions and mathematical modelization

|

- Electrical and mechanical characteristics

|

- Detection of the characteristics of the armature reaction of aDC motor

|

- Detection of the characteristics of an optoelectronic speed transducer

|

- Detection of the characteristics of a tacho-generator of industrial kind

|

- Detection of the characteristics of a potentiometric transducer of industrial kind

|

|

Study and calibration of the signal conditioners for:

|

|

|

|

|

- Optoelectronic transducer

|

- Potentiometric transducer

|

- Study of the response of Proportional, Integrative and Derivative controllers at different input signals

|

- Speed servomechanisms with DC motor

|

- Position servomechanism with DC motor

|

- DC/DC MOSFET converter for 4-quadrant operation

|

- Driver for the MOSFETs of the DC/DC converter

|

- PWM modulation for driving the DC/DC converter

|

- Process response using a controller with independent actions:

|

|

|

|

|

|

|

- Control of the maximum armature current;

|

- System response at variation of the braking load;

|

- Analysis and use of the supervision software with Personal Computer

|

|

Technical Specifications:

- Front panel in insulating material, with silk screen printed diagram of the different circuit blocks of the module and electrical diagram of each circuit;

|

|

Terminals for the connections and measurements;

|

- Tachymetric transducer should be fitted to the motor axis;

|

- Signal conditioner for matching the voltage levels;

|

- action. Characteristics of the speed and conditioner transducer:

|

- Speed input range: ±4000 r.p.m. or higher

|

- Output voltage range: ±8 V or higher

|

- Optoelectronic transducer;

|

- Signal conditioner with indication on 7-segment and at least 4-digit display of the rotation speed (r.p.m.);

|

- Potentiometric transducer;

|

- Signal conditioner for potentiometric transducer. Characteristics of the position and conditioner transducer

|

- Position input range: 0 – 360°

|

- Output voltage range: ±8 V or higher

|

- Reference voltage generator (Set-point) with integrated stabilizer

|

- 2 Error amplifiers for double loop controls (position + speed);

|

- 1 Rotary potentiometer for setting the speed and position setpoints;

|

- PID controller with P, I, D independent actions;

|

- 3 Potentiometers for independent setting of the P, I, and D parameters, with wide regulation margins;

|

- Limit circuit for the armature current;

|

- DC/DC converter, 4-MOSFET “H-bridge” configuration;

|

- 4 Drivers for the MOSFET;

|

- 8-pole DIN cable with socket for the connection to an external unit mod. TY36A/EV;

|

|

|

|

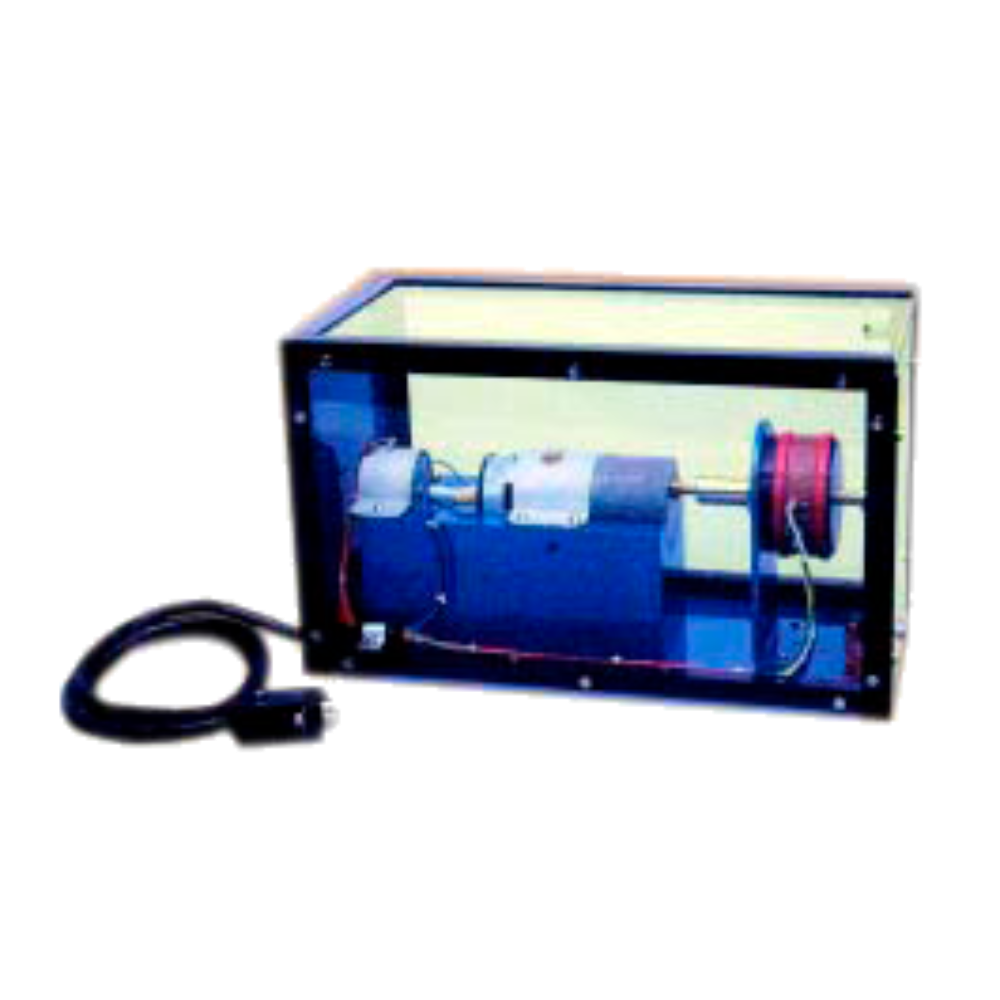

External Unit for Speed and Position: The external unit should be composed of:

|

|

|

- DC permanent magnet motor; Item No. Name of Item Technical Specification and Standards

|

- Epicycloidal planetary gearing;

|

- Tacho-generator fixed to the motor axis;

|

- Optoelectronic transmission sensor;

|

- Transparent and opaque disk for fork optoelectronic

|

|

|

- Potentiometric transducer;

|

- Angular position indicator for the angular position;

|

|

|

|

Characteristics of the DC permanent magnet motor should be:

|

- Rotation speed: 4000 RPM or higher

|

- Nominal voltage: 24 V or higher

|

- Armature resistance, Ra: 5.5 Ohm;

|

- Armature inductance La: 2.8 mH;

|

- Constructional form: B14;

|

- Permanent magnets: ferrites;

|

|

|

|

|

|

Power Supply Unit:

|

|

|

|

|

- The minimum supplied voltages should be:

|

|

|

|

|

|

|

- Output S4: +12 Vdc – 2A, -12 Vdc – 1A

|

- Output S5: 1.3 Vdc – 24 Vdc, 1A

|

- Output on DIN connector: 24 Vac – 0 – 24 Vac, 0.5A

|

- Power source: 230 Vac 50 Hz single-phase - 200 VA

|

- Dimensions: Minimum 415 x 185 x 195 mm

|

|

|

|

Box Module:

|

- Support for housing the experimental modules.

|

- Can be fixed to the frame by a “Plug-in” system.

|

|

Personal Computer Interface with Data Acquisition Software:

|

|

|

- 16 Single-ended / AD 12-bit converter

|

- Voltage range: ±10Vdc or higher

|

- Protection against over-voltages

|

|

|

- 2 Single-ended / AD 8-bit converter

|

- Voltage range: ±10Vdc ±1.5%

|

|

|

|

|

|

|

|

|

|

|

- USB-powered, current absorption < 100 mA, auto-calibration and initial auto-reset

|

- Maximum conversion frequency: 10 kHz or higher

|

|

|

|

|

- USB Driver, microcontroller firmware, DLL with API components for the development of interface software for specific applications.

|

|

Standard Accessories: The equipment / instrument which are required to carry out the required experiment should come under standard accessories. The following accessories should be supplied along with this equipment: o Storage case/box

|

|

Technical Specification and Standards

|

|

The system should contain the following training program:

|

- DC permanent magnets motor: general notions and mathematical modelization

|

- Electrical and mechanical characteristics

|

- Detection of the characteristics of the armature reaction of aDC motor

|

- Detection of the characteristics of an optoelectronic speed transducer

|

- Detection of the characteristics of a tacho-generator of industrial kind

|

- Detection of the characteristics of a potentiometric transducer of industrial kind

|

|

Study and calibration of the signal conditioners for:

|

|

|

|

|

- Optoelectronic transducer

|

- Potentiometric transducer

|

- Study of the response of Proportional, Integrative and Derivative controllers at different input signals

|

- Speed servomechanisms with DC motor

|

- Position servomechanism with DC motor

|

- DC/DC MOSFET converter for 4-quadrant operation

|

- Driver for the MOSFETs of the DC/DC converter

|

- PWM modulation for driving the DC/DC converter

|

- Process response using a controller with independent actions:

|

|

|

|

|

|

|

- Control of the maximum armature current;

|

- System response at variation of the braking load;

|

- Analysis and use of the supervision software with Personal Computer

|

|

Technical Specifications:

- Front panel in insulating material, with silk screen printed diagram of the different circuit blocks of the module and electrical diagram of each circuit;

|

|

Terminals for the connections and measurements;

|

- Tachymetric transducer should be fitted to the motor axis;

|

- Signal conditioner for matching the voltage levels;

|

- action. Characteristics of the speed and conditioner transducer:

|

- Speed input range: ±4000 r.p.m. or higher

|

- Output voltage range: ±8 V or higher

|

- Optoelectronic transducer;

|

- Signal conditioner with indication on 7-segment and at least 4-digit display of the rotation speed (r.p.m.);

|

- Potentiometric transducer;

|

91-9829132777

91-9829132777