Resistivity of Semiconductors by Four Probe Method at Different Temperatures and Determination of the Band-gap (Basic Model)

Order Code: 55531

Category: Physics Trainers

The Four Probe Method is one of the standard and most widely used method for the measurement of resistivity of semiconductors. The experimental arrangement is illustrated. In its useful form, the four probes are collinear. The error due to contact re...

SPECIFICATION

The Four Probe Method is one of the standard and most widely used method for the measurement of resistivity of semiconductors. The experimental arrangement is illustrated. In its useful form, the four probes are collinear. The error due to contact resistance, which is specially serious in the electrical measurement on semiconductors, is avoided by the use of two extra contacts (probes) between the current contacts. In this arrangement the contact resistance may all be high compare to the sample resistance, but as long as the resistance of the sample and contact resistances are small compared with the effective resistance of the voltage measuring device (potentiometer, electrometer or electronic voltmeter), the measured value will remain unaffected. Because of pressure contacts, the arrangement is also specially useful for quick measurement on different samples or sampling different parts of the same sample.

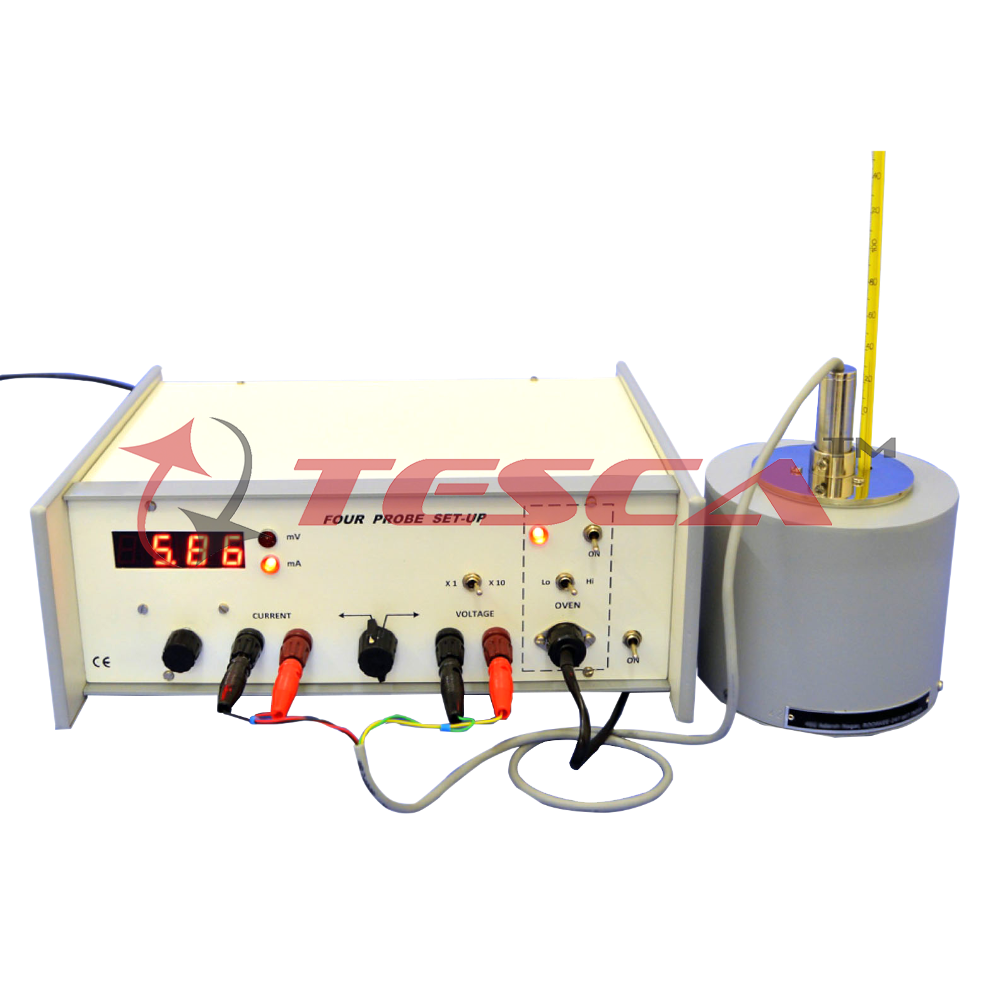

Description of the experimental set-up

- Probes Arrangement

- It has four individually spring loaded probes. The probes are collinear and equally spaced. The probes are mounted in a teflon bush, which ensure a good electrical insulation between the probes. A teflon spacer near the tips is also provided to keep the probes at equal distance. The whole - arrangement is mounted on a suitable stand and leads are provided for the voltage measurement.

- Sample

- Germanium crystal in the form of a chip (10X9X0.5mm)

- Oven

- It is a small oven for the variation of temperature of the crystal from the room temperature to about 200°C (max.)

- Four Probe Set-up, 55531

- The set-up consists of three units in the same cabinet.

(i) Multirange Digital Voltmeter

In this unit, intersil 3½ digit single chip A/D Converter ICL 7107 has been used. It has high accuracy like auto zero to less than 10μV, zero drift of less than 1μV/ °C, input bias current of 10pA max. and roll-over error of less than one count. Since the use of internal reference causes the degradation in performance due to internal heating, an external reference has been used.

Specifications

- Range : X1 (0-200mV) & X10 (0-2V)

- Impedance : MW

- Resolution : 100μV at X1 range

- Display : 3½ digit, 7 segment LED (12.5mm height) with polarity and decimal indication

- Accuracy : ±0.1% of reading ±1 digit

- Overload Indicator : Sign of 1 on the left & blanking of other digits

(ii) Constant Current Generator

It is an IC regulated current generator to provide a constant current to the outer probes irrespective of the changing resistance of the sample due to change in temperatures. The basic scheme is to use the feedback principle to limit the load current of the supply to preset maximum value Variations in the current are achieved by a potentiometer included for that purpose. The supply a highly regulated and practically ripple free d.c. source. The current is measured by the digital panel meter.

Specifications

- Open Circuit Voltage : 18V

- Current range : 0-20mA

- Resolution : 10μA

- Accuracy : ±0.25% of the reading ±1 digit

- Load regulation : 0.03% for 0 to full load

- Line Regulation : 0.05% for 10% changes

(iii) Oven Power Supply Suitable voltage for the oven is obtained through a step down transformer with a provision for low and high rates of heating. A glowing LED indicates, when the oven power supply is ‘ON’.

91-9829132777

91-9829132777