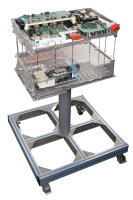

Pure Electric Vehicle Chassis System Trainer

Order Code: NEE65

Category: New Energy Equipments

Product Introduction The comprehensive chassis training equipment for pure electric vehicles adopts the BYD E5 pure electric vehicle with the body shell removed, retaining the original vehicle chassis power and other systems, including complete ch...

SPECIFICATION

Product Introduction

The comprehensive chassis training equipment for pure electric vehicles adopts the BYD E5 pure electric vehicle with the body shell removed, retaining the original vehicle chassis power and other systems, including complete chassis power and other system component, it fully demonstrator the internally and externally structure of each system of the car, and all system components are complete. , cut open and remove the car smell, you can clearly observe the movement of the car's internal structure and components and car complete chassis system can actually operate. It is suitable for teaching needs of pure electrical vehicle construction theory and maintenance practice.

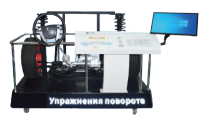

Functional Characteristics

1. The complete chassis system of a real pure electric vehicle can actually aperate.

2. The movement process of each main component can be clearly seen, and each system is painted in different colors for easy distinction.

3. Ability to teach pure electric chassis structure, basic working principles, disassembly, assembly and maintenance.

4. The chassis system is fully configured (including steering system, braking system, front and rear axles and wheels, motor drive system, motor control unit, battery pack, driver sheet steering system etc.)

5. The lighting, instrumentation, electrical appliances, and air-conditioning systems are complete and operational

6. During the testing and training, the chassis system training platform can operate under normal road driving conditions.

7 Install a fault simulation system to realize fault setting and diagnosis and elimination of low-voltage circuit systems, It can set the settings of common faults and assess fault points 24

8. Supporting teaching materials such as practical training (experiment) instructions, including working principles, practical training projects, fault settings and analysis and other key points.

9. Install safety protection devices: emergency stop switch, mechanical main power switch, maintenance switch, protective cover for rotating parts, high-voltage safety protection devices and warming prompts

Technical Specifications

- Working power supply: original vehicle

- Working temperature :-50°C ~ +50°C

- Car chassis: length*width*height: 4730*1700*1400mm

- Inspection table moving casters: 100*60mm

91-9829132777

91-9829132777