Pressure Control Valves

Order Code: LFC™_1B

Category: Range of Medium to High Pressure Valves

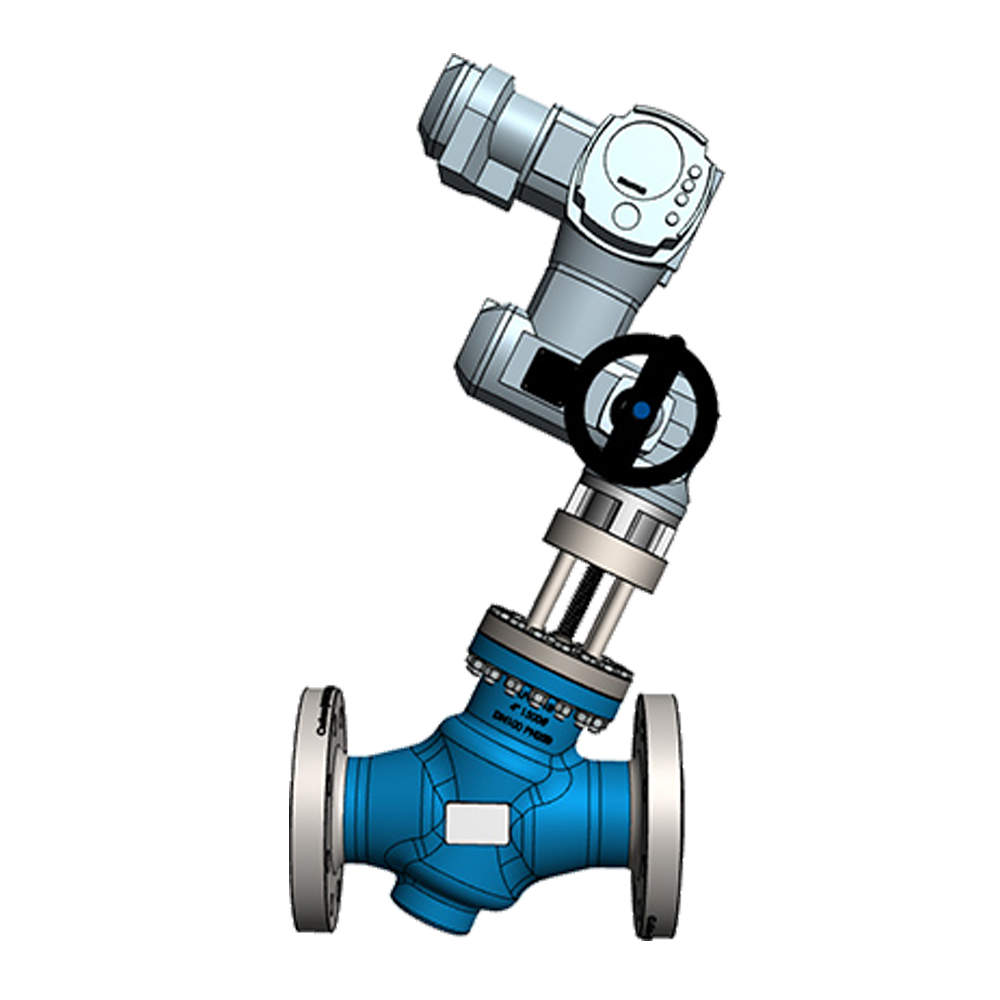

OVERVIEW A pressure control valve is designed to maintain a desired downstream pressure irrespective of the flow requirement. The LFC™_1B pressure control valve is fitted with a modulating intelligent electrical actuator. Any make of electri...

SPECIFICATION

OVERVIEW

A pressure control valve is designed to maintain a desired downstream pressure irrespective of the flow requirement. The LFC™_1B pressure control valve is fitted with a modulating intelligent electrical actuator. Any make of electrical actuator can be fitted to the pressure control valve. The LFC™_1B pressure control valve has been developed to present a robust and simple solution to fluid handling issues in any industrial sector.

SIMPLICITY

The LFC™ pressure control valve is designed to offer increased efficiency and accuracy as well as improve on ease of maintenance and in effect only has one moving part called the plug. The plug is a piston that is engineered to be balanced. The balanced plug enables easy opening and closing at any pressure and differential condition. The differential pressures do not affect the operating torque which results in a relatively flat torque curve allowing for the fitment of smaller actuators.

FEATURES

- Reduced cavitation

- Low noise levels

- Low vibration

- One moving part

- Increased flow capacity

- Long lasting

ROBUST, RELIABLE & EFFICIENT

Due to the minimal number of moving parts to effect the fluid control, the number of potential failures are minimized.

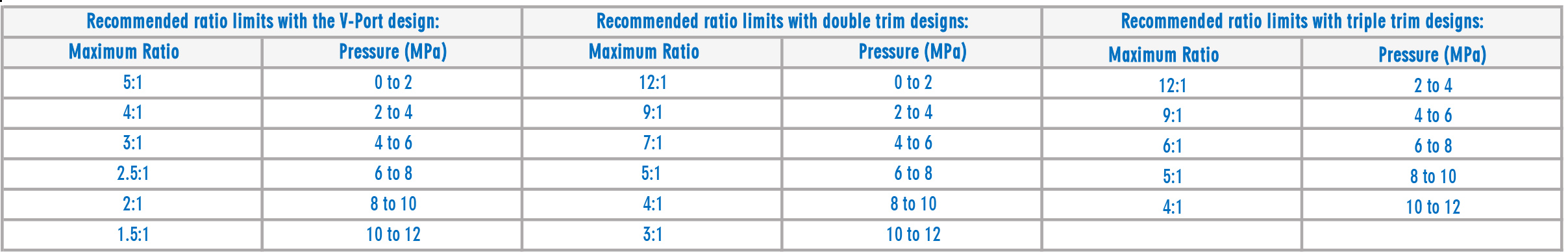

SELECTING CONTROL VALVE WITH TRIM DESIGN

Note! Only in cases where the water / fluid is free from large particles, control valves with trims can be considered. Should there be particles present in the fluid where a trim design control valve was selected, the trim will act as a strainer. Besides potentially impacting the pressure losses across the valve, this can also result in mechanical interference with the plug travel and stop the valve from operating.

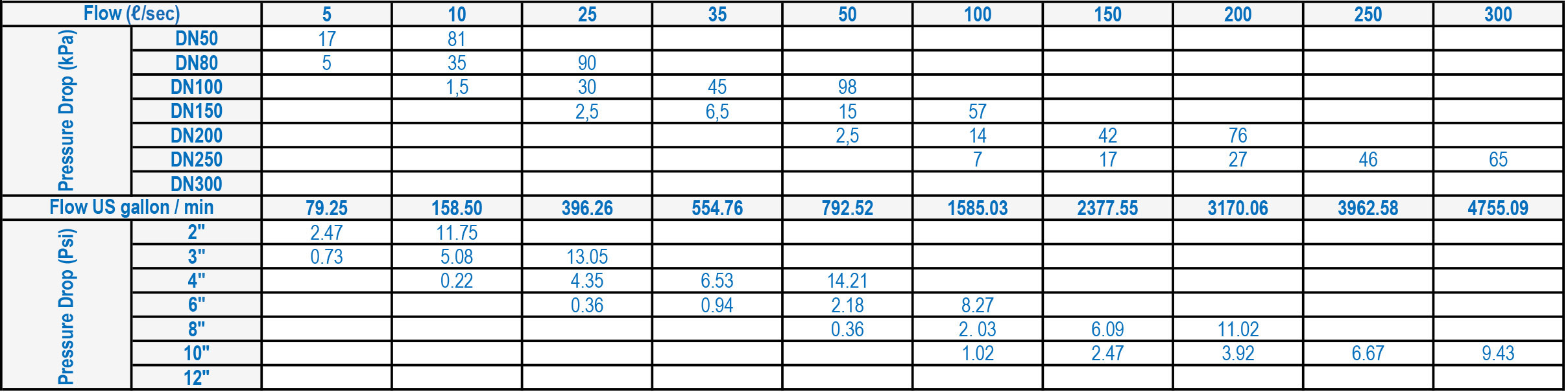

FLOW RATES

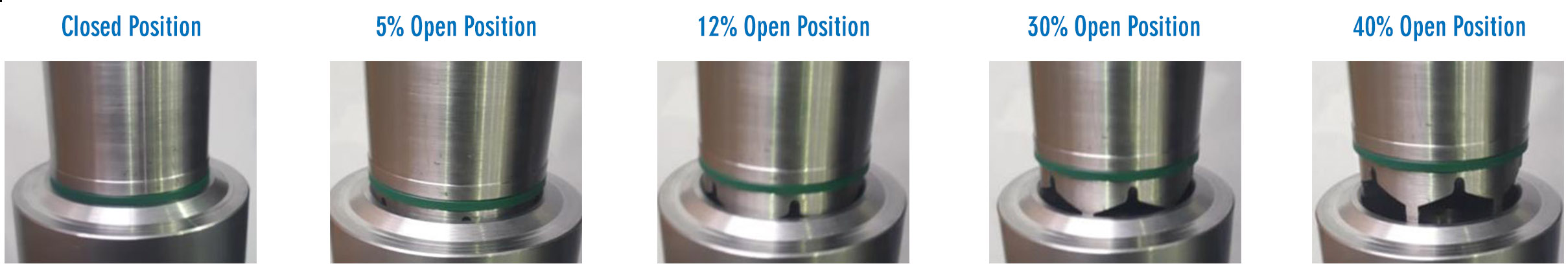

PLUG ASSEMBLY, V-PORT AND DEALING WITH CAVITATION

As displayed, the LFC™_1B pressure control valve plug assembly and movements.

Closed Position: Shows the plug assembly on the body seat in a fully closed valve position.

5% Open Position: Shows the plug assemble in a 5% open position. It can clearly be seen that only the top of the V-Port opens up and creates a flow path. This reduces cavitation and helps with fine control at low flow conditions.

12% Open Position: Shows the plug assembly in the 12% open position. Now it can be observed how the V-Port moved away from the seat and the openings are increasing proportionally. At this point the top of the V-Ports are now being exposed to the flow path.

30% Open Position: Shows the plug assembly in the 30% opened position. Now it can clearly be seen that the full V-Port is creating a larger orifice in the flow path. Up to this point, cavitation needs to be dealt with to increase the life expectancy of the valve. The V-port trim ensures that the seating elements are further apart from each other during low flow allowing the cavitation to take place on noncritical components of the valve.

40% Open Position: Shows the plug assembly in the 40% open position. Now it can clearly be seen that the V-Port is completely away from the seat and the flow path is now relatively large. At this point the flow is approaching its medium demand flow rate and the V-Port has little to no function.

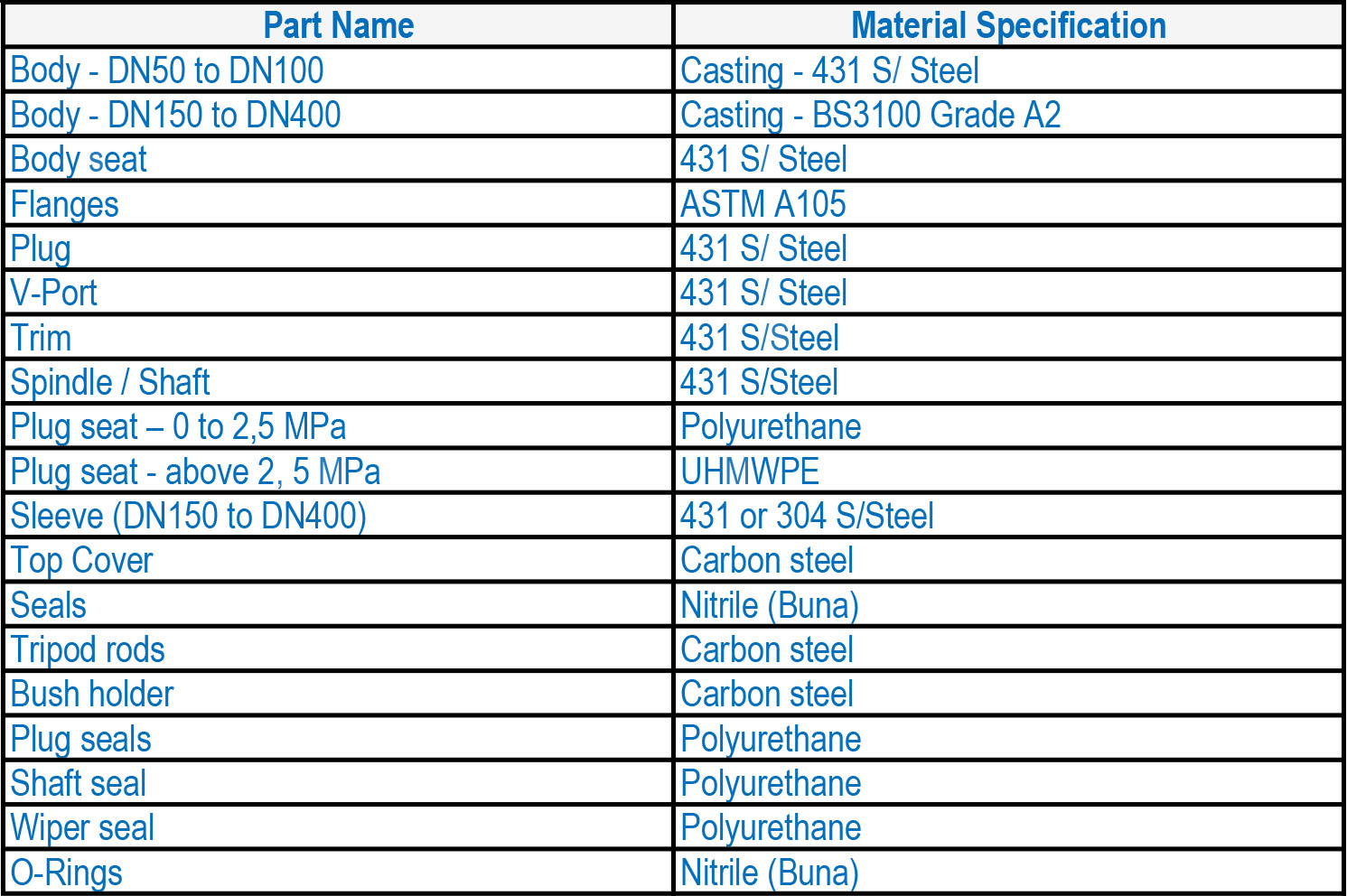

MATERIALS OF CONSTRUCTION

LOW MAINTENANCE REQUIREMENT

All the moving parts of LFC™_1B pressure control valve are manufactured from stainless steel which increases reliability and durability. The LFC™_1B pressure control valve requires minimal maintenance, the majority of which, can be conducted with the valve remaining in situ.

ROBUST, RELIABLE AND EFFICIENT

Due to the minimal number of moving parts to effect the fluid control, the number of potential failures are minimized. The valve can only fail for the following reasons:

1. Lack of maintenance: If filters are utilized in the control system, regular cleaning of the filters are required to prevent the valve operation from slowing down and eventu ally creating a possible hydraulic locking of the valve. This process depends on the condition of the service water being used. The dirtier the water, the shorter the filter maintenance intervals will need to be. A valve seal replacement program should be employed to ensure that the valves plug seals are replaced in accordance with manu facturer 's recommendations. As these seals are largely protected the intervals for maintenance on these items can usually be done in terms of years. If these seals fail, the valve will start to bypass pressure from the Pu to the air vent chamber. Valves are equipped with tell-tale breather holes which will immediately indicate seal failure .

2. Mechanical fouling: Should a large object be introduced into the service water piping and reach the valve inlet, such object could create a mechanical jam and prevent the plug from operating.

3. Overriding of the control system: As the valve is hydraulically actuated and controlled, if the control system is isolated from the service water by way of isolation valves in the control system, the valve will be hydraulically locked in position and will be unable to adjust to the inline condition changes .

4. Mechanical failure of the main seating arrangement: In time, the seating arrangement will experience conditions of high velocity across the seating surface during low flow conditions. The high velocity will eventually cause wear on the seating surface and on the plug seating surface. If the valves starts to bypass across its seat, the down stream pressure could increase to the point where the pressure relief valve is activated during low flow conditions.

All of these conditions are easily avoidable and rectifiable through regular maintenance programs and service water quality control and condition monitoring.

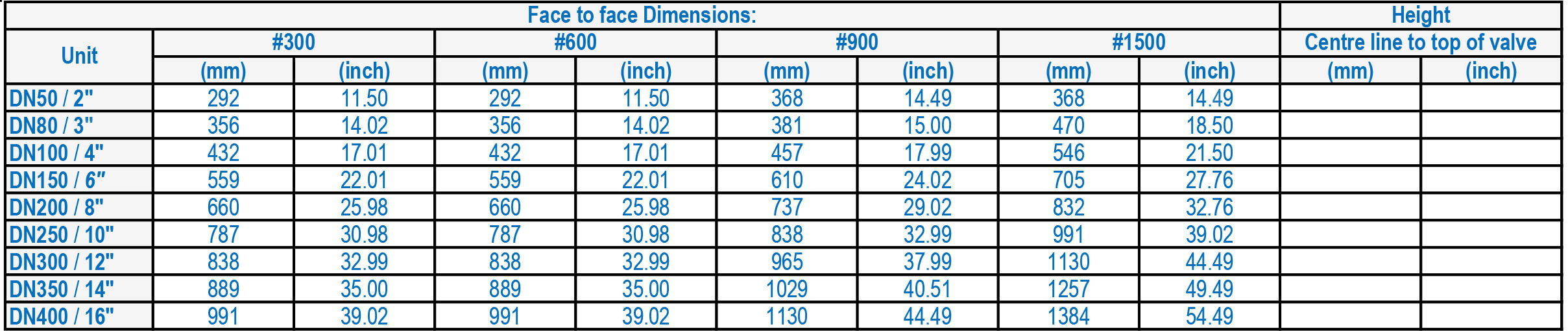

DIMENSIONS

VALVE DESIGN

Please consult with Hydromine for clarification of correct sizing for your requirements.

DESIGN AND MANUFACTURING STANDARDS

The LFC™_1B Pressure control valve has been designed in accordance with various international standards as set out below:

ASME Boilers and pressure vessels design code

ANSI B16.10 ANSI B16.3

ANSI B16.34 ANSI B16.37

ANSI B16.5 ANSI N278 .1

Available sizes: DN50 / 2" to DN400 / 16"

Face to face dimensions to ANSI B16.10

Pressure rating: up to 25MPa / 3 626 Psi

Available end connections: ANSI B16.5, BS4504, BS10, AS/NZS 4331.1 (ISO 7005-1) DIN, All makes of grooved or ring joint couplings, HMP™ Couplings, HMP™-TE tapered couplings and other as per clients requirement.

91-9829132777

91-9829132777