Portable Pneumatic Troubleshooting Learning System

Order Code: 24258098.103

Category: General Lab Equipment V

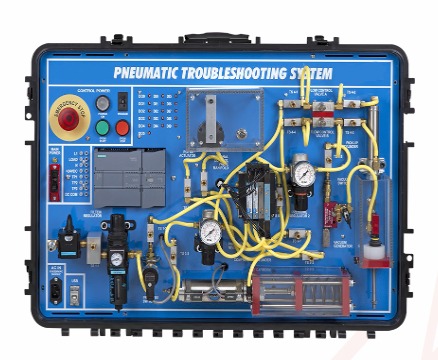

Portable Pneumatic Troubleshooting Learning System Portable Pneumatics Troubleshooting Learning System (990-PTB1) teaches a variety of hands-on pneumatic troubleshooting skills that are vital for those who will perform industrial maintenance, inst...

SPECIFICATION

- Portable Pneumatic Troubleshooting Learning System Portable Pneumatics Troubleshooting Learning System (990-PTB1) teaches a variety of hands-on pneumatic troubleshooting skills that are vital for those who will perform industrial maintenance, installation, and troubleshooting on pneumatic systems used in real-world automation machinery, packaging equipment, pharmaceutical applications, and chemical handling tasks.

- The system features real-world components, such as valves, switches, and gauges — all within a convenient, durable, portable learning system.Some of the portable pneumatic troubleshooting training system’s industry-standard components include directional control valves, flow control valves, limit switches, and a programmable logic controller.

- The system also features exclusive electronic fault insertion software.

- Using these real world components, learners will study a wide variety of pneumatic troubleshooting topics, such as air preparation, pneumatic actuators and valves, vacuum systems, and pneumatic systems.

- (i) Practice Hands-On Pneumatics Troubleshooting with Real World Components The portable pneumatic troubleshooting training system features real-world components learners will encounter on the job, including directional control valves, double acting cylinders, flow control valves, vacuum and pressure gauges, and a S71200 Siemens PLC — all within a convenient, durable, portable learning system. Learners will learn hands-on skills, such as troubleshooting filters, cylinders, flow control valves, and quick exhaust valves via an in-circuit test. Learners will also practice troubleshooting low pressure, high pressure, actuators that move out of sequence, and actuator speed.

- (ii) Curriculum Features Engaging, Highly-Interactive Multimedia’s curriculum features a highly-interactive, multimedia format that includes stunning 3D graphics and videos, voiceovers of all text, and interactive quizzes and exercises designed to appeal to learners with different learning styles. The pneumatic troubleshooting curriculum teaches learners a variety of pneumatic troubleshooting topics, including symptoms of lubricator failure, the function of a rotary actuator, symptoms of vacuum switch failure, and how to troubleshoot zero pressure.

- (iii) Practice Realistic Pneumatics Troubleshooting with Fault insertion The portable pneumatic troubleshooting training system features electronic fault insertion system which allows users to insert more than 30 faults into the system for realistic troubleshooting of situations they will encounter on the job. computer-based faults automatically track progress, enabling learners to gain troubleshooting skills in a self-paced environment that ensures that faults are inserted safely, protecting both learners and equipment. Basic Hydraulic Troubleshooting Learning System Basic Hydraulic Troubleshooting Learning System teaches learners how to troubleshoot hydraulic systems and their components, such as hydraulic motors, directional control valves, and cylinders. The system combines comprehensive curriculum with real-world equipment to create a valuable

- learning experience for maintenance technicians across a wide variety of industries. It also provides a strong foundation for those seeking important industry-standard certifications.This troubleshooting training system features over 35 faults for learners to practice troubleshooting hydraulic pumps, actuators, valves, and systems, as well as directional control valves. The system includes durable, industry-standard components, such

- as a Siemens S71200 PLC, a hydraulic power unit, a flow meter, a pressure gauge, and hydraulic actuator branches.

- (i) Master Basic Troubleshooting Skills with Real-World Components

- The hydraulic troubleshooting system features a large array of industrial-grade components on a mobile workstation, including a Siemens S71200 PLC with HMI, a hydraulic power supply, supply and return lines, motor with flywheel, proximity switches, magnetic reed sensors, and a wide variety of valves. Learners will use these real-world components to practice hands-on troubleshooting skills they will use on the job. Some of these skills include using an in-circuit test to troubleshoot a fixed-displacement pump, adjusting a cylinder cushion, troubleshooting a check valve, testing a hydraulic system by measuring fluid flow, and troubleshooting vibration in a hydraulic system.

- (ii) Get Hands-On Practice Troubleshooting Over 35 Faults on Valves, Pumps, and Motors The hydraulic troubleshooting system features over 35 manually inserted faults to help learners understand and practice troubleshooting common problems found in hydraulic systems. Sample faults include: motor starter failure, defective pump, worn cylinder seals, blocked flow control valves, and blocked inlet ports.

- (iii) Engaging, Highly-Interactive Multimedia The training curriculum features interactive multimedia that includes stunning 3D graphics and videos, voiceovers of all text, and interactive quizzes and exercises designed to appeal to learners with different learning styles. For example, the curriculum takes a comprehensive approach to hydraulic troubleshooting, covering both component-level faults and

- system-wide problems. Users will learn about a wide variety of topics, including pressure test points, flow measurement, cavitation and pseudo-cavitation, and troubleshooting hydraulic pumps, cylinders, motors, valves, and systems.

91-9829132777

91-9829132777