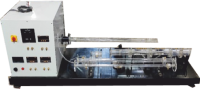

Pipe Friction Apparatus

Order Code: 32024

Category: Fluid Mechanics Lab

Study of pipe friction and hence the pressure loss in pipes is important in view of the pumping power requirements in any pipe system. Tesca Pipe Friction Apparatus is an experimental setup necessary for any Fluid Mechanics and Hydraulics Laboratory ...

SPECIFICATION

Study of pipe friction and hence the pressure loss in pipes is important in view of the pumping power requirements in any pipe system. Tesca Pipe Friction Apparatus is an experimental setup necessary for any Fluid Mechanics and Hydraulics Laboratory of an educational institution.

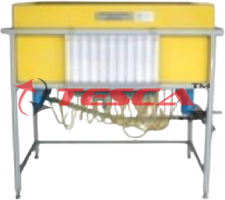

Tesca Pipe Friction Apparatus has been designed to enable students to determine the friction factor in the pipe flow and to study the effect of change in flow velocity on pipe friction. The Laminar and turbulent flow regimes can be obtained by varying the flow velocity and hence the flow Reynolds number. The apparatus consists of a horizontal test pipe with static pressure tapings at the upstream and downstream ends to measure head loss due to friction to determine the friction factor. Extra pipe lengths are provided at the inlet and exit to allow the flow to become fully developed and to damp out the flow disturbance originating from the valves and fittings. The test pipe is mounted on a support frame and there is a provision for leveling. Water is supplied from the hydraulic bench (for higher flow rates) and the constant head feeding tank (for lower flow rates). Pressure drop along the test pipe length is measured using the U-tube mercury manometer or the pressurized water manometer depending upon the flow velocity. These manometers are mounted on a display panel with calibrated scales.

The flow rate and hence the velocity though the test pipe is controlled by a regulation valve at the exit and the flow rate is measured by the flow meter or the measuring tank of the hydraulic bench. The friction factor is determined from the measured pressure loss and flow velocity. Experiments can be conducted at various flow velocities or Reynolds numbers to obtain friction factors in laminar or turbulent flow regimes. The complete unit is manufactured from corrosion resistant materials. The 32096 Hydraulic Bench or any other standard hydraulic bench models can be used to supply water.

Computer Based Learning Software is included to enable students to understand and conduct experiments, tabulate results and plot graphs.

The Tesca Pipe Friction Apparatus Demonstration Apparatus is an important experimental set-up for any Fluid Mechanics and Hydraulics Laboratory of an educational institution.

List of Experiments:

1. Familiarization with pressure measurements and the working of U-tube manometer.

2. Study of loss of head due to friction in a circular pipe at various mean flow velocities.

3. Study of friction factors in laminar and turbulent flow regimes.

4. Demonstration of the law of pipe friction resistance in laminar to turbulent flow regimes.

5. Establishment of critical Reynolds number.

6. Comparison of experimental results of friction factor – Reynolds number relationship with the well known Moody’s diagram.

Important Features and Specifications:

1. Test pipe, stainless steel, 3mm bore, 650mm long with two static pressure taps at 500mm apart.

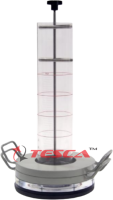

2. Feeding tank, capacity: 10 liters, constant water head: 600mm length & 140mm diameter ID.

3. Mercury U-tube manometer, range: 200mm.

4. Pressurized water manometer, range: 400mm WC.

5. Flow meter, range: 2 Lpm with needle valve to regulate flow rate.

6. Ancillaries include measuring cylinder (5 liter capacity), hand pump and a sample of test pipe (100mm long).

7. Portable digital manometer (Optional)

Options:

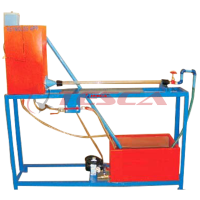

1. A self contained unit of the Pipe Friction Apparatus mounted on a mobile platform and with a flow controlled closed circuit water circulation unit consisting of centrifugal pump, flow meter, corrosion resistant sheet metal measuring tank and a sump tank will be supplied on request.

2. A digital pressure meter can be supplied as an alternative to the mercury U-tube manometer on request.

Services Required:

1. Water supply.

2. Electrical supply, 240 V, single-phase, 50 Hz.

Overall Dimensions:

Height: 1.2m, Width: 0.4m, Length: 0.9m.

The manual describing the theoretical and practical aspects of the apparatus, operation, analysis of results, and sample of results will be supplied with the equipment.

91-9829132777

91-9829132777