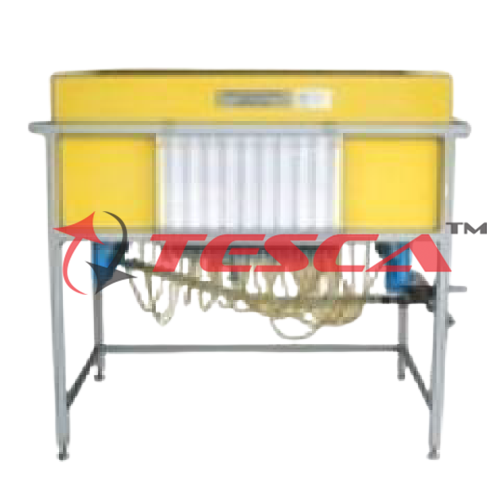

Permeability Tank Apparatusaratus

Order Code: 32045

Category: Fluid Mechanics Lab

Features: Two-dimensional permeability tank Stainless steel mesh end baffles Independently adjustable supply and drain header Models of impermeable sheet piling and foundation slab Permeable dam toe-filter Fourteen pressure tappings...

SPECIFICATION

Features:

Two-dimensional permeability tank

Stainless steel mesh end baffles

Independently adjustable supply and drain header

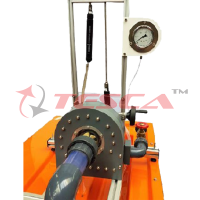

Models of impermeable sheet piling and foundation slab

Permeable dam toe-filter

Fourteen pressure tappings and multitube manometer

Dye injection system for tracing flow patterns and activated carbon de-colorizing filter

Scratch-resistant toughened glass front and rear sides

Optional computer interface with software!

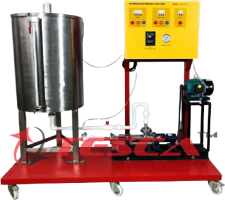

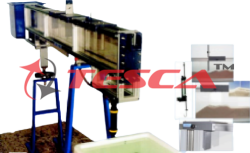

Tesca Permeability Tank Apparatus is mounted on a fabricated steel frame fitted with castors and leveling feet. The front, back, and ends of the tank are of clear toughened glass giving scratch-free visibility without the risk of abrasion of the inner surfaces by the permeable medium. The base of the tank incorporates fourteen pressure tappings at 100 mm pitch, the tappings are specially designed to prevent the ingress of sand particles. Flexible tubes connect the tappings to a 14 tube multi-tube manometer bank scaled 0 to 500 mm, for measurement of the water table height along with the tank. Removable end baffles are used to contain the permeable medium within the central part of the tank, thus providing inlet and outlet header compartments. A speed-controlled centrifugal pump circulates water from a sump tank to either or both of these header tanks. Adjustable overflow pipes in the header compartments allow the hydraulic gradient across the various models to be adjusted. An open-top enables easy access for setting up the experimental models and for filling the tank with the permeable material. A removable trap and sand chute are provided to allow convenient removal of the sand. Foundation model, sheet piling, and simulated dam models are manufactured from opaque PVC sheets and are fitted with seals that seal against the front and back of the tank. A dye injection system allows four dye lines to be generated which highlights visualization of flow lines and allows flow nets to be drawn for seepage analysis. Scales on the front panel assist in the preparation of models. An activated carbon decolorizing filter is provided in the sump tank to prevent the progressive dis-coloration of the water by prolonged use of dye. Scales on the front panel assist in the preparation of models and in the preparation and recording of flow nets. Washed silica sand graded 0.2 mm to 1.0 mm should be used as the permeable medium which must either be ordered separately or supplied by the end-user. Coarser material may also be used.

Specifications:

Framed glass tank, of internal dimensions 1900 mm long by 530 mm high and 130 mm front to back.

14 tube Manometer

Dye injection system made is transparent acrylic

Washed silica (Optional to be ordered)

Experiment Possibilities:

Confirmation of Darcy's Law and measurement of the Coefficient of Permeability

Draw down in two-dimensional horizontal flow

Two-dimensional drainage test

Flow through a permeable earth dam, with and without toe-filter

Seepage flow under an impermeable embankment or dam

Seepage flow under sheet piling and foundation slabs

Stability of slopes Demonstration of piping in the development of quicksand conditions

Construction of flow net diagrams

Distribution of uplift and lateral pressures on walls and structures

Services required:

Electrical

220/240V single phase 50Hz supply or

110/120V single phase 60Hz supply

Other voltages to special order

Water

Initial and periodic re-fill with cold water

Drain

Access to drain required for periodic emptying

Overall Dimensions:(Approximate and excluding permeable medium)

Length 2400 mm

Width 600 mm

Height 1800 mm

Weight 250 kgs

91-9829132777

91-9829132777