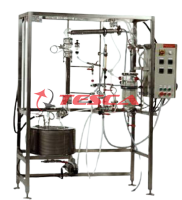

Packed Bed Distillation Column

Order Code: 32390

Category: Thermodynamics Lab

Features Stainless Steel tanks and wetted parts Superb Painted structure Simple to operate & maintain Compact & stand alone set up Packed Bed Distillation Column 32390 is made of Stainless Steel material packed with Borosilicate Glass ...

SPECIFICATION

Features

Stainless Steel tanks and wetted parts

Superb Painted structure

Simple to operate & maintain

Compact & stand alone set up

Packed Bed Distillation Column 32390 is made of Stainless Steel material packed with Borosilicate Glass rasching rings. An electrically heated reboiler is installed at the bottom of the column. The bottom product is collected in the tank. The vapours form the top of column are condensed in the shell and tube type condenser by circulating cooling water, supplied by laboratory overhead tank. The condensate is divided into reflux and distillate by automatic reflux divider and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is

provided for pressure & temp. measurement wherever necessary.

Specifications

Distillation Column: Material Stainless Steel, Dia 80mm, Length 900mm (approx).

Packing Material: Borosilicate Glass Rasching Rings.

Pressure Gauge: Bourdon type

Rotameter: For cooling water flow rate measurement.

Steam Generator: Made of Stainless Steel, provided with Pressure Gauge & Level Indicator, Safety valve & insulated with ceramic wool and cladding with Aluminum foil.

Reflux Divider: Special arrangement to change R/D ratio automatically.

Condenser: Shell & Tube type made of Stainless Steel.

Bottom Product Tank: Made of Stainless Steel, capacity 5 Ltrs.

Distillate tank: Made of Stainless Steel, capacity 5 Ltrs.

Heaters: Ni-Chrome wire heater.

Temp. Sensors: RTD PT-100 type (7 Nos)

Control panel comprises of:

Digital Temp. Controller: 0-199.9°C, (For Re-boiler)

Digital Temp. Indicator: 0-199.90C, with multi-channel switch With On/off switch, Mains Indicator etc.

Experiments

To estimate the batch distillation curves for a binary system and verify the binary batch distillation equation for a known packed height.

To operate the column under total reflux condition and estimate the HETP for the packing.

Required Services

Water Supply 2 LPM at 5 m head

Drain

Electricity Supply: 1Phase, 220 V AC, 6 kW

Required Chemicals

Refractrometer for analysis

91-9829132777

91-9829132777