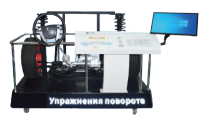

New Energy Vehicle Power Battery BMS Management and AC/DC Charging Teaching Platform

Order Code: NEE95

Category: New Energy Equipments

Product Functions The power battery pack testing training platform is based on new energy vehicle component and can perform power management system core component testing, single battery capacity classification, sorting, battery module assembly, s...

SPECIFICATION

Product Functions

The power battery pack testing training platform is based on new energy vehicle component and can perform power management system core component testing, single battery capacity classification, sorting, battery module assembly, system testing, function verification, etc. It meets the daily teaching needs for new energy vehicle power management system cognitive testing and diagnosis teaching and training.

Product Composition

The system consists of a lithium iron phosphate battery box, a battery management system (BMS battery management system includes a main board and a cluster board, an intelligent on-board charger (OBC), a DC/DC Conversion module, a charging relay, a total positive relay, a total negative relay a DC pre-charge relay a DC relay, a OC pre-charge resistor, a pre-charge relay, a precharge resistor, 2 Manual maintenance swatch (MSD), a Hall current sensor, an ignition switch, a touch screen, a WINDOWS host computer, a national standard mode 2 charging gun, a national standard AC charging seat, a national standard DC charging seat, 12V starting battery, and a detection panel It 5 equipped with a 43-inch touch all-in-one computer, an intelligent fault setting system, a smart detection terminal, and disassembly and assembly detection tools.

Teaching and Training Tasks

- Sorting of single cells

- Assembly of battery modules

- Power management system component inspection

- Battery management system

- Installation of maintenance switch

- Installation of onboard charger and charging socket

- Installation of high-voltage contactor

- Installation of current sensor

- Installation of BMS module

- Installation of DC/DC module

- Installation of pre-charge resistor and pre-charge contactor

Product Specifications

- Battery pack voltage : DC 76.8V

- High voltage contact specifications: Battery pack output 120A, charging and pre-charging 30A

- Working voltage: DC 12V

- Standard size: 1600*850*1700 (mm)

Product Requirements

The AC/DC charging intelligent platform needs to be equipped with national standard AC charging and OC charging modules, which can charge the training platform or system with AC or DC. And intelligent fault

setting system.

Teaching Takes

- Be able to judge the power of the charging pile according tothe nameplate or charging qun head-of the charging pile.

- Be able to master the internal structure of the AC charging pile and the connection status of each component.

- Be able to master the internal structure of the DC charging pile and the connection status of Each component.

- Be able to master the working principle of each component inside the AC charging pile and the role of each module.

- Master the working principle and control principle of the AC charging pile.

- Master the working principle and control principle of the DC charging pile.

- Be able to analyze common faults according to the changes in various data streams of the charging pile.

- Fault diagnosis and analysis of over voltage and undervoltage of the input of the AC charger.

- Fault diagnosis and analysis of over voltage and under voltage of the output of the AC charger.

- Fault diagnosis and analysis of poor communication of the AC meter.

- Fault diagnosis and analysis of poor communication of the DC meter.

- Fault diagnosis and analysis of poor communication of the AC and DC contactor.

- Fault diagnosis and analysis of poor communication of the AC and DC emergency control.

- Fault diagnosis of overheating of AC and OC charging.

- Be able to master the communication principle of AC and DC charging piles.

Product Specifications

- Equipment size: 7600*850*1700mm

- Equipment temperature: Working temperature: -20°~+40°

91-9829132777

91-9829132777