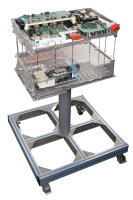

New Energy Vehicle Battery Pack Test Training Platform

Order Code: NEE90

Category: New Energy Equipments

Product Introduction Based on automobile parts, it can perform power management core component detection system, single cell capacity classification, sorting, battery module assembly, system assembly functional verification, etc., to meet the need...

SPECIFICATION

Product Introduction

Based on automobile parts, it can perform power management core component detection system, single cell capacity classification, sorting, battery module assembly, system assembly functional verification, etc., to meet the needs of cognitive testing and daily teaching and training. New energy vehicle power management system diagnosis.

Product Funtional Requirements

- Equipped with a special assembly and adjustment insulation workbench, parts assembly and line connection training of the power management system can be carried out on the insulation workbench.

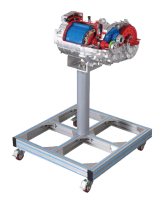

- The lithium iron phosphate power battery is equipped with a special base and connection terminals to meet the repeated disassembly and assembly training of the power battery. Using 6 single cells as a unit module, there are 4 modules in total.

- Using vehicle-grade maintenance switches, maintenance switch assembly and circuit wiring training can be carried out.

- The BMS management system adopts the national standard communication protocol to dynamically collect data such as 24-cell cell voltage and battery pack temperature in real time. It uses data bus, touch screen, and digital software to collect SOC value, cell voltage, charging capacity, discharge current, and power battery data. The total voltage, temperature and other data of the group are transmitted to the 10- inch multimedia terminal display, and the data can be displayed dynamically in real time.

- The internal resistance tester can be used to sort single cells, and the battery balancer can be used to perform balance training of single cells.

- Equipped with national standard charging interface and vehicle charging module, the charger can be installed and adjusted, After installation and debugging, the system can be charged through the charging pile.

- Equipped with charging and discharging high-valtage contactors, teaching and training on high-voltage contactor installation and wiring can be carried out.

- Equipped with OC/DC module, DC/DC module installation and wiring teaching and training can be carried out.

- Equipped with precharge resistor and precharge contactor, teaching and training of precharge circuit wiring can be carried out.

91-9829132777

91-9829132777