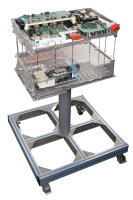

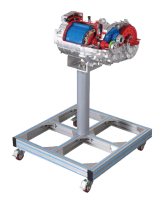

New Energy Modification Teaching Vehicle Supporting Vehicle Testing Training System

Order Code: NEE88

Category: New Energy Equipments

Product Introduction The product consists of a detection module, a manual setting module, a wireless fault collection system, a lossless jumper harness, a display system and the main frame of the bench; Supports two fault setting methods: manual f...

SPECIFICATION

Product Introduction

The product consists of a detection module, a manual setting module, a wireless fault collection system, a lossless jumper harness, a display system and the main frame of the bench; Supports two fault setting methods: manual fault setting and intelligent terminal wireless fault setting.

Technical Specifications

- The vehicle fault setting and detection connection platform is developed based on pure electric vehicles and designed according to the standard teaching concept of new energy vehicle fault diagnosis. It is a comprehensive teaching product including software and hardware systems to meet the technical fault diagnosis and practical training of new energy vehicles. need

- Configure the original adapter to achieve lossless and fast connection with the entire vehicle.

- Able to perform low-voltage power management of new energy vehicles such as body electrical module (BCM), battery management (BMS), motor control (PEU), air conditioning system module (thermal management), on-board charger (OBC), fast charging interface, and slow charging Interface, vehicle control unit (VCU), chassis management electronic handbrake control system, electronic power steering system and other system testing.

- On the detection panel, the socket measurement function completely follows the same pin arrangement and shape of the original car module and the wiring harness plug terminal, and multi-dimensional measurement is interactive in real time.

- It has wireless fault setting function, with a single fault point of no less than 100 channels.

- Fault settings such as line breakage, excessive line resistance (i.e, series resistance), line-to-positive grounding, line-to-graund grounding, and line channeling on a single component plug can be quickly performed on the back of the platform (the number of fault points is not less than 200 route)

Practical Tasks That can Be Practiced

Project 1: Routine maintenance of new energy vehicles

Task 1: The necessity of new eneray vehicle maintenance and car owners’ self-maintenance projects

Task 2: Routine maintenance projects in new energy vehicle stores

Project 2: Regular maintenance of new energy vehicles

Task 1: Maintenance cycles and contents of pure electric vehicles

Project 3: Fault diagnosis of new energy vehicles

Task 1: Operation and fault diagnosis process of new energy vehicle diagnostic equipment

Task 2: Troubleshooting high-voltage drive components

Task 3: New energy vehicle troubleshooting

Task 4: Troubleshooting of charging system

Task 5: Troubleshooting the battery management s

Task 6: Troubleshooting of vehicle controller

Task 7: Troubleshooting of vehicle electrical power distribution system

91-9829132777

91-9829132777