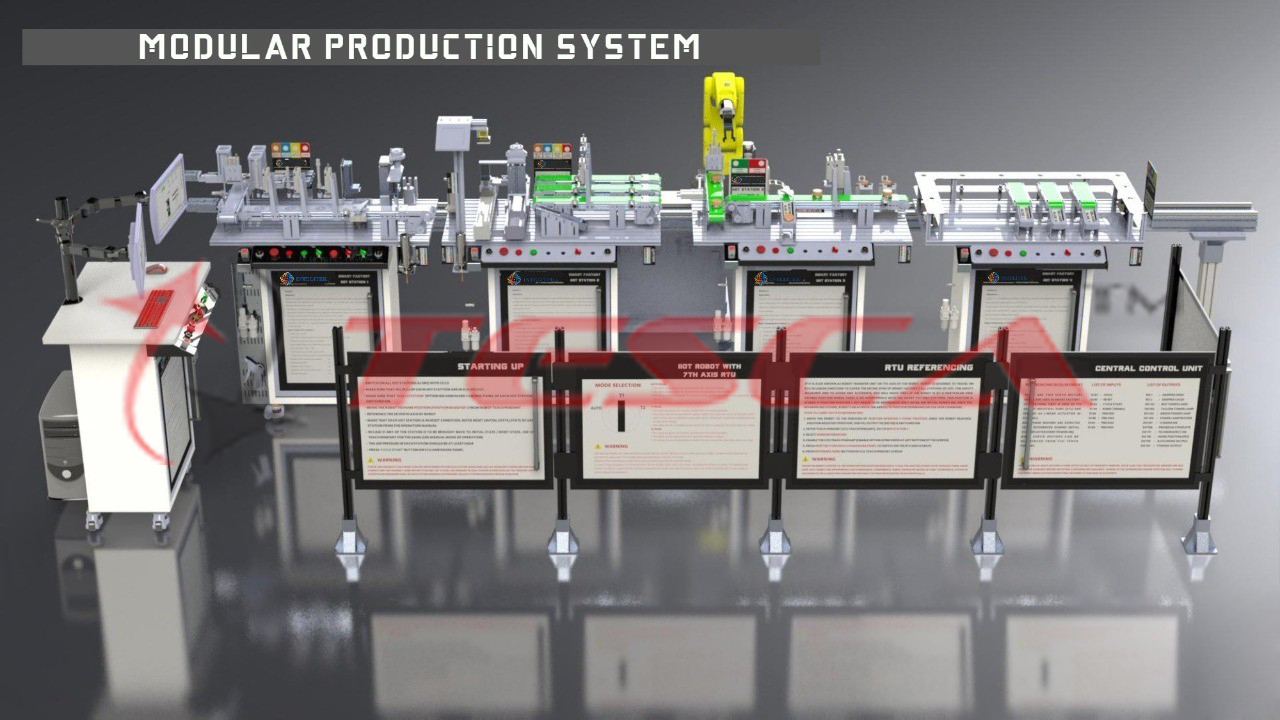

Modular Manufacturing Systems (MPS)

Order Code: 54038

Category: Mechatronics/ Robotics/ CNC Lab

54038 Modular Manufacturing Systems (MPS) are designed to give attendees hands-on experience with the latest industrial automation practices and technologies and create mechatronics projects. 54038 MPS stations are equipped with PLC and SCADA connect...

SPECIFICATION

54038 Modular Manufacturing Systems (MPS) are designed to give attendees hands-on experience with the latest industrial automation practices and technologies and create mechatronics projects. 54038 MPS stations are equipped with PLC and SCADA connectivity. The entire process is dynamically simulated in 3D with an OPC UA server that provides participants with the necessary information about the factory design and simulation. The entire system is equipped with Industry 4.0 connectivity. This helps mechatronics courses or mechatronics engineering to understand what is mechatronics?

Central Control Station

It is a central control station from where the operator can control the entire system in individual mode as well as in integrated mode. The workstation with two monitors has an ergonomic design. A hardware control panel is also mounted on the CCU for efficient operation management. Manual control unit with HMI for control are also connected to the CCU with connection ports RI 45. A central PLC that communicates with all machines is also mounted in the CCU control panel.

Software

The user can choose from a variety of software packages that can be integrated into modular production systems. SCADA: The whole system is designed and also controlled from industrial SCADA with unlimited tags (WinCCAdvance) Layout planning and optimization (Factory Simulation): It is a dynamic 3D process simulation software where students can design different MPS layouts and simulate the whole process. with more than 3000 components related to industrial automation such as portals, robots, AGVS already present in the library. Participants can also import 3D images of various pneumatic components into this Lne process simulation software. OPC UA Server: With OPC UA connectivity, the entire process can be dynamically simulated on factory simulation software. Students can effectively discover real process variants and identify bottlenecks in the Industry 4.0/IOT system: With this latest industrial technique, the user can select process parameters to be stored on a dedicated cloud server that can be accessed from anywhere in the world. Students can also choose the parameters of the process, which will be communicated immediately by email and SMS.

MPS 1: SORTING STATION (Based on Material & Height)

This is the first Intelitek MPS system station to be equipped with an automatic loading tube. It can be connected to MPS2. The basic operating concept of this MPS is material-based sorting along with the application of height sensing. There are two separate provisions for rejection in this MPS. The first reject device is mounted on the conveyor. Participants can choose a job based on material (MS/SS/PU) for further processing. Height based sensing is again a rejection mechanism. Students can choose the height of the task to be processed at the next station. In the event that there is no MPS 2, the participants can arrange the works according to their height.

- Operations & Sensing methods

- Sensing based on material

- Height based Sensing

- Accepting and rejecting according to user preference

- Introduction to rotary pick and place unit

- Autoloader operation

- Rod less cylinder operation

MPS 2: Sorting & Drilling (Sorting based on color)

Ideally, this is the second station in the Tesca MPS system that precedes MPS 1. A job can be directly transferred from station 1 to station 2. In the case of multi-station capability, station 2 will start immediately as soon as the job is transferred from station 1 to station 2 .In the case of individual mode, the user must place the job on the conveyor for the system to start. In the case of multi-station mode, the job is transferred from station 2 to station 3. In the case of individual mode, the processed job from station 2 is moved to the bin to finish the process. Station 2 houses a digital sensor that can be taught to sense a specific color. This digital color sensor input can be used to make process progress decisions or to display a count on a SCADA. Air drilling can actually drill for rough work as the operator chooses. The user can decide which jobs (based on color from MPS2/material from MPS1) will be drilled and which will not be drilled.

- Operations & Sensing methods

- Color based sensing

- Application of pneumatic drilling

- Acceptance and rejection based on user preferences

- Introduction to the pick and place rotary unit

- Operation of the linear transfer station

- Rod less cylinder action

MPS 3: Sorting Based on Weight

Ideally, this is the third station in the Tesca MPS system, which precedes MPS 2. The job can be directly transferred from station 2 to station 3. In the case of the Multi station option, station 2 places the job in the load cell in MPS 3. The measured weight of the job is displayed on digital display. An analog output is also provided from the amplifier that can be used to display the scale in SCADA. Depending on your weight or job, the user can choose to store the particulars job in the pallet.

- Operations & Sensing methods

- Sorting by weight

- Integration of load sensor with PLC and SCADA

- Operation of rotary collection and storage station

MPS STATION 4:4 Automatic Storage System with Index Table

This is ideally the last station in the Tesca MPS where the job is stored in one of the 8 memory cells. This station is equipped with stepper motors for the rotary indexer as well as the linear movement of the loader. Students can get hands-on experience with stepper motor control from PLC and SCADA. Both the rotary indexing unit and the linear transfer station must be referenced during commissioning. The coordinates of each stepper motor can be displayed on the SCADA. The user must decide in which pallet the order will be stored.

- Operations & Sensing methods

- Operation of linear sliding operation with stepper motor and PLC

- Operation of incremental position control

- Operation of the rotary indexing station

- Guidance/referencing of the stepper motor with PLC

- Calibration of the linear slide

Central Control Unit

It is an MPS end station that is connected to all other MPS stations via an Ethernet connection. MPS CCU is equipped with SCADA, through which participants can control individual stations and the entire MPS system in integration mode. Participants can choose between remote mode and station mode, through which the systems can be controlled remotely. CCU is ready for Industry 4.0. 3D simulation and design software is displayed on the second screen of the CCU. The entire MPS operation can be dynamically simulated on this software via an OPC UA connection.

- 1 SCADA(Siemenis WinCC Professional)

- Visual components 3D with OPCUA connectivity

- Mitsubishi RT Tool box with dynamic 3D simulation

- TIA Basic for ladder design and updating of individual station’s PLC

91-9829132777

91-9829132777