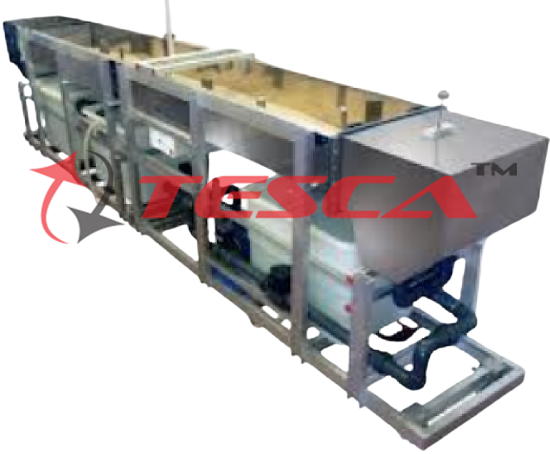

Mobile Bed & Flow Visualization Unit

Order Code: 32034

Category: Fluid Mechanics Lab

Study of open channel flows is a subject of interest in basic fluid mechanics and Hydraulics. A flow channel with a provision to control depth of flow over in the channel can provide a very useful tool to study several aspects of open channel flows. ...

SPECIFICATION

Study of open channel flows is a subject of interest in basic fluid mechanics and Hydraulics. A flow channel with a provision to control depth of flow over in the channel can provide a very useful tool to study several aspects of open channel flows. Adjustable Bed Flow Channel Unit is an essential equipment for fluid mechanics, hydraulics, civil, mechanical and related laboratories in science and engineering institutions.

Tesca Mobile Bed and Flow Visualization is a particularly useful unit to demonstrate the fluidization phenomenon in engineering. It makes it possible to study different situations of flow and mobile bed visualization related to civil engineering structures.

This unit may be used mainly in two study fields. The first one is the investigation of mobile beds, which are related to water courses and civil engineering structures. The second one is related to the visualization of the flow in two dimensions.

32034 consists of an horizontal channel through which a current of water flows slowly and at a constant depth. The working section is 2000 x 610 mm.

Study with the channel is simple thanks to the installation of different models and structures in it, making the flow circulate around them.

The unit is self-contained and it consists of an inlet tank with adjustable gate, channel with sand filters, discharge tank, water storage tanks, centrifugal pump, electromagnetic flow meter and set of models. The practical exercises with this unit are carried out by using water and sand. The sand bed can be placed on a polycarbonate sheet, which is located inside the flow channel..

List of Experiments:

1. Flow around model engineering structures.

2. Mobile bed experiments.

3. Meandering water courses characteristics.

4. Visualization of the behavior of boundary layers.

5. Demonstration of boundary layer suction.

6. Experiments of erosion.

7. Experiments of deposition.

8. Velocity distribution in duct flow.

9. Practices and tests with models for engineering.

10. Two dimensional flow visualization by the Ahlborn technique.

11. Hydraulic analogy to compressible flow. 12.- Sediment erosion and deposits.

12. Flow visualization and study of stream line patterns.

13. Demonstration of laminar and turbulent flow by flow visualization. (OPTIONAL)

Set of Models Included

Specifications:

The Mobile Bed and Flow Visualization unit 32034 is mounted on a metallic structure. This unit is divided into three sections: inlet tank,

working section (channel) and discharge tank. These sections are assembled through joints in order to get a complete assembly. There is a sand filter between the end of the channel and the discharge tank. Stainless steel inlet tank

Rectangular models with rounded ends

Rectangular models

Cylindrical models with adjustable gate. It is supplied with a control at the upper side of the tank which makes it possible to change the slope of such a gate. Dimensions: 530 mm x 710 mm x 530 mm.

Flow channel made of stainless steel, including a main rail with millimeter rulers (Longitudinal cross piece). A structure which includes a sub- rail (transversal crosspiece) is supported on the rail. It makes it possible to put a depth gauge to measure the water level and determine the Square model

Asymmetrical aero foil model

Pro?led rectangular model

Six ba?es to direct the water ?ow during

3 pairs of di?erent angles to

Triangular Model

A set of 12 ‘1’ shaped pro?les outline of the sand bed during the development of the practical exercises. Dimensions: 2000 mm x 710mm x 350 mm. The working section is 2000mm x 610 mm, and max. water depth is 120 mm approx.

The practical exercises with this unit are carried out by using water

and sand. The sand bed can be placed on a polycarbonate s h e e t , w h i c h i s located inside the flow channel.

Discharge tank made of stainless steel with overflow. It is divided into two parts, the one closer to the channel enables the sedimentation of sand, whereas the second part enables the removal of the water which overflows from the first section. Dimensions: 850 mm x 710 mm x 530 mm

Two storage tanks made of polyethylene of approximately 250 l. each one. It has a filter at the pump's inlet to retain possible residues.

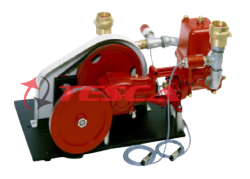

Centrifugal pump: flow range: 7.2 - 18 m /h; height: 14.4 19.70 M.W.C.

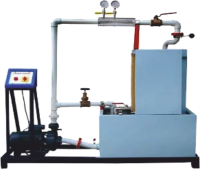

Electromagnetic flow meter: flow range: 10-70 l./min.

Membrane valve.

Two different size gates. A set of models included: Bridge piers models:

2 rectangular models.

4 cylindrical models.

4 square models.

2 profiled rectangular models.

2 rectangular models with rounded ends Triangular model.

Asymmetrical aerofoil model.

Six baffles to direct the water flow during the experimental tests.

A set of 12 “L” shaped profiles.

Three pairs of different angles to build additional models

Diagram in the front panel with similar distribution to the elements in the real unit.

Electronic console, including: Motor-pump starter.

Flow meter measurement display.

Cables and accessories, for normal operation.

Manuals: This unit is supplied with the following manuals: Required Services, Assembly and Installation, Starting-up, Safety, Maintenance & Practices Manuals.

A wide range of optional models available

Optional Models:

Float.

Tank strips.

Acrylic cylinder 90º angle walls.

Irrotational bend model.

Two side wall meanders.

Two bell mouth entries (right and left hand).

Vibration of a cylinder and box.

Weight.

Retaining block.

Services Required:

1. Water Supply.

2. Electrical Supply, 240/440V,3Ph, 50 Hz.

3. Sand bed: grain size: 0.4 - 0.8 mm. Sand bed thickness: 60 mm approximately

Overall Dimensions:

3350 x 710 x 1200 mm. approx.

The manual describes the theoretical and practical aspects of the apparatus, operation and maintenance supplied with the equipment.

91-9829132777

91-9829132777