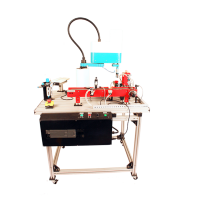

Miniature Industrial Production System

Order Code: 54037

Category: Mechatronics/ Robotics/ CNC Lab

The Miniature Industrial Production System. provides trainees to gain in-depth knowledge in the field of Robotics & Automation. Starts with the theoretical ideas to advanced practical applications. A combination of all the technologies used in th...

SPECIFICATION

The Miniature Industrial Production System. provides trainees to gain in-depth knowledge in the field of Robotics & Automation. Starts with the theoretical ideas to advanced practical applications. A combination of all the technologies used in the lab, MIPS is the perfect platform for learning industrial automation and mechatronics concepts. Includes a combination of various sensors, pneumatic components, precision actuators, microcontrollers & PLC, etc. to build a small production unit that makes a specific function.

List of Experiments

- Students should be able to design and implement automated systems using pneumatics.

- Students should be able to devise Assembly automated systems using Motors, Drives and sensor devices

- Students should be able to design and implement electro-pneumatic solutions for automated systems.

- Students should be able to apply PLC programming and implement it on PLC kits.

Available Modules

- Stacking Magazine Module

- Linear Transfer Module

- Lifting Module

- Slide Module

- Indexing Module

- Drilling Module

- Sensing Module

- Robotic Manipulator Module

- Conveyor Module

- Separating Module

- Storage Module

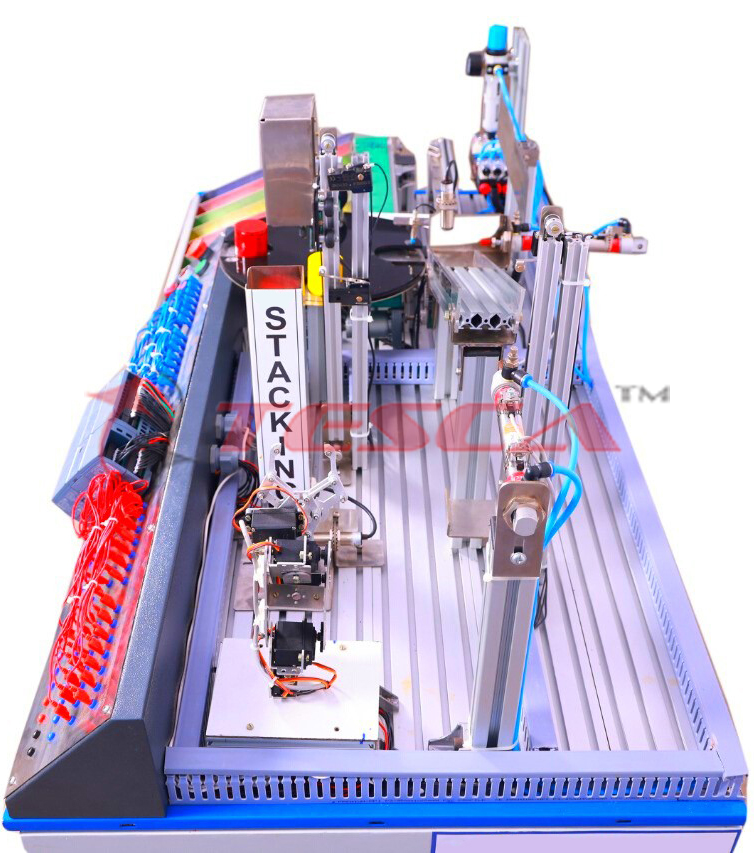

The processing station performs series of operation. The work piece moves from one process to other using the rotary index table which is operated by motors. The work piece from material handling station is processed here and sent to sorting station. It consists of following

Modules:

1. Indexing Module:

The index machismo is used to create the rotary motion to indexing which achieves a four position. The position feedback operation is done using infra-red sensors. Index plate has four spot - Loading spot, Drilling spot, Sensing spot & Conveyor dropping spot. Stepper motor & Drive is used to make the rotary indexing table. Proximity sensor is used in loading area to check the presence of work piece.

2. Drilling Module:

A drilling machine is attached to the linear actuator. Linear axis is driven by DC high torque motor. Limit switch places for position is used for feedback to ple.

3. Sensing Module:

Colour sensor is used to identify the colour of the work piece and inductive proximity is used to detect the material of work piece.

Maximum industrial technologies are used in this station to perform the material handling. This station receives work pieces from dispensing station and delivers to processing station. It consists of following modules,

1. Lifting Module:

This lifting module uses linear actuator to lift the work piece from dispensing station to slide module. The work piece is lifted vertically from lower level to higher level.

2. Slide Module:

The slide module has pneumatic cylinder slide which allows the work piece to travel from one end to another using gravity. The work piece travel from lifting module reaches the index table using slide module.

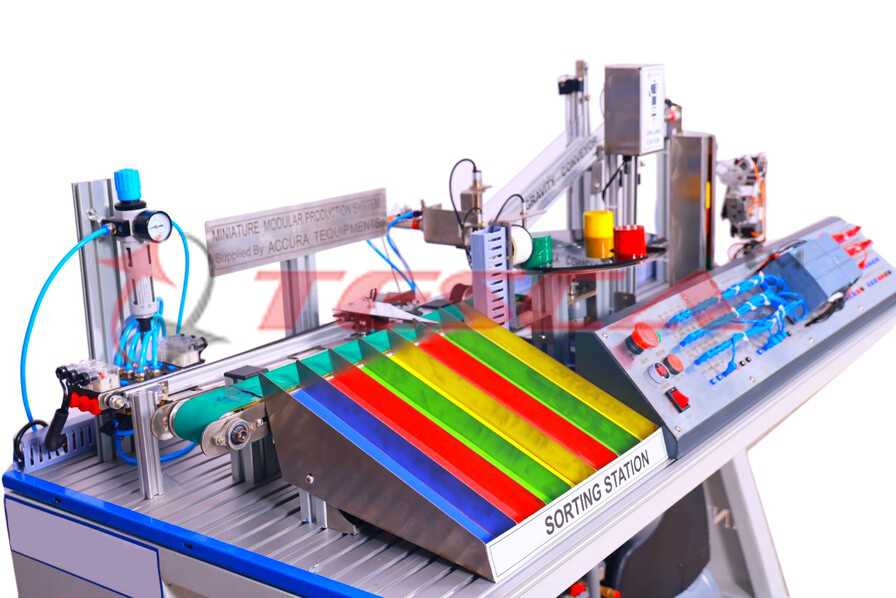

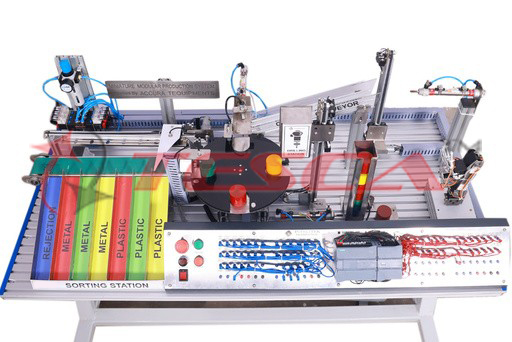

At this station, the finished parts are sorted based on material by two groups - _ metallic & plastic. In each group the parts are divided according to their color.

Finally, the parts are kept in separate crates for storage. It consists of following modules

1.Conveyor Module:

Transmission components mounted on the transmitter toward the final module - Includes 1 meter rubber conveyor belt, dr'um-mounted with bearings and rotating actuator - Driven by high-torched steel torque DC motor

2.Separator Module:

Linear Actuator using stepper motor operated module will separate the objects based on the color sensor feedback and Proximity sensor feedback for Metal.

3. Storing Module: -

Stores components in 8 crates - Depending upon the material & the colour of the components, stores them in separate crates.

91-9829132777

91-9829132777