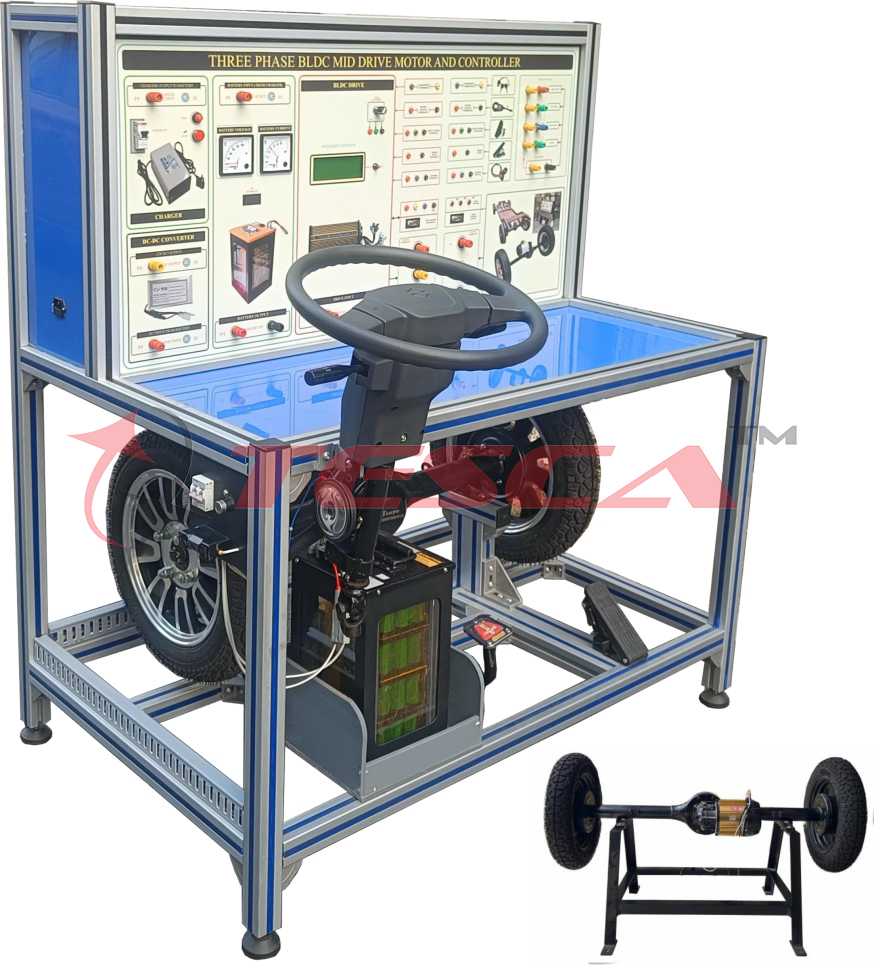

Mid Drive Motors , Drive And Control Panel (Switched Reluctance Motor )

Order Code: EV46012

Category: EV Technology Lab

Set up designed to study the connection procedure and testing procedure of electric 3 or 4 wheeler set up using various components of electric vehicle like battery , EV.Motors , drive etc , Set up consists of Control Panel ( with Drive, ...

SPECIFICATION

Set up designed to study the connection procedure and testing procedure of electric 3 or 4 wheeler set up using various components of electric vehicle like battery , EV.Motors , drive etc , Set up consists of

Control Panel ( with Drive, battery, charger etc)

Controller

- Type : MOSFET based Controller

- Input Voltage : 48-60VDC

- Maximum Current : 30A

Battery

- Type : lithium ion battery -LPF

- Voltage : 60v

- Power/Current : 18Ah

- Features : in built Smart BMS with PC interface Software and Bluetooth-Mobile App software -optional features.

Charger

- Type : MOSFET-based Charger

- Input Voltage: 170-250VAC

- Output Voltage: 62V

- Charging Current: 5A

- Charging Time : 4-5 Hour

- Features : Led's for status indicator

Panel

- Powder coated M.S Panel with diagram Stickered front panel to fix the Above Motor, controller and Battery and also to fix the below mentioned components

- Steering with Pedal Accelerator for speed control

- F/R selection switch, Left/Right indicator switch with Lamp

- Head light switch with Lamp, Horn switch with buzzer

- Brake control lever(optional)

- Digital LCD-indicator, To indicate

Speed in KM/H

Motor Speed in Rpm

Left indicator status

Right indicator status

Head light Indicator status

- ON/OFF Switch with Key

- DC-DC Converter for Light (48V TO 12V, 10A)

- Necessary Banana terminals provided for motor, Battery, Controller input and outputs terminations for external patching.

- Panel Meter for Battery voltage and Current

- Necessary terminations for controller control signal (like hall sensor, indicator, throttle) output and inputs for external patching.

- Necessary Fuse and MCB provided for battery, Motor

Features

- Provision / Facility to Interface with External IGBT Power Module and Controller set up (FPGA/MATLAB/DSPIC etc)- for Motor control and testing

Optional Features

- PC Software for BMS -Smart Battery (OP2)

- Blue tooth Mobile app-connectivity for BMS -Smart Battery (OP3)

Possible Experiments

- Study and testing of speed control of Hub Motor used in two wheelers

- Study and testing of 3/4 wheeler control components functions (pedal Acce function, F/R switch function, Left/Right indicator switch function, Head light switch function, Horn switch function, Brake control lever function, Digital LCD-Indicator function etc)

- Study and Testing of battery charging and discharging - BMS system using PCSoftware and Mobile blue-tooth App (User will provide computer/Mobile)- optional features

The performance of this model could even better than the performance of bench top oscilloscope. It has 4 analog channels, 1GSa/s real-time sampling rate, 2mV-10V/DIV input sensitivity, and 250MHz bandwidth. USB2.0 Interface powers it, plug and play device with small size which is easy for carrying. High cost performance, pass/fail test, resourceful trigger function, dynamic cursor tracking, waveform record and replay function

Three Phase Switched Reluctance Motor Order Code-EV46012M

• Voltage: 48V

• Power: 1KW or 3KW (Optional)

• Speed: 2500 RPM

• Feedback:3 numbers of Hall sensor

• Differential set up 10:1 Gear Ratio Fitted with stand and Tire, drum

Optional: Pc Based Measurement And Acquisition System For Motor Voltage And Current : Order Code - EV-DAQ

For more Information Click heare

91-9829132777

91-9829132777