Mechatronics Automation Training Kit For Bottling Packaging Operation. Industry 4.0 Compatible

Order Code: 54031

Category: Mechatronics/ Robotics/ CNC Lab

This system is a complete practical demonstration bringing a miniature bottling plant to the Laboratory. Function of the system is as follows: Containers / Bottles are placed / dispensed on to the belt conveyor. Conveyor will sense the presence of ...

SPECIFICATION

This system is a complete practical demonstration bringing a miniature bottling plant to the Laboratory.

Function of the system is as follows:

Containers / Bottles are placed / dispensed on to the belt conveyor. Conveyor will sense the presence of bottles. If present, it will carry the bottles to the Linear Conveyor System. Linear Conveyor will transport each bottle to the 2 axis (pick & place) module. The gripper of the transfer unit will place the bottle on to the Rotary Indexing Table.

The motorized rotary module will index the bottle through Volumetric filling modules, capping module. At the end, a rotary transfer module will transfer the filled & capped bottle / container to the weighing module. Once weighing is done, XY palletizing module will store it in the pallets. The weights can be used for sorting on the palletizer As an option, the system can be equipped with a colour sensor and a second filling unit & second capping unit for two different types of material filling [example Cola (black plastic pellets) & Orange (orange plastic pellets)]. The XY palletizer can be upgraded to servomotors. The modules can be configured for inspection & sorting also. All the modules are standard & sturdy can be used for different automation application. The system is supplied with complete PLC control module. Trainers can introduce real-life faults in the system and thus train the students in troubleshooting techniques

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in – In Automation Technology

- concepts in automation.

- Applications of automation in industries

- Advanced applications of Sensors, Pneumatics in automation.

- Demonstrate a familiarity in the working of such systems & Production Planning

- Learn Robotics & Automation technology.

- Study the actual control system used in industries

- In-depth training in fault detection & correction

- Learn about the maintenance & servicing of these systems

TECHNICAL SPECIFICATIONS

- Key Advantages of Tesca Mechatronics MAPS systems:

- The industry is looking for students who have skills and knowledge of integrated engineering technologies and problems solving skillsets. Tesca’s Adv Mfg & Automation training solutions are designed to deliver the same through our Industry 4.0 Smart Factory, and Smart Mechatronics products. We have already delivered over 50+ systems globally to highly reputed educational institutions.

- The Tesca product portfolio is ready for Industry 4.0 integration and IIOT Training

- Our training solutions are developed with focus on delivering skills and transferrable knowledge that students can carry from their classroom/ labs to the industry

- Our hardware is accompanied with world-class online training courses (SKILLON365)

- IOT Ready: Equipment is Internet of Things ready and can be interfaced with IoT platform. This is an option.

- Digital Twin: Digital twin is available for all mechatronics system as an option.

- Approach to the design, construction, training and future ready concepts aligned with European and American educational system

- Train on Automation in Circuit: Understand how automation works - from simple to complex circuits

- Train on Automation in Application: Understand how automation works in industries - from simple to complex applications, programming & control

- Train on Automation in Maintenance:Understand how to identify faults and troubleshoot in automation -variety of exercises to train in this area

- SKILLON365: Online courseware that gives the users flexibility of selecting courses from a variety of technologies and changeable each year.

- Tesca modules are built for durability, robustness and performance, high quality and aesthetic finish

- Highly reliable components: Pneumatics from Festo, PLC from Siemens, Sensors for reputed international manufacturers, Mechanical components from reputed international industrial suppliers

- Serviceability: We support our product globally through our reselling partners and through "Going Digital with

Tesca" platform, where you can connect with our service specialists through asynchronous communications or synchronous communication means

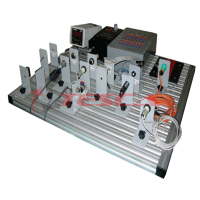

MAPS 1 -Weighing & Palletizing System Consists off the following

- Complete workstation mounted on a aluminium profile plate with operating console, consisting of:- 1No.

- Belt conveyor- 1No.

- Linear pick & place unit (LPP) Module- 1No.

- Linear Conveyor Module (Horizontal transfer unit)- 1No.

- Rotary Pick and Place (RPP) Module (Transfer Module)- 1No.

- 4 Station Rotary Carousal Table (Rotary Indexing Table)- 1No.

- Dispensing module- 1No.

- PLC - SIEMENS- 1No.

- Safety light curtain - Optional

- Mobile Trolley- 1No.

1. Aluminium Profile Plate

Aluminium Profile Plate for mounting all pneumatic & other components to the modules. A Mobile trolley which can fit the aluminium profile plate is provided as optional. All electrical and electronic items shall be housed in the bottom of the trolley below the platform

2. Belt Conveyor Module

The conveyor module conveys the part from one end to another. Specification:

- Motor : 12 V DC power motor

- Length : 420mm

- Height : 60mm

- Width : 40mm

- Belt : Nylon fabric belt

- 4 gates provided for fixing sensors and part ejection.

- Knob screw (1 no) and T-nuts of diameter M6 are provided for quick fixing of the module on profile plate.

3. The Linear Pick And Place (LPP) Module

Specification:

- Double acting pneumatic cylinders : 2 Single acting pneumatic cylinders : 1 Reed switches : 4

- Solenoid coils : 5

- Horizontal stroke : 80mm

- Vertical stroke : 20mm

- Mounting : Knob screw (1no)

- Scope of supply

- Quick mounting knob screw and T-nut – 1 Pneumatic module

- Air supply module

4. Linear Conveyor Module (horizontal Transfer Unit)

The horizontal transfer unit is fitted with a double acting cylinder and stopper is used to transfer material. Type : Electro-Pneumatic System

Cylinder : Pneumatic Rod-less cylinder

Sensor : Magnetic reed switch -2 No. of I/O elements : 2 inputs & 1 outputs

5. The Rotary Pick And Place (RPP) Module

The rotary pick and place (RPP) module picks the work piece from one position, horizontally rotates by 90° and then places the work piece to another position.

The part shall be moved to next location for processing, in a rotary manner. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T- slotted n tube.

Specification:

Double acting pneumatic cylinders : 3 5/2 Single acting solenoid valve : 1 5/2 Double acting solenoid valve : 2 Reed switches : 4

Rotation angle : 90º

Vertical stroke : 20mm

Mounting : Knob screw (1no) Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

6. Filling & Capping Module

The workpiece from the transfer station is placed on a 6 station rotary indexing table. A sensor detects the presence of the workpiece and signals the filling module to start the filling process. The filler is brought down using double - acting cylinder, guided by a guide unit. Inspection of Filling is done by optical sensors. Following the filling process, the table will rotate to the next station and the capping module will cap the workpiece. The process is repeated till the table completes a rotation until no more workpieces are detected. Inspection of capping is done by an optical sensor.

Specification:

Double acting pneumatic cylinder : 1

5/2 Single acting solenoid valve : 1

Reed switches : 2

Horizontal stroke : 50mm

Mounting : Allen screw

Quick mounting knob screw and T-nut – 2 Pneumatic module

Air supply module

7. Rotary Indexing Table (rotary Carousal Table)

The rotary indexing module indexes and moves the work piece to the destination position in its platform. Rotary indexing module is to move workpiece location in fixed intervals up to 3 indexing which can be further expanded based on the project. The customer can specifically request for additional indexing. The workpiece shall be indexed to next location for processing, in a rotary manner. The module is a stand alone functional unit with readiness to connect electrically to PLC and I/Os to actuate the function.

Specification:

Mounting : Knob screw (2nos)

Home sensor : 1

Scope of supply

Quick mounting knob screw and T-nut – 2 Pneumatic module

Air supply module

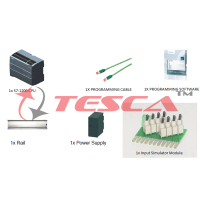

8. PLC Specifications:

- Siemens PLC S7-1200

- 24 Digital input,16 Digital output & 2 Analog input

- Process image

- 1024 bytes for inputs, 1024 bytes for outputs"

- Work memory (integrated)-100 KB, Load memory (integrated)-4 MB

- Software:TIA Portal V13 step7

- 24V Power supply, 4.5 Amps

- ON/OFF Switch

- 110/ 230 V Male Plug

- Fuse Bank

- E-Stop, start, stop Switch

- 12v power supply

- 24v Compact Relay

- Sticker Layout

9. Air Supply Module (FRL Unit)

This consists of the air filter, pressure regulator and lubricator unit, and supplies compressed air to control the movement of the pneumatic cylinders.

Pressure regulator – The pressure regulator maintains a constant output pressure independent of pressure fluctuations and air consumption. The output pressure can be reduced by means of a secondary venting without compressed air consumers.

Air filter – The air filter removes contamination, pipe sinter, rust and condensate from compressed air.

Lubricator – The proportional lubricator adds precision adjustable quantity of oil to the compressed air. The oil droplets are atomized just downstream from proportional valve in the air duct. The oil mist component is proportional to the compressed air flow rate.

Scope of supply

Quick mounting knob screw and T-nut – 1 shut-off valve and 5m tube of diameter 8mm

10. Weighing Module

The weighing Module weight the material using a load cell and shows the value in the PLC Specification:

Type : Electrical System Required Work piece : Cylindrical Work piece Load cell for weighing module : 1 no.

Amplifier unit with relay output

11. Mobile Trolley

Mobile Trolley is a profile frame on wheels that provides a base module for the MAPS – Stations. The mounting surface is a T-grooved plate for positioning the various modules / stations and allows a variety of adjustments. This allows for the systems to be moved to different locations such as simulation lab, classroom to lab etc.

DIMENSIONS AND WEIGHT OF MAPS

L x W x H : 1200 x 900 x 940mm

Weight : 120 Kgs (approx.)

Experiments Basic Exercises:

- To run the conveyor continuously when the start switch is pressed.

- To run the conveyor when start button is pressed and automatically stop it after a time delay 10 sec.

- To move the Horizontal conveyor when the start is pressed and moves it back to home position after 10 sec.

- To move the Vertical cylinder come down pick the bottle and move up and open the gripper.

- To make the Vertical cylinder to come down pick the bottle and places it in the bin.

- Program to Start and stop the conveyor using single button at any locations.

- To actuate the conveyor only when both button pressed simultaneously (Green & Red).

- Actuate the conveyor for the first press and then actuate horizontal transfer unit for the next press of the button (acting as manual Trigger)

- Transfer the job from conveyor end to horizontal transfer unit position.

Advanced Exercises:

- Programming Linear Indexing Module with station control.

- Programming Rotary Indexing Module with memory array for the station address.

- Programming and control of changer module and integrating of weighing module to form a closed loop system.

- Programming & control Linear Transfer Module.

- Pulse control program to activate the palletizer to pick the bottle from the weighing unit and places it in the pallet table (1, 1).

- Program to manual triggered rotary indexing module to rotate by two slots and carry out the capping process and move it to next position.

- Program to manual triggered rotary indexing module to rotate by three slots and carry out the unloading operation to place the bottle in next module (Weighing module).

- Program to sensor trigger/manual triggered and to make the Vertical cylinder to come down pick the bottle and places it in the next module (Rotary module).

- Program for Auto conveyor transit / return for material transfer with timer and Feedback control.

- Full complete system – sequence.

REQUIRED EQUIPMENT AT SITE AND UTILITIES TO BE PROVIDED BY THE BUYER DURING COMMISSIONING, DEMONSTRATION & TRAINING For MAPS

- Compressor - 100 Litre tank Capacity, 6 to 8 Bar (100 – psi) - 1No

- Desktop computer required with specification below

- Operating System : Windows 7 Professional or higher

- Processor Required At least 2.4 GHz or equivalent, RAM : at least 4 GB

- 19inch LCD Monitor - 1 no

Set of Spares

- Photoelectric sensor : 1 Nos.

- Capacitive sensor : 1 Nos.

- Fuse : 10 Nos.

- Relay : 2 Nos.

- Workpieces : 4 Nos.

- Pneumatic hose : 2 mtr

91-9829132777

91-9829132777