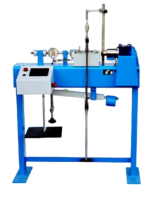

Marcet Boiler

Order Code: 21224953.6.4

Category: General Lab Equipment II

Compact, sturdy, Table Top Model Fully instrumentation for experimentation of heat transfer. Simple design. Marcet Boiler Model is designed to study the relationship between the temperature and pressure of the steam. Marcet Boiler is made of hea

SPECIFICATION

Features :

- Compact, sturdy, Table Top Model

- Fully instrumentation for experimentation of heat transfer.

- Simple design.

Marcet Boiler Model is designed to study the relationship between the temperature and pressure of the steam. Marcet Boiler is made of heavy-duty stainless steel shell. It has a Mercury thermometer for readout of temperature inside the boiler. A water heater has been provided as a heating element. Heater control device also has been provided. The panel will be housed in the Tripod for easy indicator / readout.

Specifications

1. Measuring a vapour pressure curve for saturated vapour

2. Boiler with insulating jacket

3. Temperature limiter and safety valve protect against overpressure in the system

4. Bourdon tube pressure gauge to indicate pressure

5. Digital temperature display

System Components

- ? Safety valve,

- ? Boiler with insulating jacket,

- ? Bourdon tube manometer,

- ? Switch box with temperature display,

- ? Drain valve,

- ? Heater,

- ? Overflow Valve,

- ? Temperature sensor

- ? Optional ‘Sci-Cal’ software for data acquisition via USB under Windows 7, 8.1, 10

- Technical Specifications

- ? Insulated vessel (water boiler); material: stainless steel, capacity: 2 l. approx.

- ? An immersion heating element (computer controlled), power: 2000W., limit of the maximum

- heating temperature: 200ºC.

- ? A security valve and a high pressure switch to limit the working pressure to 18 bars.

- ? For safety purposes, a pipe with a regulation valve, situated in the lower side of the boiler

- allows the boiler, to be filled with water using a hose. Another pipe with a regulation valve,

- situated in the upper side of the boiler, allows the checking of the water level using a hose.

- Both pipes allow the draining of the water from the boiler and to direct any vented steam

- away from the working area to a suitable drain.

- ? A "J type" temperature sensor to measure the steam temperature at the water boiler.

- ? One pressure sensor to measure the steam pressure at the boiler, range: 0-25 bar.

- ? This unit is protected by transparent sheets with orifices to allow handling the valves.

- ? A PID control enables to get a constant saturated steam temperature with the heating

- element.

- Optional

- ‘Sci-Cal’ Computer Control Software

- ? PID Computer Control + Data Acquisition + Data Management.

- ? Compatible with actual Windows operating systems. Graphic and intuitive

- simulation of the process in screen. Compatible with the industry standards.

- ? Registration and visualization of all process variables in an automatic and

- simultaneous way.

- ? Flexible, open and multi-control software, developed with actual windows graphic

- systems, acting simultaneously on all process parameters.

- ? Analog and digital PID control.

- ? Menu for PID and set point selection required in the whole work range.

- ? Management, processing, comparison and storage of data.

- ? Sampling velocity up to 250 KS/s (Kilo samples per second).

- ? Calibration system for the sensors involved in the process.

- ? It allows the registration of the alarms state and the graphic representation in real

- time.

- ? Comparative analysis of the obtained data, after the process and modification of

- the conditions during the process.

- ? Open software, allowing to the teacher to modify texts, instructions. Teacher’s

- and student’s passwords to facilitate the teacher’s control on the student, and

- allowing the access to different work levels.

- ? This unit allows the 30 students of the classroom to visualize simultaneously all

- results and manipulation of the unit, during the process, by using a projector or an

- electronic whiteboard.

- ? This module requires Control Interface Module and Data Acquisition.

Interface In-built Module:

This control interface is common for the ‘Sci-tech’ trainers and can work with one or several

trainers.

The Control Interface is part of the SCADA system.

Control interface with process diagram on the front panel.

The unit control elements are permanently computer controlled.

- Simultaneous visualization in the computer of all parameters involved in the process.

- Calibration of all sensors involved in the process.

- Real time curves representation about system responses.

- All the actuators’ values can be changed at any time from the keyboard allowing the analysis

about curves and responses of the whole process.

- Shield and filtered signals to avoid external interferences.

- Real time PID control with flexibility of modifications from the computer keyboard of the PID

parameters, at any moment during the process.

- Real time PID control for parameters involved in the process simultaneously.

- Proportional control, integral control and derivative control, based on the real PID

mathematical formula, by changing the values, at any time, of the three control constants

(proportional, integral and derivative constants).

- Open control allowing modifications, at any moment and in real time, of parameters involved

in the process simultaneously.

- Three safety levels, one mechanical in the unit, another electronic in the control interface

and the third one in the control software.

Experiments :

- ? Study of Boiler (Study type experiment)

- ? Study of relation between pressure and temperature of wet steam may be found experimentally.

Requirements:

- Electric supply 220V AC, 50 Hz

- Steam line

- Water line

91-9829132777

91-9829132777