Jacketed Vessel (To be used with: Power Supply For Heat Exchangers)

Order Code: 24258098.52

Category: General Lab Equipment V

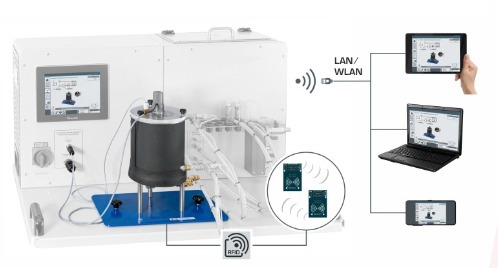

JACKETED VESSEL (To be used with: POWER SUPPLY FOR HEAT EXCHANGERS). Heating using jacket or coiled tube; stirrer for improved mixing of medium. Features stirrer for improved mixing of medium,- heating using jacket or coiled tube,- int...

SPECIFICATION

JACKETED VESSEL (To be used with: POWER SUPPLY FOR HEAT EXCHANGERS).

Heating using jacket or coiled tube; stirrer for improved mixing of medium.

Features

-

stirrer for improved mixing of medium,- heating using jacket or coiled tube,- intuitive experiment execution via touch screen ,-integrated router for operation and control via an end device and for screen mirroring on up to 10 end devices: PC, tablet, smartphone,- automatic identification of accessories via RFID technology.

-

Learning objectives/experiments,- in conjunction with supply unit,-- function and behaviour during operation of a stirred tank with double jacket and coil,-- plotting time functions: heating mode with jacket, heating mode with coiled tube,-- influence of a stirring machine,-- comparison with other heat exchanger types,- PLC software specifically adapted to the accessories used,-- learning module with theoretical fundamentals,-- device description,-- guided experiment preparation,-- execution of the experiment,-- graphical representation of the experimental section with measured values for temperature,-- data transfer via WLAN/LAN for versatile external use of measured values and screenshots e.g. evaluation in Excel.

Specification

-

stirred tank for connection to base unit

-

heating using jacket or coiled tube

-

stirring machine can be used in all modes

-

speed of stirring machine adjustable using WL 110

-

visible working area due to transparent cover

-

recording of temperature using base unit and additional temperature sensor for measuring temperature in tank

-

automatic identification of accessories via RFID technology and use of the corresponding PLC software

-

experiment execution and display of the measured values via touch screen (HMI),

-

screen-mirroring: access to ongoing experiments and their results from up to 10 end devices simultaneously via the local network

-

hot and cold water supply from base unit.

-

Technical data: Stirred tank -nominal capacity: approx. 1200Ml. Stirring machine- speed: 0...330min-1, Heat transfer surface,- jacket (stainless steel): approx. 500cm2,- coil (stainless steel): approx. 500cm2 . Measuring ranges- temperature: 0...100°C

91-9829132777

91-9829132777