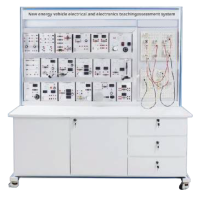

Intelligent Testing Platform for New Energy High-Voltage Electric Control Assessment System

Order Code: NEE96

Category: New Energy Equipments

Product Requirements The intelligent test platform of the new energy high-voltage electric control assessment system conducts multi-degree-of-freecom simulation tests on new energy vehicles. The simulation can more intuitively observe various syst...

SPECIFICATION

Product Requirements

The intelligent test platform of the new energy high-voltage electric control assessment system conducts multi-degree-of-freecom simulation tests on new energy vehicles. The simulation can more intuitively observe various systems and various actions and phenomena of various working conditions through the test bench, and measure the vehicle simulation working condition test through the host computer. Let the students have a deeper understanding of the mechanism and control strategy of new energy vehicles.

The test bench can be used as a verification test platform for the development of the three electric system of new energy vehicles, which is of great help to improve the development capabilities of engineers and complete the three-electric joint debugging experiment.

Features

- The new energy vehicle electrical control system test bench is a customized device for simulating the new energy vehicle electronic control system, which is used in the research and development, teaching and practice of the new energy electric vehicle. The bench contains the three core electronic controls of new energy vehicle, the vehicle controller VCU, the motor controller MCU, and the battery management system BMS, and provides the hardware schematics and software source code of the VCU MCU BMS respectively. Student or engineers can modify the code based on the software and hardware platform for the secondary development and verification.

- It has 36 strings of lithium iron phosphate batteries and is equipped with a self-developed BMS, which can complete the BMS’s function of the monitoring the voltage, temperature and current of lithium batteries.

- It contains a motor-to-motor platform with the ability to run the motor in four phases. The motor-to-motor platform is equipped with a dynamic torque sensor that can dynamically measure the torque, speed, power, efficiency and other key parameters of the motor.

- The VCU MCU BMS of the bench adopts the industry-leading V-shaped development process, and the algorithm part is modeled in MATLAB and generates code. It meets the requirements of rapid development and

- iteration in the automotive industry. Equipped with wireless fault setting system, intelligent detection terminal and other software to enable teachers to assess students intuitively.

Composition of the New Energy Test Bench

- The new energy test bench is built based on real automobile parts and aluminium and iron materials to simulate the body.

- The operation panel adopts a simulation teaching-style easy-to-understand operation panel, integrating various operation switches and analog knobs to achieve the test of some special working conditions.

- The new energy vehicle controller adopts the self-developed, advanced NXP 32-bit MPC5744 as the mein chip for modeling and development

Technical Requirements

- The test bench controller can complete data monitoring on the host computer.

- The test bench can simulate various working conditions.

- The control panel has corresponding working indicator lights and measuring holes, and the working order and status of each workpiece can be understood according to the indicator lights: The actual voltage of the wires on the schematic diagram can be measured with a multimeter according to the measuring port.

- The schematic diagram on the operation panel needs to be linked to the physical controller.

91-9829132777

91-9829132777