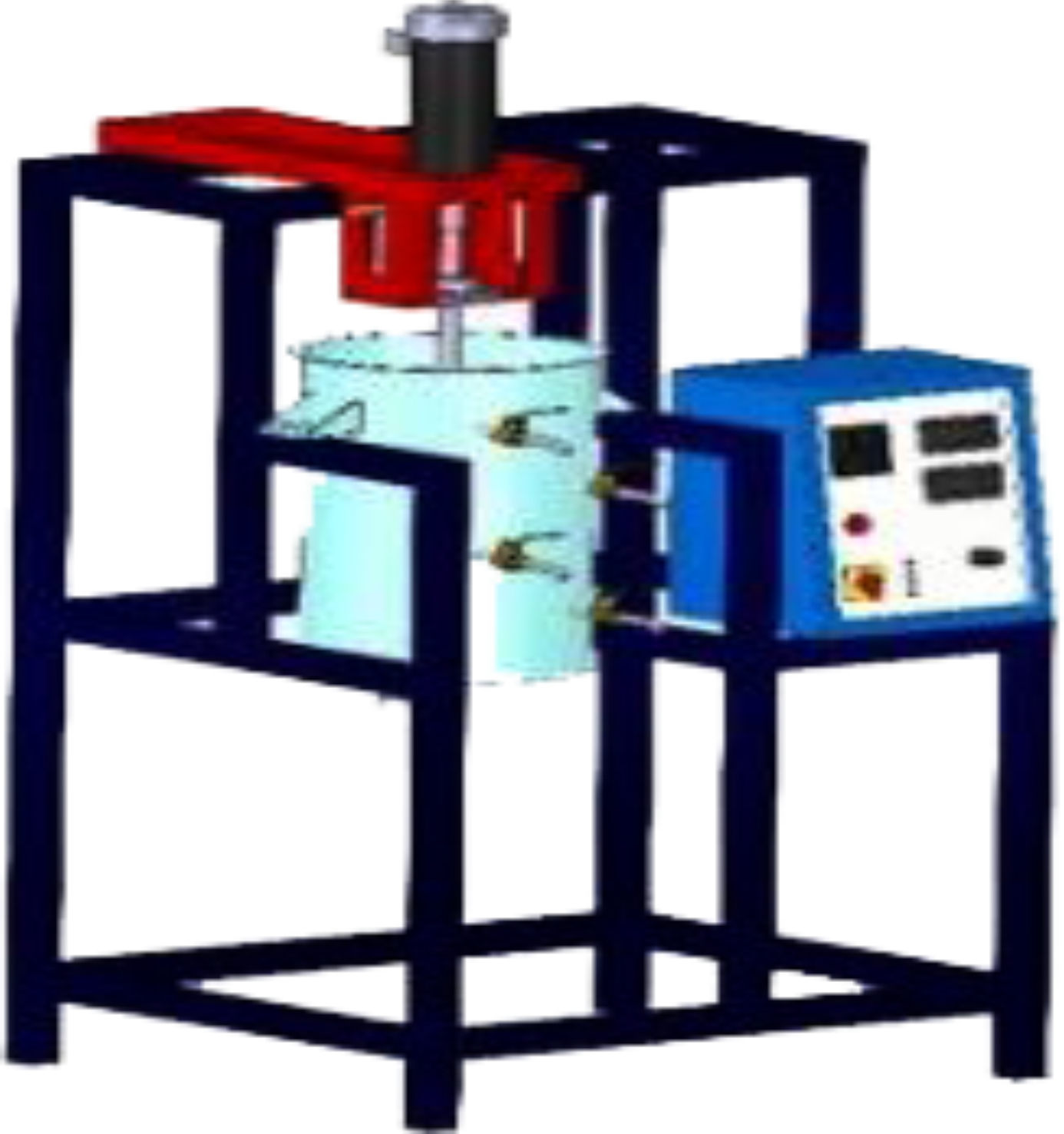

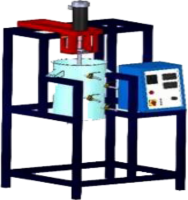

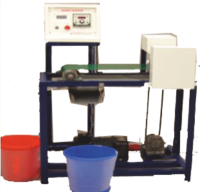

Fluid Mixing And Power Consumption In Agitated Vessel

Order Code: 14213

Category: Mechanical Operation Lab

Introduction: For a processing vessel to be effective the volume of fluid circulated by the impellers must be sufficient to sweep out the entire vessel in a reasonable time. The velocity of the stream leaving the impeller must be sufficient to carry ...

SPECIFICATION

Introduction: For a processing vessel to be effective the volume of fluid circulated by the impellers must be sufficient to sweep out the entire vessel in a reasonable time. The velocity of the stream leaving the impeller must be sufficient to carry the current to the remotest parts of the tank. Liquids are most often mixed in some kind of tanks or vessels, usually cylindrical in form and with a vertical axis.

Specifications:

Tank:Material Stainless Steel.Dia.300mm, Depth 400mm (approx.)Stirrer: SS Impeller with SS Shaft coupled to Standard make FHP.Variable Speed Motor and Drive.Agitator:Stainless Steel shaft & impellers (i.e. one propeller & one turbine)Baffles:Material Stainless Steel,4 Nos. 2” width. (detachable).Sampling point:4 Nos.at random locations.Control Panel Comprises of:RPM Measurement:Digital RPM Indicator,Non Contact type with Proximity sensor.Digital Voltmeter:0-300 Volts,Ammeter:0-5 Amps.

91-9829132777

91-9829132777