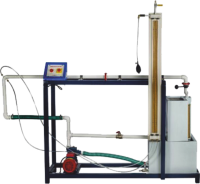

Flow Meters Trainer

Order Code: 32051

Category: Fluid Mechanics Lab

Features: 1. Comparison and calibration of different flowmeters 2. Direct comparison of flow measurement of various flow meters 3. Used for comparing and showing the accuracy, losses, and...

SPECIFICATION

Features:

1. Comparison and calibration of different flowmeters

2. Direct comparison of flow measurement of various flow meters

3. Used for comparing and showing the accuracy, losses, and use of fundamental in fluid mechanics applications that become important in many process engineering systems. Different types of flow meters are used based on applications and processes. It becomes important to study the flow measurement using different types of flow meters and their calibration.

Tesca Flow Meter Measurements & Calibration Trainer consists of a Venturi meter, variable area meter, and an orifice flow meter and pitot tube, installed in a series configuration to permit direct comparison. A flow control valve permits variation of the flow rate through the circuit. Pressure tappings are incorporated so that the head loss characteristics of each flow meter may be measured. These tapings are connected to a four or eight- tube manometer bank incorporating a manifold with an air bleed valve. Pressurization of the manometers is facilitated by a hand pump. The circuit and manometer are attached to a support framework that stands on ‘Tesca Hydraulic Bench 32097’. The Hydraulic Bench is used as the source of water supply and for calibrating the volumetric flow of the meters.

Optionally, differential pressure sensors, electro-magnetic flow rate sensors also available

Experiments:

flow meters 1. Directly comparing flow measurement using

4. ‘Quick-change’ flow meter adaptors and pressure connections

5. Minimum four-tube manometer to show flow meter and overall pressure changes

6. Nozzle flow meter

7. Downstream flow control valve

8. Manometers with a common manifold fitted with an air valve

9. Hand-pump included which can be used to increase the air pressure in the manifold

10. Optionally differential flow meters, Rotameters, Electro-magnetic flow meters can be available

Flow measurement study plays an important role

a Venturi meter, Variable area meter, and Orifice plate.

2. Calibrating each flowmeter using the volumetric measuring tank of the Hydraulic Bench.

3. Comparison of pressure drops across the device.

4. Accuracy of orifice flowmeters

5. Losses and k value

6. Accuracy of Pitot tube flowmeters

7. Losses and k value

8. Calculation of the coefficient of discharge

9. Velocity profile

8. Accuracy of Venturi flowmeters

Specifications:

Flow Meters

Used for comparing and showing the accuracy, losses, and use of fundamental flow meters

‘Quick-change’ flow meter adaptors and pressure connections

Minimum four-tube manometer to show flow meter and overall pressure changes

Nozzle flow meter

Downstream flow control valve

Calculation of the coefficient of discharge

Manometers with a common manifold fitted with an air valve

Hand-pump included which can be used to increase the air pressure in the manifold

Orifice Flow Meter

Sharp-edged orifice flow meter for use with the Flow Meter Calibration unit

Shows the accuracy and use of a sharp-edged orifice flow meter of ISO 5167 standard

Allows the user to measure pressures before and after an orifice for a given rate of flow

Manufactured in accordance with the latest EU directives

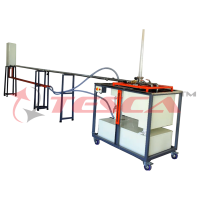

Pitot Tube

Pitot tube flow meter for using with the Flow Meter

Calibration unit

Shows the accuracy and use of a Pitot tube flow meter

Flowmeter fits quickly and easily into place between the adaptors in the base unit of the Flow Meter Calibration unit

The manometers of the calibration unit show the pressure differences at the flow meter and across the overall flow

Meter Assembly

A precision micrometer head allows the user to accurately adjust the position of the Pitot tip that traverses acros the inside of the pipe

The tip measures the change in pressure across the pipe for a given flow rate

A second tapping in the pipe wall measures the ‘static’ pressure

Plots of these pressures show the velocity profile in a pipe and explain the ‘boundary layer’ and surface friction in pipes and flow channels

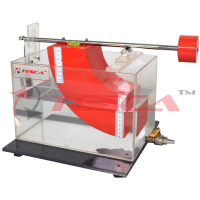

Venturi Flow Meter

Venturi flow meter is used with the Flow Meter Calibration unit

Shows the accuracy and use of a Venturi flow meter

Flowmeter fits quickly and easily into place between the adaptors in the base unit of the Flow Meter Calibration unit

The manometers of the calibration unit show the pressure differences at the flow meter and across the overall flow

Meter Assembly

Made to ISO standards, the flow meter allows the user to measure pressures before and after a Venturi constriction for a given rate of flow

Services required

Water Supply

Mains Power Supply: 220~240V, 50Hz, 1 phase

91-9829132777

91-9829132777