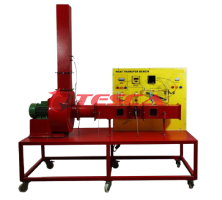

First Law of Thermodynamics Test Apparatus: Heat Conduction and Convection

Order Code: 32377

Category: Thermodynamics Lab

Features Effect of heat conduction and convection on heat transfer Experiments with still air on free convection Functions of the optional software: educational software, data acquisition, system operation part :Fundamentals of Heat Transfer ...

SPECIFICATION

Features

Effect of heat conduction and convection on heat transfer

Experiments with still air on free convection

Functions of the optional software: educational software, data acquisition, system operation part :Fundamentals of Heat Transfer

Heat conduction and convection are among the three basic forms of heat transfer and often occur together.

Heat Conduction and Convection Apparatus 32377 allows basic experiments on both forms of heat transfer: heat conduction and convection.

At the heart of the unit are different metal samples. The samples are placed on a heater and are heated on one side. The heat is conducted through the sample and dissipated to the environment.

The sample used behaves like a cooling fin. In addition there are fans below the sample. The flow rate of the fans is continuously adjustable in order to influence the convective heat transfer. The air flow is conveyed evenly around the sample. Consequently, besides conducting the experiment with still air (free convection), it is also possible to conduct experiments with flowing air (forced convection). The effect of different materials on heat conduction is demonstrated by comparing different samples.

The experimental unit is equipped with five temperature sensors. Heating power and flow velocity of the air flow are adjusted and displayed via the software.

The microprocessor-based instrumentation is well protected in the housing. The software consists of a software for system operation and for data acquisition and an educational software. With explanatory texts and illustrations the educational software significantly aids the understanding of the theoretical principles. The unit is connected to the PC via USB..

Specifications

Investigate heat conduction and convection using the example of a cooling fin

Cooling fin: sample heated at one end, made of metal

6 Samples made of different materials and with different lengths

6 Fans for experiments with forced convection

Continuously adjustable heating power and fan power

Display of temperatures, heating power and air velocity in the software

Microprocessor-based instrumentation

Functions of the optional software: educational software, data acquisition, system operation

Software for data acquisition via USB under Windows 7, 8.1, 10

Technical Specifications

Heater

Heating power 30W

Temperature limitation: 160°C

6x fan

Max. flow rate: 40m3/h

Nominal speed: 14400min-1

Power consumption: 7,9W

4x samples, short

Length dissipating heat: 104mm

Heat transfer area: 32,6cm2

Copper, aluminum, brass, steel

2x samples, long

Length dissipating heat: 154mm

Heat transfer area: 48,4cm2

Copper, steel

Measuring ranges

Flow velocity: 0…10m/s

Temperature: 8x 0…325°C

Heating power: 0…30W

Experiments

Effect of heat conduction and convection on heat transfer

Effect of free and forced convection on heat transfer

Calculate convective heat transfers

Effect of different materials on heat conduction

Effect of sample length on heat transfer

Requirements

Mains Power 220 – 240V @ 50Hz, 1Ph

91-9829132777

91-9829132777