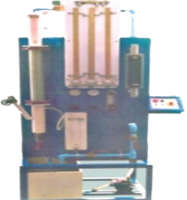

Emulsion Polymerisation Set-Up

Order Code: 14179

Category: Chemical Reaction Engineering

Introduction: The set-up is used to carry out the emulsion polymerization involving polymerization of a unsaturated monomer like Styrene. Emulsion is of the type: oil in water, monomer is oil soluble & the initiator is water-soluble & an emul...

SPECIFICATION

Introduction: The set-up is used to carry out the emulsion polymerization involving polymerization of a unsaturated monomer like Styrene. Emulsion is of the type: oil in water, monomer is oil soluble & the initiator is water-soluble & an emulsifier is used to create a stable emulsion.

Specifications:

- Reactor:Material Stainless Steel, Total volume of Reactor 1.5 - 2 Ltrs. (approx.)

- Agitator : Material Stainless Steel Impeller (2 paddles) fitted with Stainless.Steel Shaft coupled to DC Motor with Thyristor controlled DC Drive.

- Flow Measurement:Rota meter for Nitrogen Gas.De-Oxygenation Column : Compatible capacity.

- Hot Water Tank: Material Stainless Steel, Double Wall, insulated with ceramic wool.

- Hot water circulation: Magnetic Pump made of Polypropylene. Maximum working temperature is 80°C.

- Heaters: Nichrome wire heater.Initiator Reservoir:Capacity 25-50.

- Temperature sensors : RTD PT-100 type 5 Nos.

- The whole set-up is ingeniously designed and schematically arranged on a powder-coated rigid structure.

91-9829132777

91-9829132777