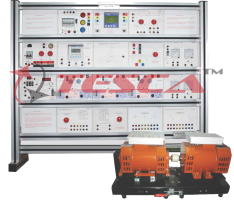

Electrical Installation & Wiring Practice Booth

Order Code: 46979

Category: Electrical Machine Lab

Many important details must be observed in order to succeed in educating the electrical installation. These details can be different from place to place depending on local installation rules, installation systems, the background and levels of trainee...

SPECIFICATION

Many important details must be observed in order to succeed in educating the electrical installation. These details can be different from place to place depending on local installation rules, installation systems, the background and levels of trainees training.

List of Experiments

A few of the points that are common in most training situations should be taken into account:

- Before training targets are defined clearly Any training to start.

- Electrical regulatory requirements must Be observed.

- Safety and Security shall be an integral training component.

- The curriculum planning and actual practical breakdown and there must be completed theoretical projects.

- The equipment and materials used must be standards, strong to resist heavy treatment beginners have compiled the training in such a way follows and should follow a pedagogical sequence. As far as possible, normal installation practice follow.

- Training monitoring and storage These factors include type of building construction, type of ceiling, wall and floor construction, wiring methods, installation requirements, etc. Wiring booth will build/boost the technician’s confidence to a level that he/she can go and work on their own without any hesitations in terms of wiring and device knowledge.

The electrical installation booth is designed to give real-time hands on practice to students using standard electrical devices such as switches, distribution boards, sockets, Contactors, MCB, ELCB, and light fittings in a structure.

I. Wiring Practice Module

- The Electrical Installation module will teach the fundamental training concepts of electrical wiring of Different scenarios. The Module will enable trainees to learn/install methods of both conventional and latest Wireless Technology devices (IOT enables).

- Student will be able to understand the following points

- Installation plans, handling non-metallic cable,

- Connecting electrical services,

- Installing basic electrical components like Switches, outlets, and lighting,

- Electrical component symbols and wiring,

- A storage case for loose components, and a hand tool package.

- Combination of real-world components and hands-on electrical wiring training allows learners to practice skills they will use on the job, such as

- Wire stripping and termination techniques

- Grounding methods used in junction boxes

- Installing a circuit breaker in a service panel Setup will have an individual practice module with all the required accessories/components with minimum following specifications.

- Conduit sample kit with five types of conduit. Learners will study industry-relevant skills including how to prepare, cut, bend, and connect conduit, handle advanced raceways, and select wire sizing and types. The system has use industrial quality components to help learners become better prepared for what they will encounter on the job as well as to withstand frequent use.

- Learners study install a variety of conduit types, size fuses, install bus plugs, and connect motors. Learners should know and study how safely they handle 3-phase power. Safety devices, such as safety Smart Switches and lockout/ tagout locks, help learners to develop the safety skills needed to assure safe operation in an industrial environment.

II. Conduit module

Conduit module consist of following items (consumables)Installation practice using conduit in concealed conditions, complimented with different wiring circuits including intermediate Wireless controlled Switching and socket circuits. Learning of Electrical Devices and Web Integration to create a Central Web/Mobile Dashboard to Monitor.

The Module should consists of:

- 10 m Cable REV 3×1.5 mm sq

- 50 m Conduit cable FK 1 x 1.5 mm sq, white

- 50 m Conduit cable FK 1 x 1.5 mm sq, black

- 50 m Conduit cable FK 1 x 1.5 mm sq, blue

- 50 m Conduit cable FK 1 x 1.5 mm sq, yellow/green

- 100m Conduit pipe 20mm

- 50m Conduit pipe 25 mm

- 15m Conduit pipe 32 mm each.

- 16pcs Galvanised Steel Rigid Conduit Metal 20mm x 3.75m M20 x 1.5mm

- 50 pcs Junction box different size each 10pcs

- 9 pcs Terminal mounting box

- 50 pcs Blanking plates different size

- 100 pcs Cable connectors

- 30 m PVC tubing flexible, approx. 15 mm dia. Etc.

System Includes

Installation instruction manual incl. Installation plan with wiring diagram.

- Components/material box

III. Surface Wiring module

To be used for developing skills in clipping, bending and setting of surface mounted wires and cables, making circuit connections from a fuse experiment panel to single and three phase outlets, circuit breakers, controllers, etc. Integrating and Controlling Starters, MCBs, Switches to a Web Dashboard with wireless enabled devices.

The kit consists of

- 1 pc Distribution panel,

- 1 pc Main smart switch

- MCB 10 A 1-pole 10MCB’s

- 1 pc Motor starter

- 2pcs circuit breaker 2pole

- 2 pcs contactor 3pole

- 1pcs Over load relay

- 1 pc Push button control box

- 1 pc Safety Switch

- 5pcs 3-phase outlet

- 1 pc Direct-on-line starter manual,

- 1 pc Plastic bin

The Setup includes instruction manual incl.

Installation plan with wiring diagram.Components/material box.

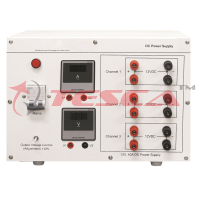

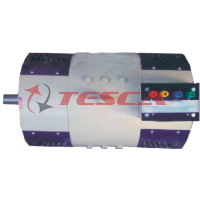

IV. Three-phase industrial module

A three-phase system will be connected to the mains supply via a starter, fuse board, earth leakage circuit breaker and kWh IoT Smart meter. PVC surface cable is used throughout except for the connection between the motor and terminal box where flexible conduit PVC single cable is used. Direct on line, manual, star delta and automatic star delta staring can be connected into the circuit. Isolated earthing is necessary on the motor circuit for correct operation of the ELCB.

The module consists of

- 1 pcs PLC module. (Power supply, wires, Din rail, terminal box)

- 1 pc 3-phase AC motor with Fault Monitoring System

- 1 pc Distribution panel complete with three MCB 10 A 1-pole and main Switch

- 1 pc kWh-Smart energy meter, 3-phase –

- 1 pc Motor starter / overload relay with contactor

- 3 pcs circuit breaker 1pole

- 1 overload relay three phase

- 200 pcs Clips TC 4,6,7,10,20 and 25 each (1200)

- 100 pcs Wood screws (4 x 16)

- 90 m wire 1.5 mm sq, black

- 90 m wire 1.5 mm sq, Red

- 90 m Wire 1.5 mm sq, yellow/green

- Limit switch

- 50 m Conduit cable FK 1 x 1.5 mm sq, white

- 50 m Conduit cable FK 1 x 1.5 mm sq, black

- 50 m Conduit cable FK 1 x 1.5 mm sq, blue

- 50 m Conduit cable FK 1 x 1.5 mm sq, yellow/green

- DC24V switching power supply

- 1 pc Plastic bin.

The Setup includes instruction manual including Installation plan with wiring diagram, Components/material box

V. Lighting module

To be used for the trainees to practice in wiring of lighting control circuits with differet types of models . Two lighting control circuits are incorporated in this module.

The Module consists of

- 2 pc Pushbutton box with contactor

- 1 pc Distribution panel

- 6 pcs MCB, 10 A, 1-pole

- 1 pc Photo cell operated relay

- 1 pc Staircase relay

- Junction box 2,3 & 4 way each 5Pcs (15)

- 2Pcs DP switch

- 10pc, Switch 2-way

- 100 m Cable 3 x 1.5 mm sq.

- 25 m Cable 45 x 1.5 mm sq.

- 180 m wire 1.5 mm sq, black (2coil)

- 180 m wire 1.5 mm sq, Red (2coil)

- 180 m Wire 1.5 mm sq, yellow/green (2coil)

- Thermal Relay

- 50 m Conduit cable FK 1 x 1.5 mm sq, white

- 50 m Conduit cable FK 1 x 1.5 mm sq, black

- 50 m Conduit cable FK 1 x 1.5 mm sq, blue

- 50 m Conduit cable FK 1 x 1.5 mm sq, yellow/green

- 5 pc Main cable

- 2 pcs Fluorescent lamp holder with choke and Starter Timer Relay, Etc.

- The Setup includes instruction manual incl. Installation plan with wiring diagram.

- 3 pcs Junction box – wireless IoT Enabled Smart, Smart Switch Box with 2 Relay for Manual and Cloud based Control of Lights (Frequency: 865 – 867MHz) with Web App & Mobile App

- 2 pcs Fluorescent lamp holder with choke and starter

- Timer Relay

- 5 pcs Fluorescent lamps

- Lamp holder 3 different types 5 pcs each

- 2 pcs Bulb

- 5pcs CFL

- emergency button

- 5pcs LED bulb Different wattages.

- 200 pcs Clips TC 7-10

- 100 pcs Wood screws (4 x 16)

- 100 pcs Wood screws (4 x 25)

- 10mtr DIN rail

- 1 pc Plastic bin

System Includes

Installation instruction manual incl. Installation plan with wiring diagram.

- Components/material box.

VI. Residential module

Residential module for instruction in principles and schematic diagrams of electric wiring in apartments/home. The setup should consist of complete modules, representing a typical floor plan of an apartment/home. The setup utilizes, as much as technically possible, full size electrical components as Smart Switches, circuit breakers, receptacles, light fixtures and lamps. Supply voltage: 24V AC, 3-phase system from an overload protected power supply, simulating a 220-240V 3-phase system. The module equip with an energy Smart meter. Complete with:

Set of components to meet residential wiring curriculum requirements.

- Wire package set

- Hand tool set necessary for wiring.

- Student Work Book.

- Laboratory manual describing residential wiring fundamentals such as:

Module Consists of

- 5 m Cable REV 5 x 2.5

- 50 m conduit cable Cable FK 1.5, black

- 50 m conduit Cable FK 1.5, blue

- 50 m conduit Cable FK 1.5, brown

- 50 m conduit Cable FK 1.5, yellow/green

- 180 m wire 1.5 mm sq, black (2coil)

- 180 m wire 1.5 mm sq, Red (2coil)

- 180 m Wire 1.5 mm sq, yellow/green (2coil)

- 5 pc Junction box

- 8 pcs Terminal mounting box

- 100 pcs Cable connectors

- 50 m PVC tubing flexible

- 20 Pc One way switch

- 15 PC two way switch

- 1 pc Smart Switch, one way, double pole

- 5 pcs Smart Switch, two way (stair case)

- 20pc Wall socket, two way, no earth

- 100 pcs Wood screws (4 x 16)

- 100 pcs Wood screws (4 x 30)

- 1 pc Distribution Panel. Etc,

Assembly Frame

The setup should be Easily assembled and disassembled format. Can be free standing or fixed to the floor or to a work bench. Setup should have sliding facility for the pine board to assemble and disassembled.

Plasterboard, chipboard or Pine wood can be fitted to this frame providing total thickness is not more than 16-19 mm. The T-shaped assembly takes 3 boards each of the area 1200 x 2400 mm.

Assembly Boards

- Chipboard Set of 3

- Dimensions 1200 x 2200 x 22 mm (each board)X3 Boards

91-9829132777

91-9829132777