Electrical connection of refrigerant compressors

Order Code: 24258098.69

Category: General Lab Equipment V

Electrical connection of refrigerant compressors Use of a real refrigerant compressor Features correct electrical connection of a refrigerant compressor use of a real refrigerant compressor design and investigation of a safety chain ...

SPECIFICATION

Electrical connection of refrigerant compressors

Use of a real refrigerant compressor

Features

- correct electrical connection of a refrigerant compressor

- use of a real refrigerant compressor

- design and investigation of a safety chain

Specification

- experimental unit from the practical series for the training of mechatronics engineers for refrigeration

- correct electrical connection of a refrigerant compressor

- refrigerant circuit with compressor, receiver, 2 valves and 2 manometers to investigate pressure switches on the delivery and intake sides

- electrical components for the start and operation of the compressor mounted clearly visible

- lab jacks and cables to connect the electrical components

- operation of a thermostat

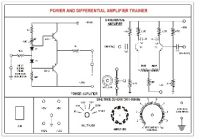

- circuit diagram on the front panel for easy identification of the components

- refrigerant R513A, GWP: 631

Technical data

Refrigerant compressor

- power consumption: approx. 193W at 5/55°C

- refrigeration capacity: 374W at 5/55°C

Receiver: 0,8L

Manometer measuring ranges

- delivery side: -1...24bar

- intake side: -1...9bar

Pressure switch control range

- delivery side: 8...32bar

- intake side: -0,9...7bar

Thermostat: -5...35°C

Electrical components for the compressor

- start-up capacitor

- start-up relay

- overheat protection (bimetallic)

- automatic fuse

Refrigerant

- R513A

- GWP: 631

- filling volume: 300g

- CO2-equivalent: 0,2t , 230V, 50Hz, 1 phase

Electrical faults in refrigerant compressors nvestigation of important electrical components from refrigeration

Features

- real refrigerant compressor from practice

- investigation of important electrical components from refrigeration

- simulation of 15 faults

- Learning objectives/experiments

- electrical connection of refrigerant compressors

- read and understand electrical circuit diagrams

- design and operation of the electrical components of a refrigerant compressor

- o start-up capacitor

- o start-up relay

- o operating capacitor

- o overheat protection

- o main contactor

- o automatic fuse

- fault finding in electrical components

- o in idle state

- o under mains voltage

Specification

- experimental unit from the practical series for the training of mechatronics engineers for refrigeration

- investigation of the electrical components for the operation of a refrigerant compressor

- real refrigerant compressor from practice

- electrical components for the start and operation of the compressor arranged in the transparent switch cabinet

- general safety devices mounted clearly visible

- circuit diagram depicted on the front panel

- identification of 15 faults: multimeter measures voltages or resistances at the lab jacks

- refrigerant R449A, GWP: 1397

Technical data

Refrigerant compressor

- power consumption: approx. 870W Electrical components for the compressor

- start-up capacitor

- start-up relay

- operating capacitor

- overheat protection (bimetallic)

General safety devices

- main contactor

- automatic fuse

Refrigerant

- R449A

- GWP: 1397

- filling volume: 80g

- CO2-equivalent: 0,1t , 230V, 50Hz, 1 phase

91-9829132777

91-9829132777