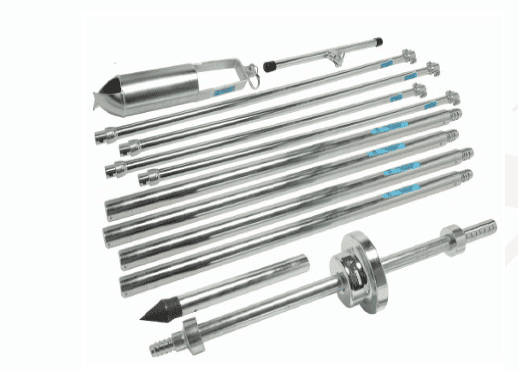

Dynamic Cone Penetrometer Set

Order Code: 24258372.1

Category: General Lab Equipment V

Dynamic Cone Penetrometer Set Background The Standard Penetration Test (SPT) is an empirical method used to measure soil resistance by counting the number of blows required to drive a casing into the ground. For situations where mechanized SPT ...

SPECIFICATION

Dynamic Cone Penetrometer Set

Background

The Standard Penetration Test (SPT) is an empirical method used to measure soil resistance by counting the number of blows required to drive a casing into the ground. For situations where mechanized SPT devices are impractical—such as in confined spaces or for expedient testing—miniaturized versions of the SPT have been developed for hand-operated tools, especially for shallow depths.

In 1959, Professor George Sowers introduced one of the most widely used devices for field exploration and evaluating lightly loaded shallow spread footings. For more in-depth information, please refer to the following reference:

-

George F. Sowers and Charles S. Hedges, "Dynamic Cone for Shallow In-Situ Penetration Testing, Vane Shear and Cone Penetration Resistance Testing of In-Situ Soils," ASTM STP 399, American Society for Testing and Materials, 1966, p. 29.

The Dynamic Cone Penetrometer (DCP), as illustrated in Figure 1a, employs a 15 lb steel mass that falls 20 inches to strike an anvil. This action causes a 1.5-inch diameter, 45-degree cone to penetrate into the soil at the bottom of a hand-augered hole. It has been particularly useful in the Southeastern USA, where it has been calibrated with standard SPT results. The original correlations by Sowers are shown in Figure 1b. Similar correlations can be developed for soils in different regions based on their geological origin.

Operating Instructions

-

Test Location:

-

Perform the penetration test at the bottom of a hand-augered hole, typically with a diameter of 3 to 6 inches.

-

-

Augering:

-

Auger to the desired depth, ensuring as much of the bottom cuttings are removed as possible. These auger cuttings can also be used to visually classify the soil.

Warning: Handle the Dynamic Cone Penetrometer (DCP) carefully. Avoid grasping the rod between the pull-out anvil and the driving anvil, as the 15 lb sliding weight moves easily along this section of the rod.

-

-

Lower the Equipment:

-

Carefully lower the sliding drive hammer, extension rods, and drive point to the bottom of the borehole.

-

-

Set the Cone:

-

Ensure the assembly is plumb and place the cone 2 inches into the undisturbed bottom of the hole to ensure full cone embedment.

Tip: To speed up measurements, lay a flat straight edge (e.g., a survey stake) across the borehole and mark a reference point for easy measurement.

-

-

Driving the Cone:

-

Maintain the assembly in a plumb position and drive the cone down 1-3/4 inches (44mm) by allowing the ring weight to free fall from a height of 20 inches. Ensure that the ring weight reaches the uppermost position against the pull-out anvil to guarantee a 20-inch drop.

-

Count and record the number of blows required to achieve the 1-3/4 inch (44mm) penetration.

-

-

Subsequent Penetrations:

-

Optionally, perform a second and third penetration test by driving the cone an additional 3/4 inch (44mm) per test. Beyond three increments, shaft friction may influence results.

-

-

Remove the DCP Assembly:

-

Carefully remove the DCP assembly from the borehole, keeping hands clear of the anvil and sliding weight.

-

-

Repeat Testing:

-

Auger to the next test location and repeat steps 3 through 7.

Note: The DCP is effective for use in augered holes up to depths of 15 to 20 feet. Beyond these depths, handling the rod assembly manually becomes cumbersome. Additionally, the correlations for deeper depths have not been verified due to potential energy losses from thread joints and rod inertia.

-

Drive Tube Accessory

The Cone and Adapter Rod Assembly can be replaced with the H-4202.7A Drive Tube Assembly, which is used for collecting 3 x 10" tube samples (H-4202.10) in augered holes.

91-9829132777

91-9829132777