Diesel Engine Control System CR/EDC 15

Order Code: AT0003

Category: Automotive Trainers

Description Fully functional system Diagnosis through OBD 16 pole diagnostic socket Open contacts for measuring system components and circuits Fault code simulations Common Rail trainer with engine control sys...

SPECIFICATION

Description

-

Fully functional system

-

Diagnosis through OBD 16 pole diagnostic socket

-

Open contacts for measuring system components and circuits

-

Fault code simulations

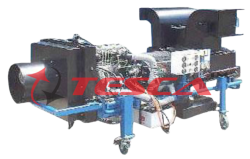

Common Rail trainer with engine control system Bosch EDC 15C3-4.1 is installed in a mobile aluminum frame. This training board-simulator is specially designed to help technical students understand the system of diesel injection Common Rail.

The educational training board is based on Renault's OEM components. The integrated engine control system Bosch EDC 15 shows the different operation modes of the direct fuel injection system. Common Rail training board-simulator is a great educational tool that allows students to learn the structure of engine control system, study its components and operation modes, perform various measurements, tests, and other diagnostic procedures. For technical and vocational Tesca education and training.

Technical Specifications and Functions

-

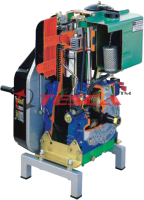

Integrated engine control system with diesel Common Rail direct injection

-

The stand consists of two parts: one is designed to demonstrate the work of the high pressure pump and injectors, the other to demonstrate the electronic engine management system; Both parts are electrically interconnected and operate as a single system

-

Monitoring operation of high pressure fuel supply system, injected fuel quantity, the amount of fuel back leak, spray pattern quality

-

The adjustable air flow rate simulator demonstrates the function of the mass air flow meter and air temperature sensor

-

Manual adjustment of the engine crankshaft speed

-

Integrated simulators allow changes of the parameters of the engine temperature sensor Integrated simulators allow changes of the parameters of the intake air pressure sensor

-

Electric wiring diagram with built-in banana plug jumpers for measurements and simulation of system fault codes

-

Ability to monitor the changing operation mode of each system component

-

Possibility to simulate more than 20 faults by disconnecting Banana plug jumpers

-

Integrated TFT voltmeter displays voltage of electronic system component:

-

APPS1 Accelerator pedal position sender I

-

APPS2 Accelerator pedal position sender II

-

ACT Air charge temperature sensor

-

MAF Air-mass flow meter

-

FPS Fuel high-pressure sensor

-

MAP Intake manifold pressure sensor

-

EGR Exhaust gas recirculation potentiometer

-

CTS Engine coolant temperature sensor

-

FTS Fuel temperature sensor

Diagnostic and Measurement

Oscilloscope/Multimeter

System's parameters are measured by connecting to the banana connector

Ability to measure electrical signal parameters of each system component (such as sensor or actuator) Control unit diagnosis

Diagnosis through OBD 16-pin diagnostic connector

-

Electronic control unit (ECU) identification

-

Reading/erasing fault codes

-

Displaying the operating system parameters (live data) Activating the actuators (depends on the control unit)

-

Control unit encoding/configuration

Other

The stand has a closed structure - internal wiring is not visible

-

Power supply: 220/12 V

-

Dimensions approx.: (HxLxW)

-

Electronic part (board) 1820 x 1360 x 500 mm

-

Mechanical part (trolley) 1500 x 800 x 500 mm

-

Nett weight approx.: 135 Kg

-

CE certificate

Optional Accessories

-

Examination console for 10 hidden fault simulations

-

Tesca oscilloscope

-

OBD diagnostic scan tool

Tesca training equipment is a great tool for professional teachers and technicians that helps explain to students of technical subjects how processes in Diesel engine control system CR/EDC 15 operate and its technology.

91-9829132777

91-9829132777