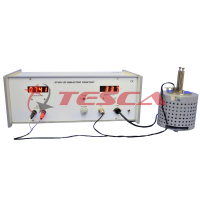

Dielectric Measurement Setup

Order Code: 55525E

Category: Physics Trainers

Introduction Beside the common and well known application of capacitors in electrical and electronic circuits, the capacitors with an exposed and porous dielectric can be used to measure humidity in air. A huge leap in the research...

SPECIFICATION

Introduction

Beside the common and well known application of capacitors in electrical and electronic circuits, the capacitors with an exposed and porous dielectric

can be used to measure humidity in air.

A huge leap in the research on dielectrics (ferroelectric materials) came in 1950's, leading to the wide spread use of ceramics in capacitor applications and piezoelectric transducer devices. Since then, many other ferroelectric ceramics have been developed and utilized for a variety of applications: various type of capacitors, nonvolatile memories in computers, etc.

Features

LCD Display

Data - Hold Switch (HOLD)

Cx , Cx - Input Jack

Back Light Button Switch

Rotary Switch: Use this switch to select functions and ranges

Wide measuring range, covering 9 measuring sections from 0.1pf to 20,000μF that includes nominal value of any capacitance

Power: One 9V battery

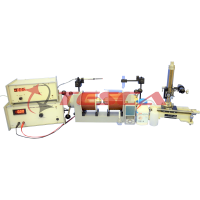

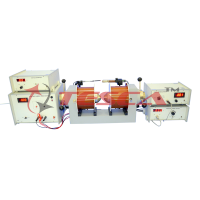

Description of the Experiment Set-up

1. Probes Arrangement

It has two individually spring loaded probes. The probes arrangement is mounted in a suitable stand of high quality alumina which also holds the sample plate. To ensure the correct measurement of sample temperature, the thermocouple junction is embedded in the sample plate just below the sample. This stand also serves as the lid of temperature controlled oven.

Proper leads are provided for connection to Capacitance Meter and Temperature Controller.

2. Sample

Modified lead titanate (test sample)

3. Oven

This is a high quality temperature controlled oven. The heating element used is a high grade Kanthal-D. It is cover. Further the top portion is also suitably covered to meet the safety standard. The oven has been designed for fast heating and cooling rates, which enhances the effectiveness of the controller.

4. Main Units

The Set-up consists of two units housed in the same cabinet.

(i) Temperature Controller

It is a high quality PID controller where the temperatures can be set and controlled easily. P, I and D can be adjusted by the user and can also be kept on Auto-tuning.

Specification

Temperature Range : Ambient to 600° C

Power Supply : 100-240VAC; 50/60Hz

Display Method : 7 Segment LED display [Processing value (PV)

: Red, Setting value (SV): Green]

Input Sensor : Thermocouple (Chromel - Alumel)

Control Method : PID, ON/OFF Control, P, PI, PD, PIDF, PIDS

Display Accuracy : ± 0.3%

Setting Type : Setting by front push bottons

Proportional Band (P) : 0 to 100.0%

Integral Time (I) : 0 to 3600 Sec

Derivative Time (D) : 0 to 3600 Sec

Sampling Time : 0 to 120 Sec

Sampling Time : 0.5 Sec

Setting (P, I & D) : Manual / Auto

91-9829132777

91-9829132777