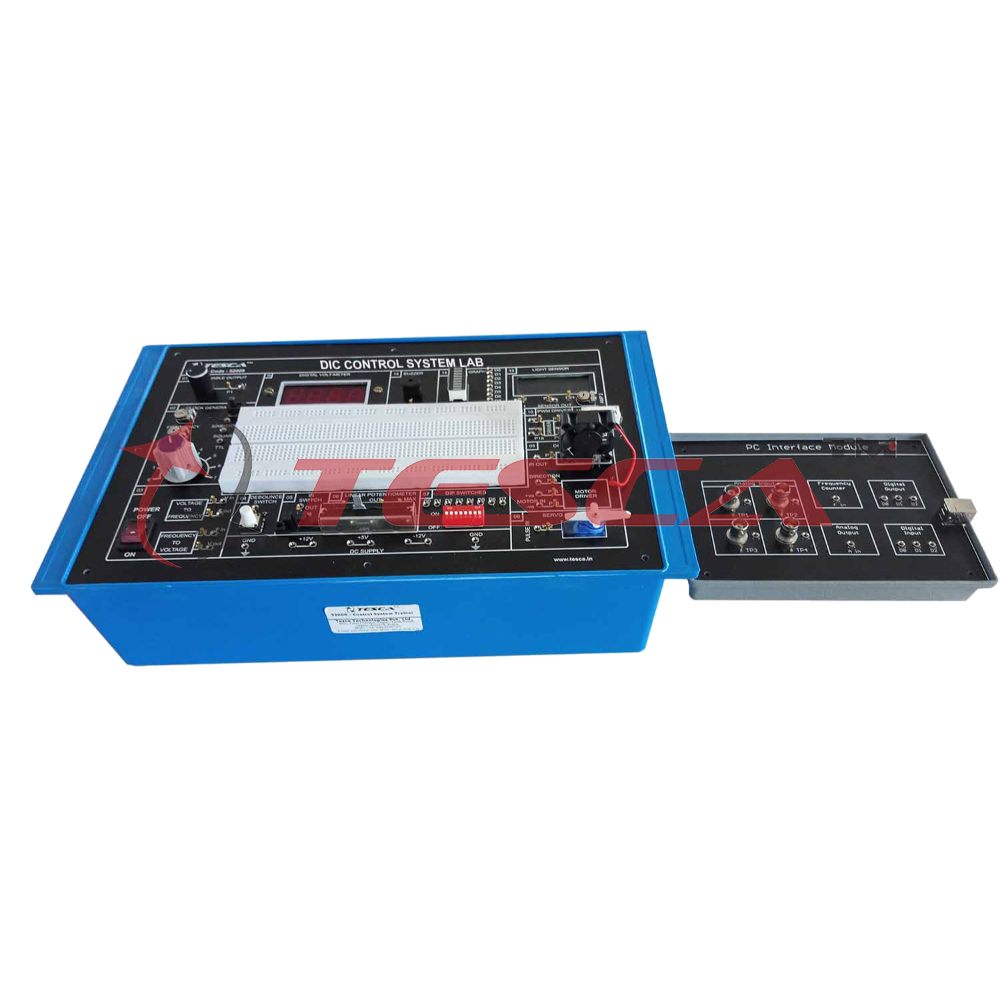

DIC Control System Lab

Order Code: DIC-6901

Category: DIC Lab

DIC Control System Lab explores students & industry professional to the fundamentals of digital imaging correlation Control System. It demonstrates, how one device can be used to manage, command, direct or regulate the behavior of other system. S...

SPECIFICATION

DIC Control System Lab explores students & industry professional to the fundamentals of digital imaging correlation Control System. It demonstrates, how one device can be used to manage, command, direct or regulate the behavior of other system. Sequential Control, Linear Control is also well explained in the trainer.

DIC Control System Lab has sensors like Vibration, Thermal imaging, Temperature sensor, Light sensor, DC motor, Filament lamps, IR sensor and many more which can be used for the study of Control system. There is a wide range of experiments which can be performed on the trainer. Application software for Interfacing with PC increases range of experiments.

Features:

01. FEA Validation

02. Temperature Control

03. Feedback concept

04. On board DC supply

05. Open loop Control system

06. DC motor control

07. Speed control

08. Close loop Control system

09. Servo motor control

10. Light intensity control

11. V/F & F/V conversion

12. LED bar display

13. Bread board for circuit design

14. User can design & develop own circuits

15. PC interface for open loop & Close loop control

16. PC based Frequency counter

17. PC based DC voltmeter

18. Real time graphical representation

19. User friendly software

20. Exhaustive course material & references

Technical Specifications:

DC Motor : 12 VDC

Servo Motor : 5 VDC

Temperature Sensor : 10 mV / ° C

Light Sensor : Photo Conductive Cell (LDR)

Light Source : Two numbers of filament lamps

V/F : For 0 - 5 V output is 0 -50 KHz (approx.)

F/V : For 0 - 50 KHz output is 0 - 5V (approx)

PC based Analog Inputs : 4 Inputs with 0 to 5 V / 0 to 10 V

PC based Analog Output : 1 Output with 0 to 5 V / 0 to 10 V

PC based Digital Inputs : 3 Inputs

PC based Digital Outputs: 3 Outputs

PC based DC Voltmeter : 0 to 10 V range

PC based Frequency counter : 0 to 6 MHz (square wave)

DPM : Rang 0-20 Vdc

De-Bounced Switch : Monostable (5 V output)

Buzzer : 5 Voperated

Switches : IR Switch, DIP selector switch

Clock : 0-50 KHz (approx)

Power Supply : 230 V ±10%, 50 Hz

Power Consumption : 4 VA(Approx)

Test Points : 28

Dimension (mm) : W 365 D 265 H 120

Weight : 4 Kg (approx)

Experiments

* To study and observe Voltage to Frequency converter

* To study and observe Frequency to Voltage converter

* To study and implement Light intensity control using PWM method

* To study and observe Characteristics of Photoconductive Cell (LDR)

* To study and implement Motor speed and input characteristics

* To study and implement Bidirectional motor speed control

* To study and implement tachogenerator using F/V converter

* To study and implement Motor control using PWM method

* To study and observe Position control of DC Servo Motor

* To study and implement DC Motor Control-Open Loop

* To study and observe DC Motor Control-Close Loop

* To study and implement Temperature Control-Open Loop

* To study and observe Temperature Control-Close Loop

* To study and implement Light intensity Control-Open Loop

* To study and observe Light intensity Control-Close Loop

Accessories Include :

1. Patch Cord 8” ( 2 mm to 1 mm ) 4 nos.

2. Patch Cord 12” 8 nos.

3. 5 Pin DIN cable 1 no.

4. PC Interface Module 1 no.

5. Software CD 1 no.

6. Mains Cord 1 no.

7. Operating Manual 1 no.

8. Dust Cover 1 no.

91-9829132777

91-9829132777