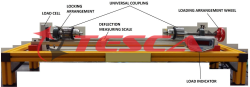

Critical Speed Investigation Apparatus

Order Code: 32144

Category: Strength of Materials Lab

Features Investigation of bending vibrations in rotors Determining critical speeds Position of rotor mount and rotating mass can be adjusted Optimal visibility and simultaneous protection thanks to transparent protective cover ...

SPECIFICATION

Features

- Investigation of bending vibrations in rotors

- Determining critical speeds

- Position of rotor mount and rotating mass can be adjusted

- Optimal visibility and simultaneous protection thanks to transparent protective cover

At a certain speed the imbalance forces of a rotating mass can cause part of the machine or the entire machine to vibrate in resonance with bending vibrations. This speed is known as the critical speed. The rotor and shaft on a motor or a turbine, for example, form a system that can resonate. In rapidly rotating machinery this state presents a danger because it can lead to breakage and damage to the components of the system. To prevent this, the system is operated well above or below the critical speed and quickly driven through the critical speed range. Structural changes, e.g. changes to rigidity, can cause the critical speed to change, meaning the operational requirements have to be adapted.

Critical Speed Investigation Apparatus 32144 experimental unit teaches knowledge about how to determine the critical speeds. Illustrative experiments are used to explain resonance and supercritical or subcritical states of a vibrating system.

A three-phase motor drives a rotor shaft, onto which one or two masses may be fixed at various distances. The rotor shaft is mounted in two self-aligning ball bearings and connected to the motor via a flexible coupling. The electronically regulated speed can be selected via two potentiometers and is continuously variable. It is displayed on a digital readout by a revolution counter. The position and distances to elements fixed onto the rotor shaft can be read on a scale mounted in parallel to the rotor shaft.

A transparent protective cover and safety bearing immediately next to the masses attached to the rotor shaft ensure safe operation.

32144 Critical Speed Investigation Apparatus Model 021 accessory comes with measurement and evaluation software, including sensors, for data capture via PC. Alternatively, the TM 620.01 accessory can be used together with for data acquisition.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specifications

- Investigation of bending vibrations and resonance of a rotating system

- Two self-aligning ball bearings moveable to any point as the rotor shaft mount

- Two masses that can be fixed at any point

- Safety bearing and transparent protective cover for safe operation

- Two pre-selectable speed ranges, speed electronically regulated and infinitely adjustable

- Digital speed indicator

- Two options for data acquisition: either vibration sensors with supply unit for connection to an oscilloscope or data acquisition system including software and sensors

Technical Specifications

Three-phase motor

- Power 0,25kW

- Max. speed 3000min-1

Rotor shaft

- L=500mm

- D=6mm

- Hardened steel

2x mass, disc-shaped

- m=965g

- D=80mm

- Hardened steel

Shaft mount

- 2x self-aligning ball bearings

- 2x safety bearings

Measuring ranges

- Speed: 300...3000min-1

- Scale for measuring distance: 0...500mm

Experiments

- Investigation of bending vibrations and resonance of a rotating shaft

- Determination of critical speeds with different arrangements of the bearing and masses on the rotor shaft

- Investigation of the rotor shaft's self-centering effect

Scope of Delivery

1 Experimental set up, complete

1 Set of instructional material

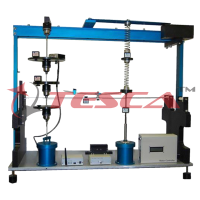

Sensor Supply Module Order Code - 32144SS

Features

- Supply and measured data conditioning for the vibration sensors

Sensor Supply Module 32144SS is used to provide power to vibrations sensors. The module provides the necessary power and outputs the corresponding measured signals. Up to four sensors can be connected simultaneously using 7-pole DIN sockets. The analogue measured signals in the range from 1...9 Volts are output on 4mm lab jacks and can be displayed on a measuring instrument or an oscilloscope.

The unit has a robust steel sheet housing with anti-slip rubber feet.

Specifications

Unit for supplying power and conditioning measured data from inductive vibration sensors

Up to 4 sensors can be connected simultaneously

Technical Specifications

Signal output

- Voltage: 1...9V

- Output on 4mm lab jacks

Scope of Delivery

1 sensor supply module

1 manual

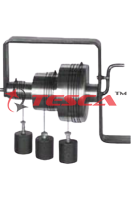

Vibration Sensors with Clamping Set

Order Code - 32144VS

Features

- Non-contact inductive position sensors

- Optimal tool to record vibrations

The displacement of the rotor shaft studied in the experimental units for measurement of electronically using the sensors The measuring principle based on induction works contactless and operates therefore without feedback. The measured values are not influenced. The output signal of each sensor is an analog DC voltage signal proportional to the position respectively displacement of the rotor. Clamping elements for the sensors are included.

The additionally required sensor supply module supplies up to four of these sensors and processes their signals. An oscilloscope is most suitable to display the signals.

Specifications

- Accessory for 32144

- 2 position sensors, non-contact, to measure the displacement of rotors without influencing measured values

- Analog signal output proportional to the rotor displacement

- Display of measuring signals on external oscilloscope

- Clamping devices included

- Wrench span for assembly: 36mm

- Sensor supply via the sensor supply module 32144SS

Technical Specifications

Position sensor

Measuring principle: inductive, non-contact

Operating range: 5...10mm

Frequency range: 0...50Hz

Output signal: 1...9VDC proportional

Scope of Delivery

2 sensors with cable

2 sensor clamps

1 set of small parts

1 manual

91-9829132777

91-9829132777