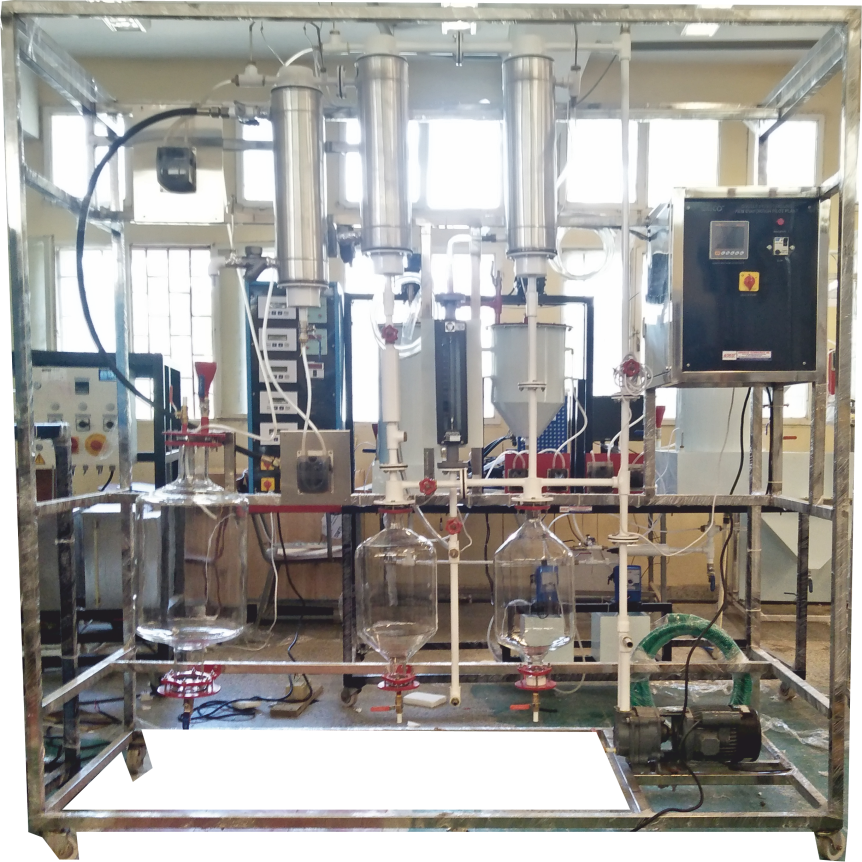

Continuous Distillation Pilot Plant

Order Code: 14238

Category: Mass Transfer Lab

Introduction: The solution having to be distilled, stored in a glass tank, is sent to the distillation column by a metering pump after crossing a pre-heating exchanger. The column can be fed through 3 points at different height. The distillation colu...

SPECIFICATION

Introduction: The solution having to be distilled, stored in a glass tank, is sent to the distillation column by a metering pump after crossing a pre-heating exchanger. The column can be fed through 3 points at different height. The distillation column is completely made of glass and it consists of a reboiler, of a column with packing of steel mesh and of a condenser with reflux valve and head. The bottom product and the distillate are collected into two glass tanks after being cooled by two heat exchangers.

Specifications: Framework of stainless steel with castors 15 l feeding tank of borosilicate glass Distillation column of borosilicate glass, h = 1100 mm, packed with mesh of 316 stainless steel Reflux head of borosilicate glass equipped with solenoid valve for the control of reflux ratio Reboiler of borosilicate glass, with capacity of 5 l, equipped with quartz-sheathed electric heater of 2.5 Kw Over head condenser of borosilicate glass, with exchange surface of 0.4 m2. 2 graduated vessels of borosilicate glass for collecting the bottom product (4 l) and the distillate (1 l) Tube-in-tube heat exchanger of stainless steel for the bottom product Feeding metering pump of 316 stainless steel, with max. flow rate of 12 l/h Flowmeter of 304 stainless steel for measuring the flow rate to the condenser, range of 0 to 250 l/h 2 programmable timers for the control of reflux ratio 12 thermoresistances Pt 100, with sheath of 316 stainless steel 2 electronic temperature indicators Electronic differential pressure transmitter (between column top and bottom) of 316 stainless steel, with range of 0 to 200 mm H2O, 4-20 mA output signal Quartz-sheathed electric heater for preheating the feeding mixture, P = 0.3 kW Piping and valves of 304 and 316 stainless steel Control Panel Emergency button.

91-9829132777

91-9829132777