Cascade Control (Flow - Level) Trainer

Order Code: 52240

Category: Process Control Trainers

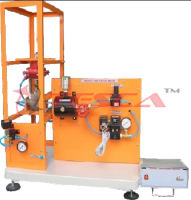

The Cascade Control Trainer is the system, which outlines the basics of Cascade Control considering Flow, Level parameters. KEY WORDS: Feedback Control. ON-OFF & PID control. OPEN/CLOSE loop response. MANUAL/AUTO tuning o...

SPECIFICATION

The Cascade Control Trainer is the system, which outlines the basics of Cascade Control considering Flow, Level parameters.

KEY WORDS:

- Feedback Control.

- ON-OFF & PID control.

- OPEN/CLOSE loop response.

- MANUAL/AUTO tuning of controller

- Cascade Control (Flow +Level)

- Feedback Flow Control.

- Feedback Level Control

- PID control: P, P+I, P+I+D Controller Action

- TRANSIENT response analysis study.

- USB/RS 232 / Ethernet/ Modbus Communication

- Ability to hook up with DCS (Distributed Control System Trainer)

Range of experiments:

- Study of multivariable loop, Cascade Control.

- Study of single loop proportional (P), integral (I), and derivative (D) control.

- Study of operation and calibration of transmitters, I/P converter and pneumatic control valve.

- Study of programming and operation of PID controller.

- Study of stability of dual loop cascade control system (Flow – Level Control).

- Study of Rotameter, capacitance type level sensor & control valve.

- Study of SCADA Application Software/ Computerized Control of Cascade Control System.

- Auxiliary Experiments.

Features: -

- Compact Ergonomic Design.

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, Sturdy Piping & Robust Construction.

- Enhanced Electrical Safety Considerations.

- Training Manuals & mimic Charts for Operation Ease.

- System Frame with Caster Wheel Arrangement for ease in movement.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Inbuilt Safety Measures to avoid improper usage.

- Computer Interface & SCADA software connectivity for analysis of Cascade Control Loop (Optional).

- System Dimension: 4.5 Ft. (L) X 2 Ft. (W) X 5 Ft. (H)

- Weight: Approx. 80 Kg

|

TECHNICAL SPECIFICATION |

|

|

Sump tank |

Material: Stainless Steel, 1.5 mm thick/PP 5 mm thick, Capacity: 30 litres, with cover, Dimension: 1ft (L) Χ1ft (W) Χ 1ft (H). |

|

Level Tank |

Material P.P. 5mm thick, Dimension: 150(L) mmΧ150(W) mmΧ600(H)mm |

|

Piping |

½” Class B GI, with ½” SS ball valves: 08 Nos. |

|

Centrifugal Pump |

½ / ¼ H.P., 1f 230 V AC supply, Surface mounting. |

|

Flow meter |

½”, turbine type (WFM type), Range: 0-600 / 0-1000 LPH. Output: 4-20mA, Type: 3 wire type, Supply: 24 V DC, 100 mA, Mounting: Horizontal, Connection:½” |

|

Level Transmitter |

Input: 0-400 / 0-500 mm, Output: 4-20 mA, Supply: 24 V DC: 100mA Type: 2-wire Capacitance type, Mounting: Top 2” screwed connection. |

|

Level Switch |

Float operated, Float Material: SS304, Switching Current:0.5A, Switching voltage: 240 VAC \ 200 VDC, Switch Action: Reversible, Weight: 150 Gms |

|

Pneumatic Control Valve |

Size: ½”, Type; Two way Globe type (Air to Close), CV: 5 US GPM with diaphragm actuator, Equal Percentage Type, Flange connection: PCD: 60mm, ID16 mm, OD: 90mm. |

|

Rotameter |

1 no. Range: 0-1000 LPH, Glass tube type/ Acrylic body, Connection: ½”, Bob material: SS 304, Mounting: Inlet Bottom Outlet Top. |

|

E/P Converter |

Input: 4-20 mA, Output: 3-15 psi, Connection: ¼” NPT /BSP. |

|

A.F.R. / F.R.L. |

Unit- 0-10 Kg/cm2 with pressure gauge, Connection: ¼” NPT /BSP. |

|

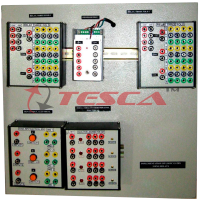

Electronic PID Controller |

2 no. Single input PID (1 N0.) & Dual input (1 No.), With Serial PC Interface (ASCII Protocol) USB / Ethernet / RS 485/ RS 232, Cut out Size: 92mm×92mm×144mm, Input: 4-20 mA, Output: 4-20 mA, Display: Dual for PV & SP, Bar graph display for Output & deviation. Hi-Low Alarm annunciation. |

|

52202 SCADA Application Software (Optional)- |

SCADAS/W, PID control setting(P,PI,PD and PID mode),Auto/Manual Tuning of PID, Data Storage, Off Line analysis, Online Data Acquisition, Simulation and Printing of data in Graphical and tabular form. Interactive Graphical User Interface (GUI) includes. |

|

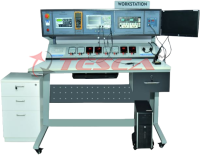

Electrical Control Panel |

MS Powder coated panel with switches, Indicator, test Points, Controller on front facia, UK 2.5 Terminal Connectors mounted on DIN rail Channel. Dimension: 1ft (L) ×1ft (W) ×1ft(H) |

|

52201 Computer (Optional) |

PC with color monitor: 18.5”, Intel Core i3, 500 GB HDD, 4GB RAM, Keyboard & Mouse, DVD Writer, With supporting OS and Communication port. |

|

52203 Air Compressor (Optional) |

Tank capacity: 25 Litres, Discharge: 2 CFM Motor: 1 H.P. 230 V AC Operated, Working pressure: 5-6 kg/cm2 |

Services Required:

- Electric supply 1f 230VAC, 50Hz.

- Water Supply and Drainage Arrangement.

- Clean, dry Compressed air supply at 2.1 Kg/cm².

- Laptop/Desktop computer (for SCADA)

91-9829132777

91-9829132777