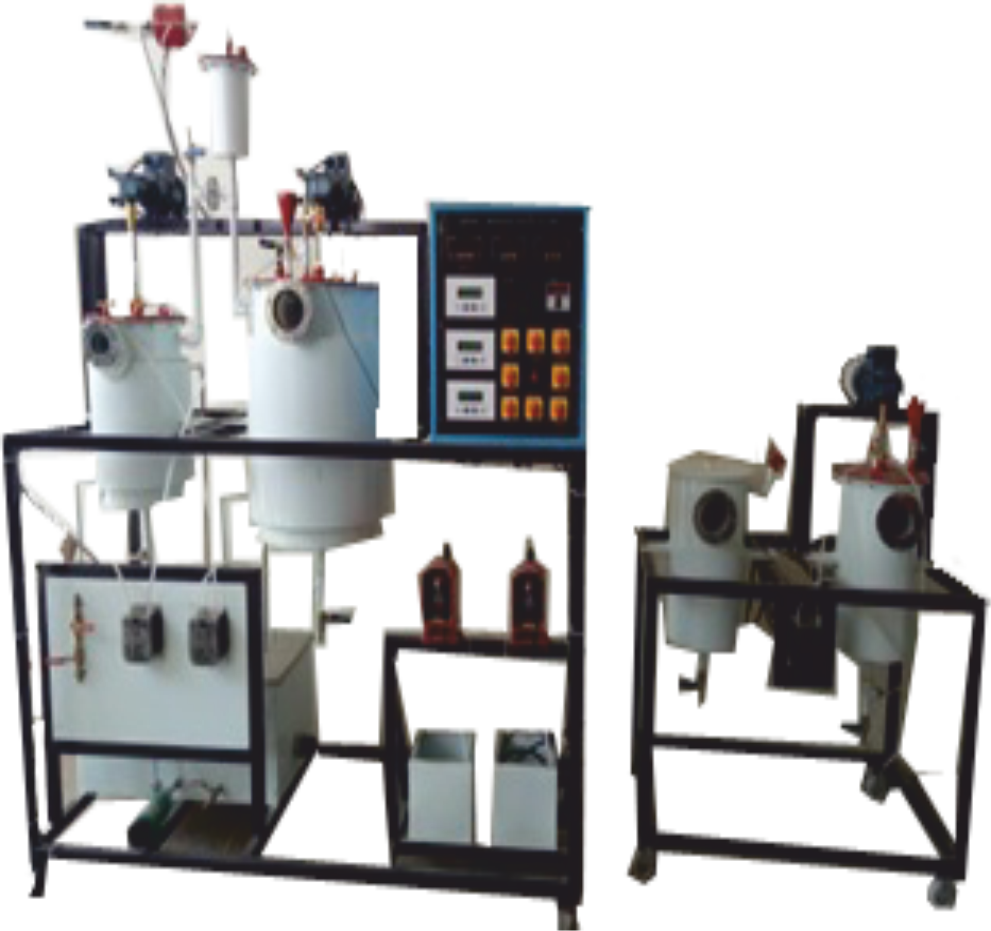

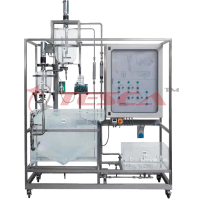

Biogas Pilot Plant

Order Code: 14273

Category: Environmental Trainers

Introduction: This unit serves to demonstrate the generation of biogas in a practical manner. The substrate is a suspension of shredded organic solids. It is hydrolysed and acidified in the first stirred tank reactor. Here, anaerobic microorganisms c...

SPECIFICATION

Introduction: This unit serves to demonstrate the generation of biogas in a practical manner. The substrate is a suspension of shredded organic solids. It is hydrolysed and acidified in the first stirred tank reactor. Here, anaerobic microorganisms convert the long-chain organic substances into short-chain organic substances. The biogas forms in the second stirred tank reactor in the last step of the anaerobic degradation. It contains mainly methane and carbon dioxide. This two-stage method enables the ambient conditions to be adjusted and optimised in both reactors separately. The digestate is collected in a separate tank.

Specifications: Main metallic elements made of stainless steel.Diagram in the front panel with distribution of the elements similar to the real one.20 L reactor vessel with a tubular membrane inside.Lid for the reactor with a manual valve and the respective holes.Heating or cooling coil.Thermostatic bath (up to 60 ºC ), 6 l capacity, 600 W.Pump for hot water circulation of the thermostatic bath.Air compressor, range: 0 – 5 l/min.Diffusion plate for the air inlet.Air flow meter, range: 0.4 – 5 l/min.Peristaltic pump, range: 0 – 0.05 l/min. Water flow meter, range: 0.004 – 0.05 l/min.Membrane, muds separation.Overflow for the outlet of filtered water.Valve on the bottom for mud extraction.Temperature, pH and dissolved oxygen meter to monitor the digestion.Control panel, including: Switch for pump for the hot water circulation. Switch for peristaltic pump. Switch for air compressor.Main switch.

91-9829132777

91-9829132777