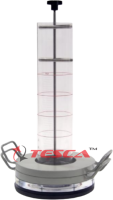

Basic Water Cooling Tower

Order Code: 32046

Category: Fluid Mechanics Lab

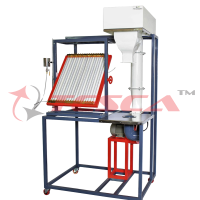

Tesca Basic Water Cooling Tower has been designed to give students an appreciation of the construction, design, and operational characteristics of a modern evaporative cooling system. The unit is also an excellent example of an 'open system' ...

SPECIFICATION

Tesca Basic Water Cooling Tower has been designed to give students an appreciation of the construction, design, and operational characteristics of a modern evaporative cooling system. The unit is also an excellent example of an 'open system' through which two streams of fluid flow (water and air) and in which there is a mass transfer from one stream to the other.

Study of the different parameters of the Cooling Tower system & its calculation is the focus of this trainer. The system has the unique feature of demonstrating heat transfer by cooling tower process including water to air heat transfer. Tesca has designed the system in such a faction that heat transfer by cooling tower principle & its components can be easily understood. The system can easily operate; demonstrated & requisite experimentation can be performed. The system is manufactured from components used in cooling towers used in Industry. The system is mounted powder coated M.S. Structure. The system is self-sufficient for experimentations & study of the cooling towers.

Convincing energy and mass balances are obtained and students can quickly investigate the effects of:

Air flow rate

Water flow rate

Water temperature

Cooling load

Packing density

On the performance of a cooling tower.

System Features:

Mobile, compact, comprehensive, sturdy design

Complete instrumentation for the Study of the Cooling Tower process.

Analysis of heat transfer through Cooling Tower.

Fault Trainer as optional attachments.

System Components:

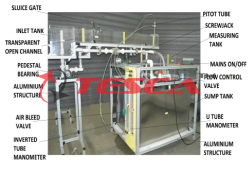

Cooling tower: Made of Clear Acrylic, Size 12” x12”x48”.

Centrifugal pump: ½ hp.

Axial Air Blower

Hot water Heaters

Digital Temperature Indicator: 8 Channel

Temperature sensor: RTD (Pt100)

Dry / Wet Bulb Thermometer: 2 Nos

Makeup water tank

Rotameter for water flow

Blower speed regulator

Electrical switches & indicators

List Of Experiments:

1. Demonstration of cooling tower cycle.

2. Study of the performance of cooling tower systems under laboratory conditions.

3. Study of Mass & Energy transfer.

4. Plotting of different states of air on the psychrometric charts.

Optional Accessories:

Fault Trainer.

Data logging software

Multimedia Software.

Set of Transparencies & Charts.

Operation & Maintenance Manual:

A self-explanatory operating & maintenance manual will be provided. This will include Theory, operating procedure, standard results, and maintenance procedures.

Service Required At Site:

Electric Supply 220/230/240V 50Hz. With proper earthing.

Tap Water supply & drainage

91-9829132777

91-9829132777