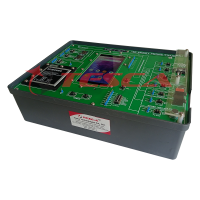

Basic Refrigeration Trainer

Order Code: 10922A

Category: Consumer Electronics Trainers

The training unit shows the domestic coolers, Freezers and autonomous air conditioning units with a heat exchanger / condensers Co-axial tube in tube. Evaporator and condenser sighted glass tubes at inlet and out let. Aluminum ?n, copper tube e...

SPECIFICATION

The training unit shows the domestic coolers, Freezers and autonomous air conditioning units with a heat exchanger / condensers Co-axial tube in tube.

- Evaporator and condenser sighted glass tubes at inlet and out let. Aluminum ?n, copper tube evaporator with variable speed fan for load adjustment.

- Water cooled condenser with standard hose connections and ball valves to meter water ?ow.

- A combination low and high pressure control in the circuit at all times to prevent damage to the compressor.

- Thermostatic control with a range of –30°F to 100°F.

- High pressure cutout in the circuit at all times to prevent damage to the compressor.

- Evaporator coolant discharge determined by either the capillary automatic expansion valve (AXV).

- Aluminum fine tube evaporator for load adjustment with variable speed fan. Air cooled condenser for testing air with regular pumps and ball valves.

- A high pressure and low pressure control combination to eliminate compressor failure at all points in the circuit.

- Thermo control scale of – 30 ° F to 100 ° F. Thermo control.

- At all times high pressure circuit cut off to prevent

- Compressor damage.

Electrical specifications:

- 120VAC; 60Hz; 15AA

- Using Refrigerant HFC 134a

- Complete Size: 34.5′′ L x 18′′ W x 77.5′′ H

- 1⁄3 HP reciprocating compressor, hermetically sealed.

- 1⁄4 “thick HDPE panels of steel reinforced part shelf parts

91-9829132777

91-9829132777