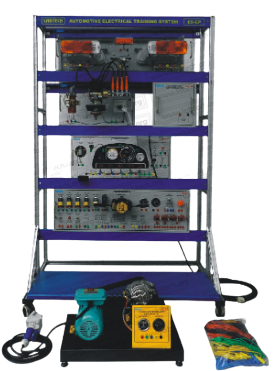

Automotive Electrical Training System

Order Code: 22235575.3.17

Category: General Lab Equipment I

The Electrical Practical Training Board System should be designed to realistically simulate the electrical system on an auto mobile. The unit should consist of a number of modular demonstration panels, which should be mounted on a wheeled stand with ...

SPECIFICATION

The Electrical Practical Training Board System should be designed to realistically simulate the electrical system on an auto mobile. The unit should consist of a number of modular demonstration panels, which should be mounted on a wheeled stand with special powder coated aluminum rails, for Plexiglas panels, which gives secure and firm fitting modules. Also should contain a power source and component connecting cables. Them components featured should be real original parts as commonly used in automobile typically produced by the major car or component manufacturers. The system could be used in the classroom as a demonstration unit to show students various types of wiring and to familiarize them with typical car electrical systems. Also it could be used as a trainer with the student performing actual wiring exercises with the various components.

1. Requirements:

- The Original components should be mounted on clear Plexiglas panels that allow high visibility of all parts and wiring.

- Panels should be fixed vertically to a frame which should be mounted on a heavy-duty aluminium frame mobile stand.

- Vertical presentation of panels should simulate the schematic presentation of common vehicle wiring diagrams.

- Panels should feature wiring guides and icons which have been silkscreened onto the panels so as to familiarize the student with schematic type wiring diagrams.

- The wires of each component should be brought to 4mm wiring terminals/safety sockets mounted on the panel.

- Connection of the components should be easily accomplished by using the cables with stackable 4mm plugs that are provided.

- A 12 Volt DC transformer that duplicates the power as supplied by a car should furnishes power to the components.

2. Modules:

1. DASHBOARD PANEL

The panel should have a central control and switching panel containing an ignition switch, turn signal switch, hazard light switch, brake light button, high/low beam headlight switch,headlight on/off switch, fog light switch, horn switch, reverse lamp button, passing light switch, ampere meter, voltage meter, fuse box and various relays. Panel should have a special central power switch to quickly cut off all power for safety.

2. INSTRUMENTATION PANEL

The panel works in conjunction with the dashboard panel and provides extra instrumentation as found in many vehicles such as tachometer, speedometer, instrument panel light, high beam light indicator, open door lamp, fuel gauge with sender, charging lamp, water temperature gauge with indicator lamp, oil pressure lamp, left and right turn signal indicator.

3. REAR LIGHTING PANEL

Should feature two tail light units (with turn signals, brake lights, parking lights and reverse light), a 3rd brake light and license plate light.

4. FRONT LIGHTING PANEL

Should feature two headlights, two fog lights, two turn signals/parking lights and a horn.

5. CONVENTIONAL IGNITION PANEL

Should have a conventional breaker-point distributor (4cylinder) which is driven by an electric motor, 12 Volt ignition coil and four functional spark plugs. Note the distributor can be “timed” by using the pulley on the electric motor and timing light. Various engine speeds can be simulated by controlling the speed of the

electric motor with the rheostat control provided.

6. ELECTRONIC IGNITION PANEL

Should feature an electronic ignition distributor (4 cylinder) which is driven by an electric motor, 12 Volt ignition coil,electronic control and four functional spark plugs. Note the

distributor can be “timed” by using the pulley on the electric motor and timing light. Various engine speeds can be simulated by controlling the speed of the electric motor with the rheostat control provided.

7. DIESEL IGNITION PANEL

Should contain two glow plugs, diesel ignition switch, glow plug pre heater indicator.

8. ACCESSORIES PANEL

Should contain common accessories found in vehicles such as windshield wipers with motor and switch, cigarette

lighter, dome light, courtesy light, interior light and door open senders, ventilation blower motor with switch.

9. RADIO PANEL

Should contain a typical car radio/cd player with speaker, and antenna system.

10. TRAILER PANEL

Should feature a multi pin standard trailer to vehicle electrical coupling with brake light, parking light, reverse light and turn signal light as would becontained on a trailer.

11. ALTERNATOR TEST SYSTEM

The system should be a bench top unit designed to operate and demonstrate the alternators below. Unit consists of an electric motor to drive the alternator units, amp meter, volt

meter and various other demonstration circuits

12. ALTERNATOR (A/C)

The unit should be a semi sectioned original automotive alternator is designed to operate with alternator test system in order to provide an example of A/C generating system for an automobile.

13. STARTER MOTOR

Should be a semi-sectioned original starter motor that is mounted on a base plate which features electrical connection terminals. The starter is operable and some internal parts are visible during operation.

14. THEFT ALARM PANEL

The panel should feature a standard theft alarm system (after market type) which is designed to discourage auto break-in and theft.

15. CENTRAL LOCK PANEL

Should have 2 station central lock system for automobile doors with key type and central controls.

16. POWER WINDOW PANEL

Should contain one power window mechanism with door mounted and central switch controls. Also features a

window lock device which is usually near the driver’s position.

3. Additional Equipment

A. Four level mobile floor stand

B. 12 volt dc power supply (input 110/220 volt, 50/60 hz)

C. Storage cabinet for modules

4. Accessories:

Assortment 100 pcs (Electrical Lead Sets with 4mm Plugs)

To come complete with comprehensive course ware, operational manual and student job sheets which provide detailed exercises.Sample Training experimental manual to be provided during the bidding process to ensure all experiments are met.Sample Training experimental manual to be provided during the bidding process to ensure all experiments are met.

91-9829132777

91-9829132777