Automation Trainer Kit / Industrial 4.0 Automation

Order Code: 54035

Category: Mechatronics/ Robotics/ CNC Lab

Tesca’s comprehensive line of automation training systems focuses on advanced smart manufacturing, robotics, and mechatronics technologies. Such training programs improve technical skills in automation from the fundamental subjects of robot ope...

SPECIFICATION

Tesca’s comprehensive line of automation training systems focuses on advanced smart manufacturing, robotics, and mechatronics technologies. Such training programs improve technical skills in automation from the fundamental subjects of robot operations and device adjustment to advanced subjects such as serial appliances and station control.

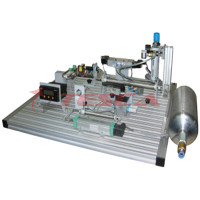

Station 1

Weighing & Palletizing Station

The station is designed to test the product, height and weight of material before the robotic arm is used for palletising. Parts are put on the conveyor belt and sensors are identified and rotational arm triggered to pick and position weighing and then the palletize using robot.

The system consists of: belt conveyor, different types of sensors has used based on the applications, rotational pick & place, weighing, robot, pallet, pneumatic system. It is easy for the teacher to teach on troubleshooting of automation system and Students will gain their problem solving skills with Tesca Automation system trainers.

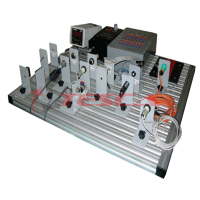

Station 2

Linear Transfer Using Two types of Conveyors.

The Tesca system demonstrates the principles of automatic transport & sorting with horizontal transfer unit and pick & place robot.

This station is designed to demonstrate common transmission mechanisms in mechatronic systems. The components that are located on the conveyor are sensed and moved into position through a horizontal transfer unit A robot arm takes the component into a rotary index and a second robot arm places the component into a container. The device can be reconstructed to create different process and configured using the PLC software by repositioning modules.

List of Experiments

- Understand how the factory automation works.

- Learn about Types of Linear conveyor

- Learn about PLC programing

- Study different types of sensors working principles

- Understand about pneumatic components

91-9829132777

91-9829132777