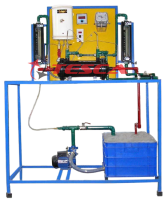

Vapor Liquid Equilibrium Apparatus

Order Code: 32313

Category: Thermodynamics Lab

Features Scientists distinguished between synthetic method and analytical method for high pressure VLE measurement. In the former method, a mixture of known composition prepared and its behaviour is observed as a function of temperature and pressure...

SPECIFICATION

Features

Scientists distinguished between synthetic method and analytical method for high pressure VLE measurement. In the former method, a mixture of known composition prepared and its behaviour is observed as a function of temperature and pressure, the problem of analysing the equilibrium compositions is thereby avoided. In analytical method overall compositions are not at issue. Temperature and pressure is adjusted to bring about phase separation and withdrawn samples are then analysed.

A simpler classification is based on whether either the liquid or vapour, or both, are circulated through equilibrium chamber. If circulation takes place it is classified as dynamic or flow method, otherwise it is a static method.

It consists of the following:

1. An equilibrium cell in which the vapour and liquid phases of the mixture are in equilibrium.

2. An environment that controls the temperature of the equilibrium cell, e.g. air bath, oil or water bath etc.

3. A procedure for agitating and mixing the cell contents, e.g. stirrer.

4. A method for sampling the liquid and vapour phases.

5. A means for accurate analysis of the withdrawn samples.

6. Pressure and temperature measuring devices.

Tesca Static Method for VLE Measurement

The features of a typical static apparatus are shown in figure 2. An equilibrium cell is filled with each component of the mixture to be studied. The mass of each component introduced is determined by weighing. The cell is kept at constant temperature in an air thermostat and the mixture is stirred with magnet. At equilibrium, pressure is read and sample of both the phases are withdrawn and analysed. The cleaned and degassed cell is weighed. Then the liquid component is introduced, cooled and degassed by stirring under vacuum. After degassing, the cell is weighed to determine the mass of the liquid component. Then the cell is connected to the filling equipment to introduce the gaseous component. A known amount of gas is introduced. The exact mass of the gaseous component is determined by weighing the cell accurately. The filled cell is connected to the apparatus and fixed on a rigid support to allow easy handling of the sampling valves without constraints on the tuning and welded parts of the cell. The air thermostat and magnetic stirring are activated to reach the equilibrium conditions. When the temperature and pressure are constant, the samples are withdrawn through the sampling valves to perform phase analysis .The pressure inside the cell is higher than that in chromatographic circuit, and therefore the sample flows through the stem of the sampling valve. After the sampling valve is closed, the sample is taken out by the carrier gas upto thermal conductivity detector. CG

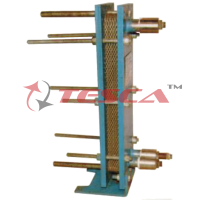

Tesca Dynamic VLE Measurement Using Flow Type Apparatus

The apparatus is composed of a feed system, preheater, equilibration system and sampling system. All parts exposed to high temperature are made of SS316.The details of the apparatus are shown in figure 3.A gaseous component, such as CO2, cooled and liquefied in a water heat exchanger. The liquefied component was then pressurized through a plunger pump and supplied to a buffer tank immersed in a water bath which allowed the component to be heated to its supercritical temperature. A liquid component was provided through a non pulsating pump and joined in a tee zone with the gaseous component supplied from the buffer tanle This mixture was heated when passing through a preheater tubing fitted with an electric line heater .In another tubing immersed in an air bath, the temperature of the mixture was adjusted to a desired equilibrium temperature. Then it flowed into a static mixer and was well mixed in order to ascertain the attainment of equilibrium state in a short time before the separation of vapour and liquid phases in an equilibrium cell. The liquid phase flowed out constantly from the bottom of the cell through a metering valve, while the vapour phase exited from the top of the cell. A small amount of liquid and vapour phases are taken in the separate samplers and are analysed by gas chromatography.

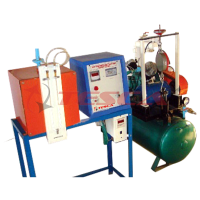

Tesca VLE Measurement Using Thin Film Evaporator

The experiment was conducted using aqueous solution of formaldehyde and methanol.

The apparatus used for investigating VLE is a thin film evaporator in which a rotating coil spreads the liquid feed on the inner surface of a tube surrounded by a heating jacket. The liquid partially evaporates. The coexisting phases are separated and collected in vials. Experiments can be carried out at small evaporation ratios and high residence times so that chemical equilibrium in the liquid phase leaving the apparatus is achieved. The temperature of the coexisting phases is measured by platinum resistance thermometry and pressure using differential pressure transducers. Either gas chromatography or wet chemistry was used for analysing the composition of the coexisting phases.

Tesca VLE can be applied for measuring equilibrium data and evaluation of equilibrium curves. These curves are used for the calculation of necessary separation efficiencies of distillation columns.

1 universal glass apparatus, complete with silvered vacuum mantle, cooler, circulation evaporator and vacuum tight screwing for sample take-off by means of a syringe, with works certificate “Operation Pressure”.

1 immersion heater 350W, with special surface finish to avoid bumping.

1 magnetic stirrer for intensive mixing.

10 final receivers with screw caps.

1 feed burette 250ml, graduated with plastic coating.

2 solenoid coils.

1 liquid temperature sensor Pt-100, with connection cable and plug.

1 vapour temperature sensor Pt-100, complete with connection cable and plug, optionally calibrated.

1 Phase Equilibrium Controller MINITRON (VLE)2 with modern micro-electronics, offers high operating comfort, safety and reliability, with menu guided operation by push-turn-knob.

Connectable to a PC for data input, data display and storage by means of an interface.

91-9829132777

91-9829132777