Twist & Bending Machine

Order Code: 32211

Category: Strength of Materials Lab

Features Torsion is a type of effort that appears when applying a momentum or force on a bar or element. The transverse sections of the bar suffer a twisting around an axis normal to its plane where tangential efforts analogous to the si...

SPECIFICATION

Features

Torsion is a type of effort that appears when applying a momentum or force on a bar or element. The transverse sections of the bar suffer a twisting around an axis normal to its plane where tangential efforts analogous to the simple shear efforts are developed.

Bending is another type of effort (deformation) that appears in a long structural element in a direction perpendicular to its longitudinal axis. Bending moments are caused by the application of loads normal to the longitudinal axis of the element, generating a bend.

Tesca Twist & Bending Machine is a combined apparatus for the demonstration of both twist and bend to be used in the laboratory or as a complement of the theoretical study about twist and bend. Its size and weight facilitate its transport and make it ideal to develop the practical exercises.

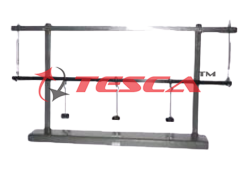

The 32211 unit consists of two transverse guides on which the beam supports slide. The supports can be placed different distances apart, thus the student can check the effect produced by this variation in the deformations of the beam subjected to flexion or torsion efforts.

In flexion experiments, the student will be able to calculate the Elasticity Modulus of different materials, demonstrating the relation load- deformation.

In torsion experiments, the student will also be able to check the relation load-deformation and get the Rigidity Modulus of different materials.

The test pieces used for flexion experiments are made of stainless steel with different rectangular cross sections. Therefore, circular section test pieces of different materials can be used.

The test pieces used for torsion experiments are made of different materials and with circular cross sections, what will allow the student to compare the Rigidity Modulus of different materials. A dial gauge with its assembly accessories is supplied to measure the beam deformations both in flexion and torsion experiments. To complete the supply, a set of weights adequate for the unit is provided, with hooks adapted to each type of experiment.

Specifications

Twist & Bend Machine, which allows to carry out both types of experiments.

Bench-top unit with structure made of anodized aluminum profiles, with painted steel panel.

It is mounted on 4 adjustable in height rubber legs.

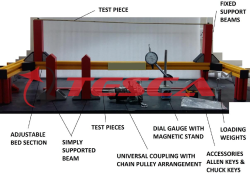

It consists of two stainless steel guides of 800 mm, which allow to displace the supports in the whole range. This allows the student to carry out the experiment of beams of different length.

4 Test pieces with circular section, of 8 mm diameter, of different materials (steel, aluminum, brass, bronze). They have marks every 50 mm to make the measurement of the beam length easier.

7 Test pieces with different rectangular cross section made of stainless steel. They also have marks every 50 mm to make the measurement of the beam length easier.

Dial gauge of 0-10 mm to measure the deformations with 0.01 mm. accuracy. The elements required to perform the practical exercises are supplied:

Allen key of 3 mm to assemble the beams in the supports.

Set of weights adapted to the MTP unit with special hooks for each type of experiment:

2 weights of 10 N.

4 weights of 5 N.

Manuals: This unit is supplied with the following manuals: Required Services, Assembly and Installation, Starting-up, Safety, Maintenance & Practices Manuals.

Experiments

1. Study of the beams flexion for different sections and lengths.

2. Determination of the Elasticity Modulus for stainless steel.

3. Study of the relation between the torsional moment, beam length and torsion angle of one shaft.

4. Determination of the Rigidity Modulus for steel, bronze and aluminum

91-9829132777

91-9829132777