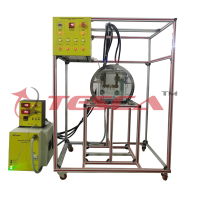

Tray Drier

Order Code: 32293

Category: Thermodynamics Lab

Features Designed to demonstrate operation Tray Dryer. Real Time Data Acquisition System with graphical representation. Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices. Tesca Tray Dryer Unit is ...

SPECIFICATION

Features

Designed to demonstrate operation Tray Dryer.

Real Time Data Acquisition System with graphical representation.

Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices.

Tesca Tray Dryer Unit is designed to demonstrate process of drying using Tray Dryer. The unit resembles the most commonly used industrial method of drying solids in bulk where hot air stream is passed over fixed trays of wet material. Students will able to vary the operating conditions and collect data to demonstrate both the theoretical and practical aspects of industrial drying practice.

A fan draws air in to the duct where it gets heated as it passes over the Heaters. This hot air then flows over the trays which hold the material to be dried. Measuring instruments record Air Temperature & humidity at different points, Air Flow etc.

Lab VIEW software provides real time data on computer

screen along with graphs & tabular results. Detailed Operation & Maintenance Manual is provided along with the trainer.

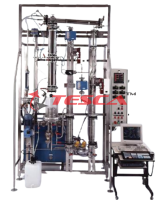

Specifications

Drier for investigating convection drying of solids

Drying on 4 corrosion resistant plates in a drying channel with an airflow adjustment of air velocity via speed of fan

Air heating with controlled heaters

Digital balance for measuring the change of weight during drying

1 combined sensor for measurement of humidity and temperature before and after the solid sample

1 air velocity sensor

Digital stopwatch , battery operated

Lab VIEW software for data acquisition via USB under Windows XP or Windows Vista.

Wheeled AISI 304 stainless steel structure

AISI 304 stainless steel channel with window (approx. 450x450 mm)

Fan with digital speed control, 0 to 4 m/s

4 aluminium trays of approx. 400x300 mm, total capacity of approx. 3.5 kg of solid.

Adjustable battery of electric heaters , P max around 2.5kW

2 digital thermo-hygrometers

Digital chronometer

Digital anemometer for air flow rate measurement

Electronic balance

Switchboard IP55, with plant synoptic and ELCB and emergency pushbutton

Experiment Capabilities

Mass and energy balance

Drying processes

Mass and heat transfer

Air speed and temperature effects on drying process

Services Required

Electric Supply 220 - 240V AC, 16 A, Single Phase, Earthed.

91-9829132777

91-9829132777