Steam Boiler Unit, Gas Oil Fired, 32KW

Order Code: 32467

Category: Boiler & Steam Generators

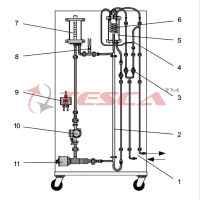

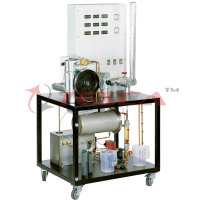

Tesca Steam Boiler Unit 32467 consists of a sturdy framework and panels of all steel construction, fitted with a student work surface, interconnecting back panel and adjustable feet. Adjacent and connected to the framework is an electric steam boi

SPECIFICATION

Features

- Safe automatic boiler operation

- Low capital cost

- Compact modular design offering easy installation

- Comprehensive instrumentation

- Fully certified design

Tesca Steam Boiler Unit 32467 consists of a sturdy framework and panels of all steel construction, fitted with a student work surface, interconnecting back panel and adjustable feet.

Adjacent and connected to the framework is an electric steam boiler of 36 kW rated output. The heat input to the boiler is provided by specially designed electrical resistance immersion elements run at a low power density in order to give a long operational life. The boiler, with its attendant mains water make up tank, feed pump, steam main, blowdown, drain and feedwater connections is housed in a self-contained unit.

The student desk unit contains a control box with an electric power supply isolator and instrumentation to read steam and water temperatures and also to display the electrical energy consumed in kWh. All piping and wiring required to connect the boiler to the steam benches is supplied.

Boiler Fully automatic electric boiler or works with gas-oil, with a useful power of 32 kW, operated by a three probe electronic circuit system which controls the boiler feed pump and also provides integral fail safe ‘low water’ protection. The boiler heating is controlled by a pressure switch system. The boiler is fully insulated and housed in a mild steel jacket. Fitted with:

- Boiler blow down valve with discharge to bench blow down line

- Pressure relief valve and discharge line with condensate drain

- Pressure control unit

- Bourdon type pressure gauge 0 to 20 bar

- Steam output line with integral type K thermocouple and stop valve

Specifications

- Automatic Electric 36KW or Stage gas-oil burner of 32 kW, computer controlled.

- Circulation pump, computer controlled.

- Closed expansion tank.

- Safety valve (3 bar).

- Air purger.

- Safety thermostat.

- Drain valve.

- Portable tank for fuel of 20 l.

- Fuel filter.

- Chimney made of stainless steel:

- Adapter at the outlet of the boiler.

- “T” of 90 ºC. Two elbows of 45 º. Two straight sections of 930 mm. Cone for free outlet. Two wall clamps.

- Three-ways electronic valve, computer controlled, which distributes the water heated by the boiler-burner group into two primary circuits. One of them is the double jacket of the hot water tank to obtain domestic hot water, and the other is the radiator to generate heating.

- Hot water tank with double jacket made of stainless steel with a capacity of 150 l.

- Solenoid electrovalve, computer controlled, in the tap water inlet line to the hot water tank.

- Fin radiator of five elements and purger. Methacrylate receptable where the radiator is located. It is possible to control the temperature in the receptacle by means of a PID control through the software that acts on the threeways solenoid valve. The receptacle has a room thermostat inside, which also makes it possible to control the heating temperature.

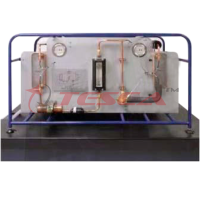

- Nine temperature sensors “J” type, at the key points of the unit, to measure:

- Temperature of the hot water leaving the boiler.

- Temperature of the water outlet and inlet of the hot water tank primary circuit and the radiator.

- Temperature of the domestic hot water inside the hot water tank and the domestic hot water outlet.

- Temperature of the primary circuit´s water that recirculates to the boiler.

- Gas-oil flow sensor to measure the fuel flow consumed by the boiler, range: 0.4 – 4 kg/h.

- Three water flow sensors, range: 1.5 – 30 l/min, to measure:

- Water flow used for the primary circuit of the hot water tank.

- Water flow used for the primary circuit of the radiator to generate heating.

- Tap water inlet flow into the hot water tank.

- Combustion gases analyzer for the measurement of CO, CO2, O2, air excess, temperature of the combustion fumes, combustion efficiency, etc.

Feed Tank

Double jacketed constructed from stainless steel with a capacity of 150 litres.

Fitted with:

- Pump suction line with pre-pump isolating valve, strainer and type K thermocouple

- Water supply line (untreated, unless used in conjunction with Water Treatment Studies Unit), complete with ballcock valve and stop valve overflow outlet

Boiler Feed Water Supply

Centrifugal water feed pump automatically operated by boiler water level controller

Feed line fitted with one way check valve

Instrumentation (Optional)

A solid state kilowatt hour meter with 8 digit alpha-numeric display

A digital temperature indicator

Experiments

- To determine the boiler evaporation capacity and equivalent evaporation

- Boiler efficiency trial

- To assess the heat

Required Water Supply:

The boiler consumes 60 litres per hour and it is recommended that the water is treated to attain a minimum quality as follows:

- Total hardness in terms of Ca Co³: max 2

- Caustic alkalinity in terms of Ca Co³: 300 ppm

- Total Dissolved Solids:

- recommended level: 500 ppm

- max. allowable level: 2000 ppm

- pH Level: 8 – 10

Free from corrosive gases such as oxygen and carbon dioxide

Requirements:

Mains Power: 380 – 440V AC, 3 Phase, 50Hz, Rating @ 50KW

91-9829132777

91-9829132777