Single Effect Falling Film Evaporator

Order Code: 32298

Category: Thermodynamics Lab

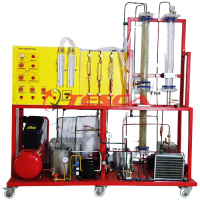

Condenser, a metering pump and a liquid-ring vacuum operation. The apparatus includes two glass tank for collection of evaporated solvent and concentrated product. The evaporator is used for separation of oxygen from air flow by absorption in counter...

SPECIFICATION

Condenser, a metering pump and a liquid-ring vacuum operation. The apparatus includes two glass tank for collection of evaporated solvent and concentrated product. The evaporator is used for separation of oxygen from air flow by absorption in counter flow with a water film. A compressor is used to supply ambient air to the trainer while 2 pumps are used for circulation of solvent through absorption & desorption column. 2 hand-held measuring units for measuring the oxygen concentration upstream and downstream of the absorption column.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications

The unit comprises the following main items:

Wheeled AISI 304 stainless steel structure, piping and valves of AISI 304 and AISI 316 stainless steel

AISI 316 stainless steel metering pump

Liquid-ring vacuum pump, P=0.7 kW approx

2 Bourdon pressure gauges

Bourdon vacuum gauges

Borosilicate glass feeding tank , with capacity of 25 I approx

2 borosilicate glass collecting tanks, one for concentrated product and the other for condensate solvent. Capacity of 10 I approx. each

Borosilicate glass graduated tank for measuring the condensate, with capacity of 1 I approx.

AISI 304 stainless steel evaporator, shell-and-tube condenser and tube-in-tube heat exchanger

Pneumatic valve for steam flow rate control

Stainless steel calibrated diaphragm with differential pressure transmitter for measuring the steam flow rate

Flow-meter

6 Pt 100 Sensors

Switchboard IP55, with plant synoptic and ELCB and emergency pushbutton complete theoretical- Experimental handbook including exercises, English language mandatory

Features

Designed to demonstrate process of rising film evaporation.

Includes Pulsing Unit with capability to vary amplitude & frequency of Pulsation.

Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices.

Tesca Single Effect Falling Film Evaporator is designed for demonstration of falling film evaporation process. This floor standing pilot-plant unit consists mainly of a falling-film evaporator supplied with shell-and –tube

Experiment Capabilities

Evaporation process

Heat transfer determination

Energy and mass balances

Heat transfer coefficient

Services Required

Electric Supply 230 V AC, Single Phase, Earthed.

Steam Supply : 20 kg/hr @ 2 bar (g)

Water Supply : 25 LPM @ 10 m head

91-9829132777

91-9829132777