Sedimentation Tank Model

Order Code: 32067

Category: Fluid Mechanics Lab

Features: Solid/liquid separation in a sedimentation tank Visualization of flow conditions. Includes Suspension Flowmeter Tesca Sedimentation Tank Model Demonstrator is designed to investigate the factors influencing the s...

SPECIFICATION

Features:

Solid/liquid separation in a sedimentation tank

Visualization of flow conditions.

Includes Suspension Flowmeter

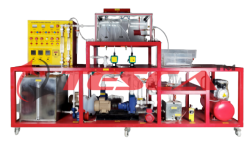

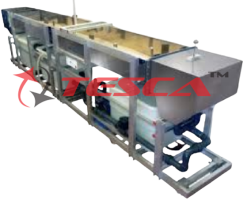

Tesca Sedimentation Tank Model Demonstrator is designed to investigate the factors influencing the separation process in sedimentation tanks. In sedimentation tanks, solids are separated out of suspensions under the influence of gravity. For this, the density of the solid particles must be greater than that of the liquid. First, a suspension of water and precipitated calcium carbonate is prepared in a tank. A pump delivers the suspension to the sedimentation tank. In the inlet area of the sedimentation tank, the suspension intermingles with fresh water. The mixture flows over an inlet weir. On their way through the sedimentation tank, the solids sink to the bottom. The treated water flows out by way of the weir at the sedimentation tank outlet.

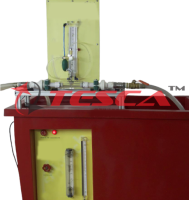

The solid concentrations at the sedimentation tank inlet and outlet are determined by means of two Imhoff cones. The mass separated in the sedimentation tank can be determined from the difference between them. The flow rates of the suspension and the freshwater are adjusted by valves and indicated by flow meters. This

enables the mixing ratio – and thus the solid concentration of the mixture - to be adjusted. In order to ensure a uniform mix of the suspension and prevent premature sedimentation, a portion of the suspension is fed back into the suspension tank by way of a bypass. To investigate the flow conditions, ink can be added with a piston burette to the freshwater stream as a tracer substance. To provide enhanced observation of the flow conditions and settling processes, the sedimentation tank is made of transparent material.

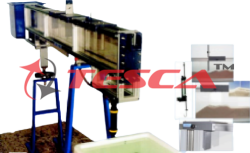

A baffle plate can be positioned in the sedimentation tank to impede the flow. Its horizontal and vertical positioning in the sedimentation tank is adjustable. This enables the flow conditions and the efficiency of the separation process to be influenced.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications:

Sedimentation tank: LxWxH: 1000x400x230 mm, Capacity: approx. 80L, Material: Clear Acrylic

Sump Tank: 120 Ltrs.

Flow Meters: Mains water flow meter range

0.5 - 5.0 litres/ min; slurry flow meter range 0- 2 litres/min.

A dye injection system is incorporated to allow hydraulic tracer and flow visualization studies.

Measuring flow regimes using a dye tracer and comparison of these with idealized flow models.

Effect of variables such as flow rate and baffle position on flow regimes.

Measurement of sediment removal efficiencies

Settling tank: 1000 x 400 x 200mm

Sediment sump tank capacity: 120 liters

Water flow meter range: 0.5-5 l/min

Sediment suspension low meter range: 0-2 l/min

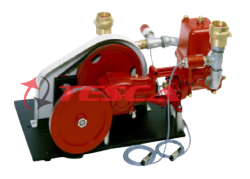

Pump flow rate: 25 l/min at 5m head

Motor: 0.1kW

Experiment Capabilities:

Learning the fundamental principle of separation of solids from suspensions in a sedimentation tank.

Measuring flow short-circuiting and dead space using a tracer.

Comparison of real flow regimes with idealized flow models.

Effect of flow rate and baffle position on dispersion.

Measuring sediment removal efficiencies and relating these to the hydraulic characteristics.

Required Services:

Electric Supply 230 V AC, Single Phase, Earthed.

Tap Water & Drainage

91-9829132777

91-9829132777