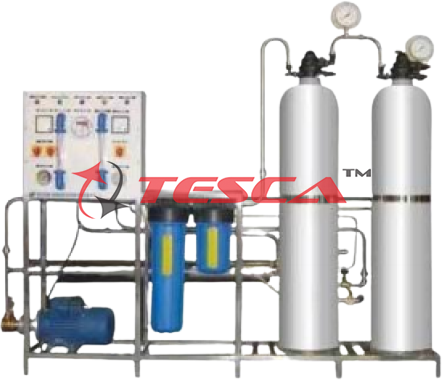

Reverse Osmosis Unit

Order Code: 32302

Category: Thermodynamics Lab

Features Designed to demonstrate Reverse Osmosis process used in distillation of water. Corrosion resistant components used in the trainer. Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices. Tesca...

SPECIFICATION

Features

Designed to demonstrate Reverse Osmosis process used in distillation of water.

Corrosion resistant components used in the trainer.

Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices.

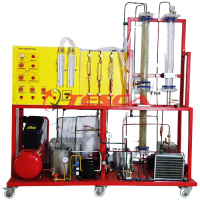

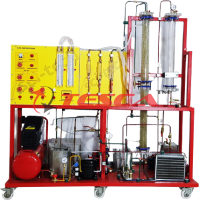

Tesca Reverse Osmosis Unit is designed to demonstrate water distillation using Reverse Osmosis Technique. The setup consists of a raw water tank fitted with stirring machine. A pump draws salty water from the raw water tank to the spiral wound membrane module. The distilled water & concentrated salt solution are separated & can be collected separately or discharged in to the raw water tank. A distilled water tank is provided for flushing the system. Conductivity sensors are provided to measure the salt concentration at different points. Measuring instruments are provided to measure flow rate & pressure at different locations.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Tank for distilled water to flush through the spiral wound membrane module

Tank to collect the permeate

Safety cut out to protect the pump against dry running

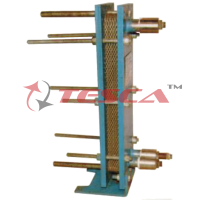

Spiral wound membrane module

Active area:1.2m²

Raw water flow rate max.23L/min

Length: Approx. 500mm Ÿ Diameter approx. 60mm Ÿ Piston pump

Max. flow rate approx. 425L/h

Max head: approx. 700m

Stirring machine

Power consumption: 140W

- Speed 30.. 1000 min¯¹

Tanks

Raw water (salt solution): approx. 110 L

Distilled water approx. 110L

Permeate approx. 5L

Measuring Instruments

Retentate flow rate 0,2 … 6.0L/min

Permeate flow rate 0.05.. 1.8L/min

Temperature 3 x 0.. 50?C

Pressure 2 x 0 .. 120bar

Conductivity: 0… 200mS/cm

Experiment Capabilities

Fundamental principle of reserve osmosis, Van’t Hoff’s law

Permeate quantity and salt concentration in the permeate and retentate dependent on pressure and salt concentration in feed

Determination of membrane constants and retention

Services Required

Electric Supply 230 V AC, Single Phase, Earthed.

Tap water supply & Drain.

Specifications

Removal of solvent from a salt solution using reverse osmosis

Polyamide spiral wound membrane module

Piston pump with pulsation damper for pressure generation

Overflow valve to adjust the pressure upstream of the membrane module

Valve to adjust the retentate flow rate

Raw water tank with stirring machine to prepare a salt solution

91-9829132777

91-9829132777